Boat Propeller Parts

Boat Propeller Parts Related Searches

Boat Propeller Cover Acme Boat Propellers High Performance Boat Props Bass Boat Props For Sale Neptune Pump Parts Boat Prop Lock Ship Propeler Fisher Control Valve Parts Outboard Propeller Repair Boat Prop Guard Air Duct Parts Tub Spout Replacement Parts Large Ship Propeller For Sale Repair Parts Inboard Boat Propeller Calculator Gas Stove Parts Schwing Parts Replacement Plumbing Parts Whirlpool Appliances Parts Crane Spare Parts Concord Elevator Parts Thread Parts Schindler Elevator Parts Hauer Elevator Parts Lev Elevator Parts Outdoor Spigot Parts Construction Props Perkins Engine Parts Heating And Air Conditioning Parts Scissor Lift PartsBoat Propeller Parts Supplier & Manufacturer from China

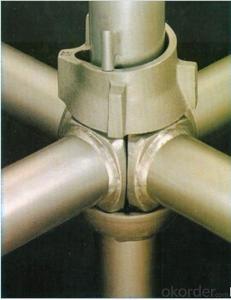

Boat Propeller Parts are essential components that contribute to the efficient functioning of marine vessels. These parts include propellers, shafts, hubs, and various other accessories that work together to propel boats through water. The proper selection and installation of these parts are crucial for achieving optimal performance and ensuring the safety of the vessel and its occupants.Boat Propeller Parts are widely used in various applications, such as recreational boating, commercial shipping, and naval operations. They are designed to cater to different types of boats, including sailboats, motorboats, and yachts. The usage scenarios for these parts range from leisurely cruising to high-speed racing, and from shallow waters to deep-sea exploration. The choice of Boat Propeller Parts depends on factors like boat size, engine power, and intended use, which ultimately impact the vessel's speed, maneuverability, and fuel efficiency.

Okorder.com is a reputable wholesale supplier of Boat Propeller Parts, boasting a vast inventory that caters to the diverse needs of the marine industry. The company offers a comprehensive range of high-quality products, ensuring that customers can find the right parts for their specific requirements. By partnering with Okorder.com, customers can benefit from competitive prices, reliable service, and a commitment to excellence in the supply of Boat Propeller Parts.

Hot Products