Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

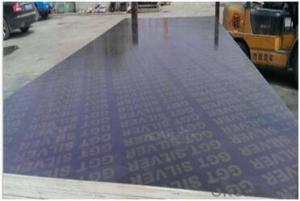

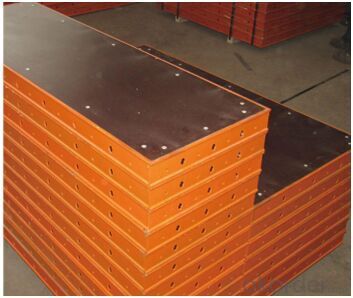

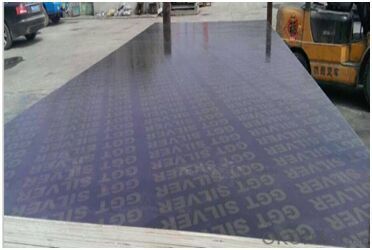

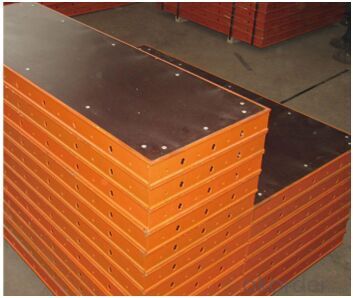

1. Structure of Light Steel Frame Formwork with plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with plywood is quite weighing lightly and work faster.

2. Main Features of Structure of Light Steel Frame Formwork with plywood

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

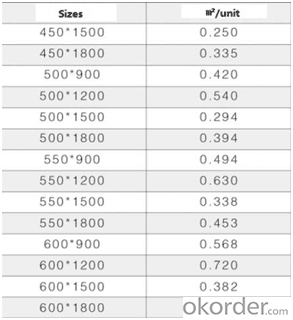

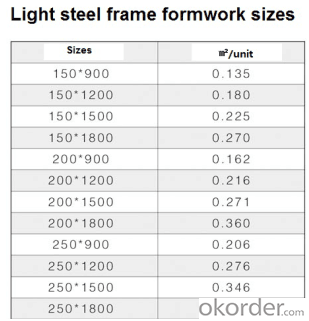

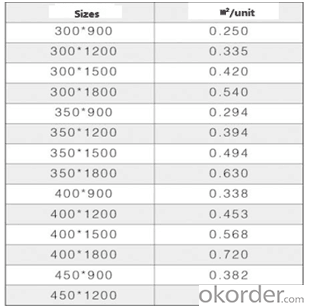

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of formwork hinges used with steel frame formwork systems?

- There are two main types of formwork hinges used with steel frame formwork systems: fixed hinges and adjustable hinges. Fixed hinges are used when the desired formwork angle does not need to be changed, providing a stable and rigid connection between formwork panels. On the other hand, adjustable hinges allow for flexibility in adjusting the formwork angle, making them suitable for projects with varying concrete structures. These hinges offer ease of use and versatility in formwork installation and removal.

- Q: Can steel frame formwork be used for both straight and curved slab construction?

- Absolutely, steel frame formwork is suitable for both straight and curved slab construction. This adaptable system grants the freedom to fashion various shapes and designs for concrete slabs. The steel frames can be easily modified and tailored to meet the specific demands of the project, regardless of whether it involves a straight or curved slab. Consequently, this renders it suitable for an extensive array of construction undertakings, ranging from uncomplicated straight slabs to intricate curved structures. Moreover, the robustness and longevity of steel guarantee a dependable choice for formwork, safeguarding the slabs' form and structural soundness throughout the construction journey.

- Q: How does steel frame formwork handle different types of concrete curing temperatures?

- Steel frame formwork is highly versatile and capable of handling different types of concrete curing temperatures. The steel frame provides excellent strength and stability, allowing it to withstand both high and low curing temperatures without warping or distorting. Additionally, the steel material has good thermal conductivity, which helps in efficiently distributing heat during curing. This ensures that the concrete cures evenly and achieves optimal strength and durability regardless of the curing temperature.

- Q: What are the different types of shoring systems used with steel frame formwork?

- There are several types of shoring systems commonly used with steel frame formwork, including adjustable steel props, aluminum props, modular shoring towers, and hydraulic shoring systems.

- Q: Can steel frame formwork be used in projects with limited project budget?

- Projects with a limited budget can utilize steel frame formwork. Despite its higher initial cost compared to other formwork systems, steel frame formwork offers various advantages that can help offset these expenses. To begin with, steel frame formwork is highly durable and can be reused for multiple projects, minimizing the need for frequent replacement or repair. This durability leads to long-term cost savings for projects with limited budgets. Furthermore, steel frame formwork ensures high-quality finishes, resulting in a smooth and precise concrete structure. This eliminates the necessity for additional finishing work, saving both time and money during the construction process. Moreover, steel frame formwork allows for efficient and speedy assembly and disassembly, reducing labor costs and increasing productivity on the construction site. The ease of handling and transportation also contributes to cost savings. Lastly, steel frame formwork provides excellent structural support, enabling the construction of complex and large-scale structures. This reduces the overall material requirements and associated costs, making it a cost-effective choice for projects with limited budgets. In conclusion, although steel frame formwork may have a higher initial cost, its durability, reusability, high-quality finishes, efficiency, and structural support make it a practical option for projects with limited budgets.

- Q: Can steel frame formwork be used in areas with limited crane access?

- Yes, steel frame formwork can be used in areas with limited crane access. Steel frame formwork is a versatile and flexible system that can be adjusted and assembled manually, making it suitable for areas where cranes cannot be easily maneuvered. The steel frames are lightweight and can be easily handled by a small team of workers, allowing for efficient construction even in areas with restricted crane access. Additionally, the modular design of steel frame formwork allows for easy assembly and disassembly, further simplifying the construction process in areas with limited crane access.

- Q: How does steel frame formwork handle the placement of reinforcement bars?

- Steel frame formwork is a construction system that utilizes a steel frame structure to support concrete during the pouring and curing process. When it comes to the placement of reinforcement bars, steel frame formwork handles it in a highly efficient and effective manner. Firstly, steel frame formwork provides a sturdy and rigid structure that can easily accommodate the placement of reinforcement bars. The steel frames are designed to securely hold the bars in place, preventing any movement or displacement during the concrete pouring process. This ensures that the reinforcement bars are properly positioned and aligned, which is crucial for the structural integrity of the concrete element. Secondly, steel frame formwork typically includes specially designed accessories and components that facilitate the placement of reinforcement bars. These accessories, such as steel bars holders, spacers, and connectors, are integrated into the formwork system to ensure that the bars are correctly spaced and supported. This allows for precise positioning of the reinforcement bars according to the specified design requirements. Furthermore, steel frame formwork often provides adjustable features that allow for easy customization of the reinforcement bar placement. These adjustable elements, such as movable brackets or adjustable connectors, enable the formwork system to accommodate varying bar sizes and configurations. This flexibility ensures that the reinforcement bars can be installed in the most optimal positions, considering factors such as load distribution and structural requirements. In addition to the technical aspects, steel frame formwork also offers advantages in terms of time and labor efficiency when handling reinforcement bars. The steel frames can be easily assembled and disassembled, allowing for quick and convenient installation of the reinforcement bars. This helps to reduce construction time and labor costs, making steel frame formwork a popular choice among contractors and builders. Overall, steel frame formwork provides a robust and versatile system for handling the placement of reinforcement bars. Its ability to securely hold and support the bars, along with its adjustable features and time-saving benefits, makes it an effective solution for ensuring proper reinforcement in concrete structures.

- Q: How does steel frame formwork handle the placement of reinforcement cages and mats within the concrete structure?

- Steel frame formwork provides a sturdy and reliable framework for the placement of reinforcement cages and mats within the concrete structure. The steel frames are designed to securely hold and support the reinforcement elements, ensuring proper alignment and positioning during the concrete pouring process. This formwork system allows for precise placement of reinforcement, minimizing the risk of displacement or misalignment, and ultimately enhancing the overall strength and durability of the concrete structure.

- Q: Are there any restrictions on the formwork height that can be achieved with steel frame formwork?

- The formwork height achievable with steel frame formwork is not limited. Steel frame formwork is renowned for its robustness and longevity, enabling it to sustain greater heights in comparison to alternative formwork systems. Nevertheless, the utmost attainable formwork height might be contingent upon diverse factors, encompassing the configuration of the steel frame system, the type of support structure employed, and the load-bearing capacity of the surrounding structure. To ascertain the suitable formwork height according to the particular project prerequisites and safety regulations, it is crucial to seek guidance from structural engineers and formwork manufacturers.

- Q: What are the different components of a steel frame formwork system?

- A steel frame formwork system is composed of multiple components that collaborate to offer support and structure during concrete construction processes. These components encompass: 1. Steel frames: The fundamental element of a steel frame formwork system is the steel frame itself. These frames are usually constructed from high-quality steel and are engineered to be sturdy, long-lasting, and capable of withstanding the weight and pressure exerted by the concrete. 2. Panels: Steel frame formwork systems also incorporate panels that are affixed to the steel frames. These panels are commonly made of plywood or metal and provide a seamless surface onto which the concrete can be poured. The panels are easily installed, removed, and replaced, resulting in a highly efficient and cost-effective system. 3. Wedges and clamps: Wedges and clamps are employed to secure the panels to the steel frames. Wedges are inserted between the panel and the frame to hold them in position, while clamps offer additional support and stability. These components ensure that the formwork system remains secure and taut throughout the concrete pouring and curing stages. 4. Adjustable props and supports: Adjustable props and supports are utilized in a steel frame formwork system to provide extra support and stability. These props and supports are easily modifiable and can be set at various heights to accommodate the desired formwork dimensions. 5. Accessories: A range of accessories is also included in a steel frame formwork system, such as corner brackets, alignment clamps, connectors, and anchor bolts. These accessories aid in achieving proper alignment and connection of the formwork components, resulting in a robust and dependable system. All in all, a steel frame formwork system presents a versatile and efficient solution for concrete construction projects. Its diverse components collaborate to offer a strong and reliable support structure, enabling the precise pouring and shaping of concrete to create desired structures.

Send your message to us

Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords