Fabric Formwork For Concrete

Fabric Formwork For Concrete Related Searches

Fabric Concrete Forms Fabric Formwork Formwork For Concrete Stairs Form Work Concrete Concrete Formwork System Concrete Boxing Formwork Advanced Concrete Formwork Concrete Pit Formwork Materials For Formwork Concrete Formwork Plywood Forming Concrete Types Of Formwork In Construction Flexible Plastic Concrete Forms Circle Concrete Forms Form Construction Radius Concrete Forms Foundation Formwork Off Form Concrete Gass Formwork Plywood Formwork Moving Formwork Striking Formwork Formwork Props Aluminum Concrete Wall Forms Plasticiser For Concrete Column Clamps Formwork Green Formwork Rough Formwork Formwork Installation Gliding FormworkFabric Formwork For Concrete Supplier & Manufacturer from China

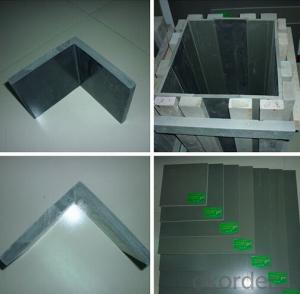

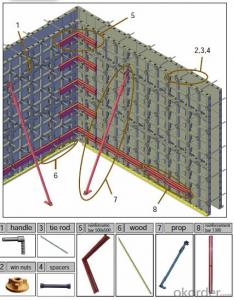

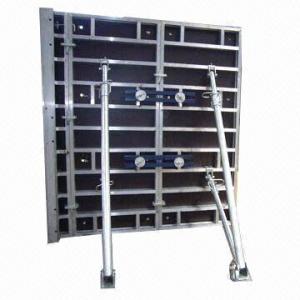

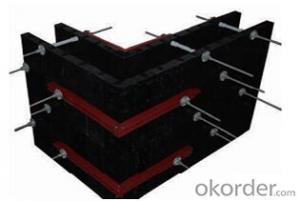

Fabric Formwork For Concrete is a versatile and innovative construction material that has gained popularity in recent years. This product is designed to provide a cost-effective and efficient solution for creating various shapes and structures in concrete construction projects. Its flexibility and adaptability make it an ideal choice for architects and contractors seeking to achieve unique and intricate designs with minimal effort.The application and usage scenarios of Fabric Formwork For Concrete are vast, ranging from residential and commercial buildings to infrastructure projects such as bridges, tunnels, and retaining walls. This product allows for the creation of complex and curved surfaces that would be difficult or impossible to achieve with traditional formwork methods. Its lightweight and easy-to-handle nature also makes it an attractive option for projects with limited access or space constraints. Additionally, Fabric Formwork For Concrete is environmentally friendly, as it can be reused multiple times, reducing waste and minimizing the overall environmental impact of construction projects.

Okorder.com is a leading wholesale supplier of Fabric Formwork For Concrete, boasting a large inventory of this innovative product. As a reliable source for construction materials, Okorder.com ensures that customers receive high-quality products at competitive prices. With a commitment to customer satisfaction and a focus on providing exceptional service, Okorder.com is the go-to destination for those in need of Fabric Formwork For Concrete for their construction projects.

Hot Products