Vertical Mix-flow Turbine Pump(API610 VS6)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

Vertical mixed-flow Turbine Pump for high capacity

VTM Series is a sigle stage pump with mixed-flow semi-open or enclosed type impeller

Hydraulic design of the pump bowl assembly

Wide range of hydraulic conditions to meet virtually every pumping service with optimum efficiency

Designed for high high capacity, medium to high head services

2. Application

Cooling water

Seawater and raw water intake

Industrial process pumps

Utility circulating water

Condenser circulating water pumps

Ash sluice

Fire-fighting

3. Technical Data

Capacities to 40000m3/h (180,000GPM)

Heads to 60m (200ft)

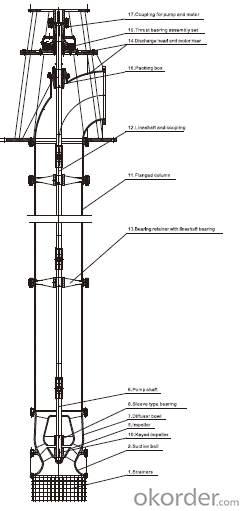

4. Pump Structure

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: Why does the pump decay when connected in parallel?

- When two pumps are connected in parallel, the flow rate is less than two of the rated flow of the pump. That is because of the loss of the pipeline and the incomplete sealing of the one-way valve (backflow) and the maximum capacity limit of the pipeline. The solution is to increase the diameter of the supervisor, check whether the one-way valve is completely sealed, whether the inlet and outlet pipe is blocked or not, and reasonably reduce the elbow and the valve.

- Q: what is a submersible well pump?

- It is exactly what it sounds like-a water pump that you put in your well under water. It pumps the water into the house directly from the well, and uses the water as a coolant. Usually they are about 18-24 inches long, about 3-5 inches around, and weight about 40 pounds; and cost a small fortune (if you ask me anyway). Depending upon who you ask they are also the most efficient way to get the water from your well to the house, and do not need anywhere near as much servicing as above ground or in-house pump. Ask your local pump dealer which pump is best for you and the needs of your household-they should be able to give you several to choose from.

- Q: I think the water pump on my 40 hp mercury outboard 2 stroke is not working, the hole witch usually pours out all the water that was used to cool the engine does not pour any water at all. Is this a problem with the water pump? If not what?

- Check the water intake is not blocked. Then the water impellor. Then lastly check the water tell tail outlet hole is not blocked/obstructed.

- Q: i hear water swirl in my dash board when i take off and when i reverse, i heard its the water pump pushing water through the heater core, but how can i fix it.?

- Sounds like you have air in your engine cooling system. Newer cars are notorious for trapping air pockets in the engine when the coolant is changed. Take the car to an auto repair shop and have them bleed the air out of the system.

- Q: we live in the country in the warm months and have a portable pump that takes water from a 15 foot deep well. It feeds water to a toilet and a hot water tank mostly and a sink and shower and washer. We put the pump outside the bathroom and need to know how to start it, thanks!

- There are so many different kinds, brands, types of pumps available for the purpose you're stating that it's not even funny, but for the purposes of this forum we will have to assume that it's a standard shallow well jet pump that draws water up from the ground and pushes it out the other side of the pump. Just in case you've never heard of the FOOT valve, it's what we've always called a check valve. It goes in the line coming up from the ground to stop the flow of water going back down the pipe once it's up and past the valve. That's what makes the pump keep it's prime, which is what you're actually asking, how to prime a pump. You'll need to open a pipe going into the top of the pump and pour enough water into it to make sure it's got plenty in the front casing. The pump shouldn't run dry. Once you're sure there's water in the casing then plug in or turn on the pump motor and continue to pour water into the pipe till it starts squirting out the top profusely. Then you can cap up the pipe and it should pump. If need be you can repeat till it catches.

- Q: I think its the water pump, I fill the coolant with water everyday and it is empty once I make it to my destination.

- Call the shop where you are going to have the work done to get the cost as it varies by area and shop. You really should not be driving it if it's leaking that bad: You stand a chance of warping the head.

- Q: We have 2 1995 E320's that are heating up way too high when running. One has been diagnosed at the repair shop for a malfunctioning fan clutch. They also said that as the car was running hot the water pump and thermostat should also be replaced (??) The water pump is 5.5 hours of labor and I cannot afford it right now. I was wondering how hard to replace it myself. Thanks

- 95 Mercedes E320

- Q: I have a 1978 El Camino V8 305. My power steering has been going out on me, and since then my belt has been squeaking usually when it first starts up. This morning when I got to work, smoke was bellowing from under my hood. Im trying to troubleshoot. Is it possible that my power steering pump damaged the belt enough that the water pump went out?

- If the power steering pump was dragging, you probably lost the belt, so the water pump was not working and the engine overheated. Water pump is probably OK. Replace the belt and fix or replace the power steering pump.

- Q: i have a significant stream of water running out of the coolant return side of the engine under the coolant pipe on a 1997 caravan i will lose a gallon and then it stops until the engine heats up and of course more comes out with expansion

- You will have to remove the AC compressor, all of the drive belts, alternator bracket, power steering pump and bracket, motor mount, timing cover, and the timing belt. This job calls for 4.3 hours and I was able to do one in about 3. If you really want to attempt this yourself, let me know and I will give you detailed step by step instructions to do it, right down to the timing marks and what size each bolt is. If you have never done a water pump/timing belt on any car before, I strongly recommend you don't attempt this repair yourself. The 3.0 really isn't a bad one to do, if you have the tools and some mechanical knowledge and ability.

- Q: i have a 1996 infiniti i30t and its leaking from underneath the car so i took it in to get it diagnosed and they said i need a new water pump and they are trying to charge me 500 dollers and if i need a new timing belt i have to pay a 1000 dollers. is there a cheaper way i can fix my car. it started to over heat today and this sucks cause its my only car my parents wont buy me a new car so im stuck with this stupid old car and i have to pay for it they wont help me. can someone help me?

- an air bubble and its probable a stable theory to alter the thermostat once you regulate a water pump u would desire to alter the thermostat just to be risk-free that and it in all risk hasent been replaced for a protracted time so chang it i artwork in a keep. yet you're your guy or woman individual so do what you think of you will desire to ok

Send your message to us

Vertical Mix-flow Turbine Pump(API610 VS6)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords