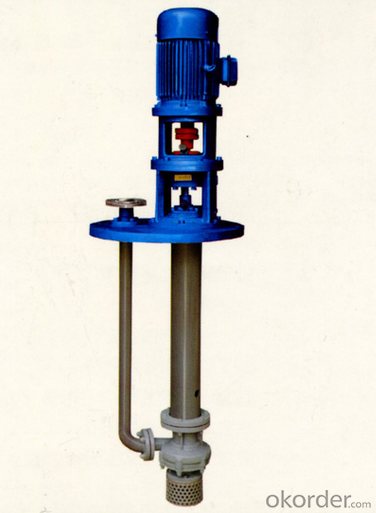

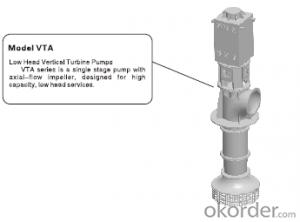

Vertical Cantilever/Submerged Pump(API610 VS4)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

According to API610 VS4 type

Linshaft is reliable

Rotor assembly is adjustable in the axially direction, multi-supported, running reliable

Slide bearing is out lubricated

Double volute casing for sizes more than 80mm to balance the radically forces.

2. Application

Power station

Petro chemical industry

Water treatment

Steel factory

Pulp & paper

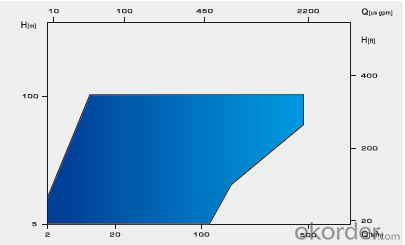

3. Technical Data

Capacity: 2~500m3/h

Head: 5~100m

Temperature: -20~120℃

4. Performance Curve

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: The truck is a 1982 Ford pickup F100. We didn't realize it was an F100 at the time and we put the F150 water pump on it. The water pump fits perfectly, but is this going to mess up the engine at all?

- No it won't mess up the engine as long as there are aren't any leaks meaning a new gasket is used, the belt is adjusted correctly and is aligned, and the thermostat is replaced using the correct temperature item. Any good parts store employee can sell you the correct thermostat.

- Q: We bought a second hand Rover 75, three months later head gasket blew. This was replaced but blew again due to original wet liners. A reconditioned engine was then put in but head gasket blew again due to original water pump. I am not trying to ascertain blame i would just like to know which is accurate as car seller is saying fault of mechanic as should have changed wet liners and water pump and mechanic is saying it is not common practice to change this parts when you replace a head gasket or engine. Thanks for any clarification, especially if you are a mechanic yourself.

- It seems excessive to have to remove the engine to replace a head gasket. But I typically work on American cars, and I've seen the inside of an Altima, it is quite cramped. If I were you, I'd search google for replace head gasket procedure nissan altima and see what it comes back with.

- Q: what is a submersible well pump?

- lets break it down... submersible- able to be put underwater... well- deep hole that water comes from... pump- sucks the water...

- Q: Im looking at putting a little cabin on my property for hunting. i have a 200 gallon under ground water tank for fresh water. I'm needing a pump to run water into the cabin for a sink toilet and possibly a shower. does anyone know what style pump i will need so that it does not constantly build up pressure when not in use that way i don't burn it up.

- The way wells work is there's a pump at the bottom. It pumps water into a holding tank that has a diaphragm separating water from an air charge. There's also a pressure sensor switch that kicks the pump on when the pressure in the water tank drops below 40 PSI and shuts it off when it reaches 60 PSI. Well water systems don't just run the pump constantly, or they would burn up. What you want to do is use your storage tank as a source. Pump that into a smaller holding tank from a well water system so that when you run the water you run it from the pressure in the holding tank. When the pressure is low enough the main tank pump will pump up the pressure in the holding tank back to 60 PSI and shut off again. It's well worth it to make sure you don't have leaks. Otherwise your main tank will end up empty and the pump will run on and on. Which is another thing you have to watch for. You can install a float level switch so that if the water in the main tank drops below a certain level it shuts the pump off. AND you can also have it switch a warning light on so you know when the big tank is empty. Hope this helps. '')

- Q: I've searched the net but cannot find exactly what I'm looking for and hoping someone out there can steer me in the right direction! Maybe I'm not looking in the right place....or do I have to fabricate my own? I'm up for the challenge!1) Trying to source a water pump that I'm going to power by HAND or a BICYCLE. 2) My choice of pump to give a continuous stream of water (very important) is a rotary (centrifugal) type or is there something else capable of a continuous output?3) This will NOT BE USED for potable water. SPECS:a) lightweight but durable, the smaller, the better. b) low RPM, high volume output and capable of producing/handling pressure. c) self-primingd) able to handle some small particulates in the water as I am using rain water. (from outside, NOT filtered, so the following may be present: bugs, dust, etc...) Thank you, in advance, for your help and would be nice to thank the individual(s) for a unique answer to my request at a later date so let me know you're preferred method of contact!

- Those are widely used where hand or bicycle or animal power is common. It meets all your criteria except pressure. Depending on how much pressure you want/need a stand pipe or elevated tank might meet that requirement. If pressure is necessary, then go with a Double Acting Piston Pump and filter the suction. I recommend a Graded Sand Bed over the suction. I designed public water supply pumping stations drawing from rivers for years. Filtering the suction is no big deal.

- Q: I was vacuuming up water from my basement I assumed was from the rain, suddenly water started spraying out of a blue pump at the base of my furnace, don't know what the pump does or why its spraying but its making an awful mess.

- Blue pump, usually found on the floor near the furnace (sometimes mounted where plenum meets the furnace frame) is a condensate pump. One of the products of combustion is water. This water is drained from the ventor motor (a motor which runs and sets a artificial draft inside the combustion chamber) to a drain nearby or a electric pump which then pumps the water over a longer distance to a remote drain. If the pump's discharge outlet gets plugged from dirt the result is usually the mess you see. Remove the cover plate of the pump housing, clean it out and run a wire with a small rag attached as a snake through the tube to drain. There is usually some type of float switch inside the pump housing so make sure it is free to move. Check for operation by pouring some tap water in it and move the float switch to on (up) One final note and this is very important. If the pump or tube to drain is filled up with a crud that resembles paste, call your local trusted HVAC tech for furnace service. This condition can be an early sign of heat exchanger failure and is a major safety concern for your family

- Q: If a person took a water pump and attached to a hose and ended up with (random numbers) 15 gpm and 30 psi at the end of the hose, what would happen if you put an exact same pump right next to it and hooked the two pumps together with a quot;Yfitting to a single hose? Would both the gpm and psi be doubled, or neither, or just one? What would happen?

- Any discharge piping system down stream of a pump (in this case a hose) will have a pressure drop that varies with flow. You can develop a curve of this pressure where flow rate is plotted against pressure drop. Any centrifugal pump will have a performance curve. The lower the discharge head (pressure) the more the pump will pump. The higher the head the less the pump will pump. Assuming these are centrifugal pumps then their performance will balance with the system pressure drop curve to seek a point on each pump's operating curve that matches the overall system pressure drop curve. In other words the pressure will go up some and the flow rate will also go up some but neither will double.

- Q: Where can I get a solar powered water pump for a sprinker? I want the pump to pull water out of a river next to my yard and water my garden and lawn.

- Solar catalog. You will need a whole system, to collect the solar energy in the day and use battery's at night to run the pump,as you would not want to run the sprinkler in the sun light.Also think of elevator storage of the water. the head pressure will help the pump. If you have access to a river think hydro power,also, for cloudy days. Water turbines to generate electric, place under the surface. Get thinking man.

- Q: Why is water pumping cool water is normal, but when pumping hot water pressure and flow are very small?

- There may be: first, the water temperature is too high, the impeller damage! But this may not be very likely! Second, but also the water temperature is too high, but may be too high water temperature will be hot water pipe deflated, resulting in no water. Third, it is possible to buy fake and shoddy products!!! Another important problem is that you didn't tell me what kind of pump it was! What forms of work do you have?

- Q: Hello,I have a Kia Spectra, 4 doors, automatic, 1.8, 2002, 64000 miles, and the alternator belt just broke. It seems that there is a chance that the water pump was lost on the process.I looked on line and to buy from the dealership, these pieces together would cost me around $70.What would it be a fair price for the service? (thinking that I was unlucky enough to lose the water pump?How do I know if my water pump is good and they are only changing it to make me spend more money???I am a girl (foreign student), and don't understand of car, or know any repair shop that could take care of that...Thanks!!!

- Changing a water pump is usually costly because it can be time consuming. Having the belt on your car break should not cause your water pump to go out, but having your water pump go out could cause your belt to break. A way to check your water pump would be to make sure that the pully spins freely but that it does not wobble or have extra play. Another sign that your water pump is going bad is when it begins to leak. This means that the seals are bad, and that water can now get into the bearings causing them to degrade and eventually seize up.

Send your message to us

Vertical Cantilever/Submerged Pump(API610 VS4)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords