Vertical Axial/Mixed Flow Propeller Pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vertical Axial/Mixed Flow Propeller Pump Introduction

QZ series axial-flow pumps are modern products successfully designed through adopting foreign modern technology. The new pumps’ capacity are 20% larger than the old ones. The efficiency is 3%-5% higher than the old ones. QZ series pump with adjustable impellers has the advantages of large capacity, broad head, high efficiency, wide application and so on. Pump station is small in scale, the construction is simple and the investment is greatly decreased. This can save 30%-40% for the building cost. It is easy to install,maintain and repair this kind of pump. Low noise,long life.

Vertical Axial/Mixed Flow Propeller Pump Parameter

QZ series axial-flow pump is applicable for water supply in cities, diversion works, sewage drainage system, sewage disposal project.

Propeller Pump Technical Data:

Flow rate: up to 20 m³/h

Head: up to 20 m

Speed: max rpm

Temperature: max °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

Material: nodular iron, stainless steel, duplex

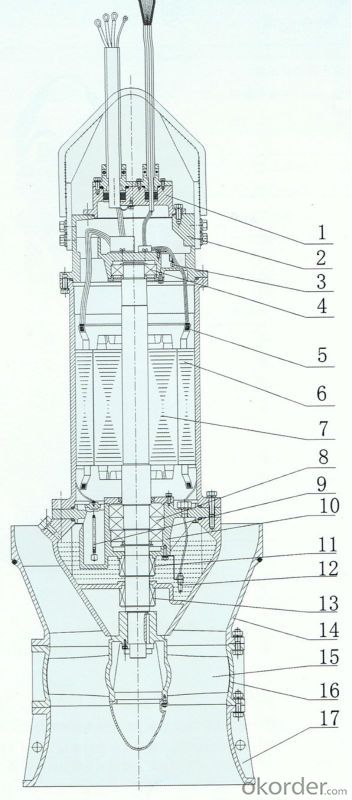

Vertical Axial/Mixed Flow Propeller Pump Structure

NO. | Name | Material | NO. | Name | Material |

1 | Terminal Cover | FC250 | 10 | Gland Cover | FC250 |

2 | Gland Cover | FC250 | 11 | Upper Mech Seal | Graphite/Sic |

3 | Leakage Alarm | Standar | 12 | Electrode Probe | standar |

4 | Bearing | Heavy duty | 13 | Down Mech Seal | Sic/Sic |

5 | Heat Protector | standar | 14 | Guide Vane | FC250 |

6 | Stator | FC250 | 15 | Propeller | SUS304 |

7 | Rotor | SUS420 | 16 | Casing | FC250 |

8 | Bearing | Heavy duty | 17 | Suction Horn | FC250 |

9 | Leakage Alarm | Standard |

- Q: does any one know were a water pump is located on a 97 nissan altima? and where can i get a good deal on one?

- [with the car jacked up] Follow the rubber pipes coming out of the radiator. You should eventually find a metal device that is connected to your serpentine belt (fan belt). This device is your water pump. The purpose of the pump is to run cool water through the engine to cool it off. It needs to be replaced if it is making noise or if your car heats up too much. hope this helps! :)

- Q: My dad bought a boat this winter and when we got it we watched the guy winterize it. He was doing this white it was running on muffs. We got the boat to run today (on muffs) but no water was coming out the pee hole. This is the first boat we have owned. We are rookies. We also don't to take it to a dealer. Is there anything we're doing wrong? I don't know for sure what year the motor is i think a 1900 something. It is 90 horse.

- Don't panic yet. Sometimes the tell-tale is clogged. Do you get water out the exhaust? If so it is pumping. Try putting a utility air nozzle to the tell-tale and giving it a puff.

- Q: How do I change the water pump on a 2003 PT Cruiser. What do you do with the timing belt and gears?

- if you have 100,000 miles on it, and haven't changed the timing belt, CHANGE IT NOW. Recommended change at 100,000 miles. Mine broke at 104,000, towing was $125, and then cost of repairs. Also recommend changing seals on xmission at same time.

- Q: A Pump is direct driven by a 25 HP 900 rpm electric motor at rated load. In order to to double the quanitity of water delivered, it would be necessary to substitute a motor rated at____HP at____rpm. ans. 200 and 1800. not sure how they came up with this answer...whats the equation???

- N = (95 H.C)/D Where N = rev/min D = diameter of impeller over blade tips in metres H = total head in metres C = constant. C depends on the shape of the pump and normally lies between 1.05 and 1.2 Later edit. I'm not sure if you are aware of it but each impeller has it's own characteristic performance curve.

- Q: where would I be able to find information on how to change out a water pump for that specific type of vehicle and year, as well I had got a stain on the body from road work it seems to be cement how could I take spots out without damaging the body's paint? What are my options thanks...

- why would you like to replace the water pump? seems to me the factory warranty of 3 years 36,000 miles might apply unless you're over on mileage. if you can email me, i will get you the procedure.

- Q: need step by step on how to change water pump

- The water pump is ran by a belt on the back of the cylinder head There is a belt tensioner that is released by a 3 /8 ratchet . Once you get the belt off take off the pulley and next you will have to have a special tool that inserts into the water pump socket and turn it counter clockwise to release the pump .When you put it back together make sure you put a little grease on the O-ring so you don't damage it . They are fairly simple if you have the tool they should have one at any good parts store . Good luck .

- Q: My car randomly decided to dump fluids the other day. Now, the engine overheats after 5 minutes of driving it and the check engine light comes on. I put more coolant in it and noticed it began to drip underneath the car. I'm hoping it's a leak but being my car is 10 years old and I've never replaced either the water pump or the head gasket I figure it's about due time unfortunately. About how much would this cost me to have done at the garage?

- The waterpump should run you around !$150 or less at most garages, -- about $45 maybe- if you do it yourself! The headgasket will probably cost you around 3-5 hundred depending on how much labor charge is! As it is possible that the head is warped and may need re-surcfaced to make it flat again --- and of course cost is going to depend on how much damage was done, -determined by how hot it got before you shut it down! The head gasket etc. shouldn't run much more htan $125-150 Now if it runs ok,-- and doesn't overheat when the radiator is full of water, -- even after warming up and driving on road for a few ninutes, -- (if leak fairly small - it will take some time to get down low enough to cause heat buildup)! I'd say 5 miles on highway would prove it is not warped head!! -- Just keep eye on temp and shut down if it starts getting close to overheat--- to avoid increasing damage, - if head gasket out! In yard, you can get pretty good idea, by just filling up raidator, and leaving cap off with engine running-- after it has idled for a few minutes, (and you have topped it up a couple times to make sure it is full of water, -- if gasket leaking it will blow continueous bubbles, -- after the thermostat opens, a little water will rise and run over (expansion of water) ). -- ****However it should not contionue blowing any continueaous bubbles--- (continued large quantities of bubbles indicates compression being blown into water jacket from bad headgsket!) ...A small bubble now and then is negligeable, as a bubble or two may still be trapped from when water level was down! You will know when thermostat opens, as there will be moving water obvious through filler neck of radiator, and the upper hose will become hot going into radiator! It is also possible that you may see oil on water if headgasket leaking, as well as water in oil-- which would be sort fo fuzzy yellowish looking junk on dipstick, and oil fill cap!

- Q: I am leaking antifreeze, but only when the car is sitting after it has been running for a while, and its quite frustrating..it's coming around where the hoses are, I just got the thermostat/thermostat housing replaced, and also the heater hose and it seems to be coming from the same general area AS those...My car doesn't leak all the time it seems, so I'm not sure what this could mean. It has not over heated, my ac isn't also working at all.I have taken it back to the mechanic two times in the last 2 days and they cannot determine it's having a leak or not..which is quite ridiculous!! It seems to them that they think I'm crazy or something, I just don't like to see antifreeze underneath my car, I mean who does? Does this sound like a water pump? Where exactly is the waterpump located?

- The water pump i believe is a factor of the cooling equipment. If the water pump became undesirable then your temperature gauge would have a bigger than prevalent examining. i'm no longer a mechanic or something yet my maximum suitable wager would be that is something different than the water pump occurring at the same time with your automobile. stable success!

- Q: What's the submersible pump?

- Zhengzhou sea diving pump. Deep well submersible pump is a fountain, drinking water transportation, irrigation, hot springs, high-rise transport facilities, etc., deep well submersible pump excellent performance, so widely used in various fields.

- Q: i got that special socket but everytime i try to loosen the pump going clockwise i can not get the pump to come loose the socket just slips off any suggestions these is a northstar engine

- The tool you need is the kent moore design one. it has a bracket that bolts on and helps hold that socket that you call it snug against the pump..one other thing look at the new pump to determine the direction it loosens because i do not remember,also we have only one tool and its worked on all northstar engines so far

Send your message to us

Vertical Axial/Mixed Flow Propeller Pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords