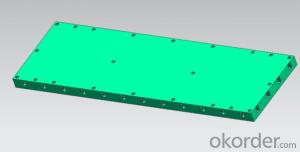

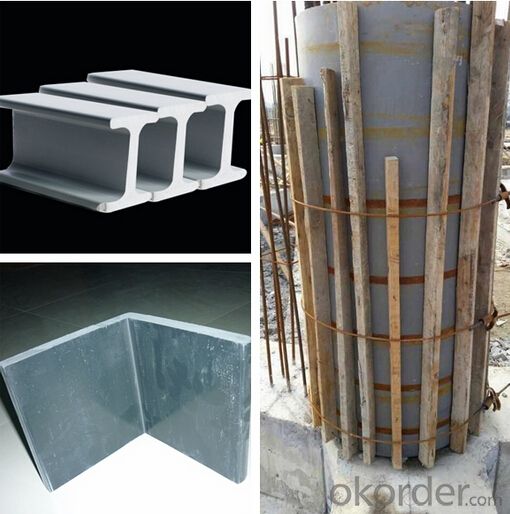

Long Using Plastic Formworks for Column

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Plastic PVC Foam Board Formworks Introduction

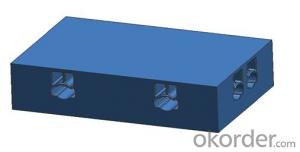

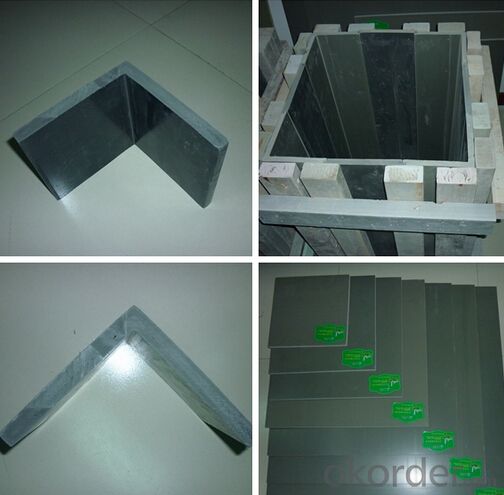

This kind of construction formwork can be special form like column and square.

They can be used in bridge, office building and roads construction.

Our products have characters such as energy conservation, environment-protection, and in low price. Another, turnovers can be up to 30 times, temperature adaptation range is wide. Plastic steel template can be any sizes so that it has wide adaptation.

easy installed and removed, sawed and drilled, and accessories complete.

save working hours more than 30% and increase efficiency more than 40%.

save construction template allocable cost over than 50%

Waterproof Plastic PVC Foam Board Formworks Feature

1. Life:turnover can be up to 40times

2. Tempreture condition:-20°C to 60°C

3. Feature:save 40%manhours and 50 %allocable cost

4. Convenient installation:be widely accepted by workers

5. Moldable size:size can be changed freely.

6. Resist compression:can support more than 5000 kilograms

7. Waterproof:100%

8. Useable widely used in building and construction

9. Energy saving,/environmental protection,/resource circulation

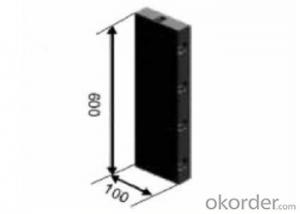

Waterproof Plastic PVC Foam Board Formworks Paramwter

Material: PVC | Structure: solid plate |

Cycle-index: 30 times above | Water content :0.3% |

Water thickness expansion rate: 0.1% | Static bending strength:21.9MPa |

Bending elastic modulus:1280MPa | Wear resistant surface(g/100r):0.08g/100r |

Condition after heating: no bubbles, no crack, no pitting | After heating the size change rate :0.20% |

Grip screws to board : 1470N | Grip screws to the edge of the board : 1070N |

Anti impact performance :14.1mm Impact toughness :64.8KJ/ m2 | High temperature repeated dimension change rate :0.12% |

Waterproof Plastic PVC Foam Board Formworks Specification

1, 15*915*1830(mm) 16.5Kg/pc±1Kg

2, 15*1220*1240(mm) 29Kg/pc±1Kg

3, Specifications can be customized

4, About 100M3 /T

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Personally feel that PVC sheet deformation has more reasons. The main reasons are as follows.Pvc plate deformation are: physical deformation and chemical deformation.1. Physical deformation, cause:High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems. Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the root causes.2. Chemical deformation: mainly the molecular structure of raw materials change.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- The reason why the use of the template is to use the template template is the accuracy of the template, that is, after the mold can be set to ensure that the finished product finished shape regular, flush. While the plastic film version is not damaged, the completion can achieve this requirement. But the crux of the problem is that the biggest weakness of the plastic film is too brittle. Those who have done the work know that when the demolition of the template, the workers removed the template directly down to throw. And this throw to lead to the plastic film version of the broken, it is very difficult to film in the film. This is also the reason why the plastic film from the interview more than 10 years can not always develop the root causes. And then plastic film board in the mold when it is very strenuous, must drill with a drill, or can not die, not convenient construction. This is also a plastic film version can not become a mainstream template and a fatal weakness. The third weakness is its flammability. Construction site of the steel connections are required welding, welding flowers gradually to the plastic film board, at least in its surface to form a deep pit (or even lead to fire), a direct impact on the finished product surface finish and flatness.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- To be honest, not very good. The Temporary use can be

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- The quality of the template is related to the quality of concrete engineering. The key lies in the accurate size, the assembly is firm, the patchwork is tight and the assembly and disassembly is convenient. Should be based on the structure of the form and characteristics of the appropriate form of template, in order to achieve good technical and economic results.

- Q: Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Should not be less than 160mm, and should not be less than the floor of the high 1/20; bottom reinforced parts of the wall thickness of not less than 200mm, and should not be less than the floor of the high 16/1. Hope to be helpful to you.

Send your message to us

Long Using Plastic Formworks for Column

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords