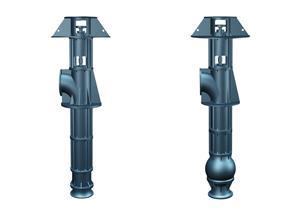

ZLB Vertical Axial/mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Summary

Z(H)LB vertical axial-(mixed)-flow pump is a new general-eration product successfully developed by this Company by means of introducing the advanced foreign and domestic know-how and meticulous designing on the basis of the requirements from users and the conditions of use. This series product uses the latest excellent hydraulic model, wide range of high efficacy, stable performance and good vapor erosion resistance; the impeller is precisely cast with a wax mould, a smooth and unimpeded surfac e, identical accuracy of the cast dimension to that in design, greatly reduced hydraulic friction loss and shocking loss, a better balance of impeller, a higher efficiency than that of the common impellers by 3-5%.

Flow:800~200000m /h

Head:1~30.6m

Power:18.5~7000kW

Voltage: 355kW 6kV 10kV

Frequency:50Hz

Extensively used for hydraulic projects, farm-land irrigation, industrial water transportation, water supply and drainage of cities and water allocation engineering.

Suitable for pumping pure water or other liquids of the phy-sical chemical natures similar to those of pure water.

Medium temperature: <50

Medium density: <1.05 x 10 kg/m

PH value of medium:between 5~11

ZLB(Q),HLB(Q) series products are all of a vertical structure and fitted with a vertical motor, With the impeller there are fixed, semi-adjustable and fully-adjustable type. The fixed type means

both impeller and hub are cast integrally and the impeller angle is unadjustable; the semi-adjustable type means the impeller can be turned to the desired angle by loosening the fixing screw on it in case the working conditions need to be changed, then fix all the impellers again; Z(H)LQ is the fully-adjustable type, that means the impeller angle can be adjusted through a mechanical or hydraulic adjustor with or without stopping.

Vertical axial-(mixed)-flow pump consists of the pump casing and the actuating part. The pump casing generally includes water inlet pipe, impeller, guide vane, pump shaft, elbow, middle pipe, sealing unit and clutch. For both middle and small pumps, a water inlet horn is used as the water inlet pipe while, for the large one, a toggle or bell water inlet passage is used, poured with concrete and fitted with imported basic parts. The adjustable impelle r is formed with blade(stainless steel or copper alloy, in general), hub, water guide cone. For the middle and small pumps, both impeller and pump shaft are connected with flat pin and nut whi le, for the large and fully adjustable ones, a flange is used to connect both hub and main shaft. The pump s guide bearing is a rubber one and can be lubricated with going-through water or additional pure water. When lubricated with the going-through water, it has to be done to supply water for the rubber bearing on the upper side via a water-led pipe and do not stop until water comes out of

the pump normally.

Both middle and small pumps are directly actuated by a vertical motor, the motor is mounted on the motor seat and connected wi th the actuating shaft via an elastic cluth. Inside of the motor seat there are radial and thrust bearings, lubricated with engine oil or grease; for the one of a bigger power there is a water cooling mezzanine. Large pump is fitted with a large vertical motor, directly mounted on the motor s basic beam, and both motor shaft flange and pump shaft flange (hinged hole) are linked with bolt. The axial force of the pump is borne by the thrust bearing of the large vertical motor.

The pump moves clockwise viewing from the motor

- Q: I had a re-manufactured water pump installed and after 14 months I started smelling my radiator occasionally. Never suspected the pump since my original pump lasted 60,000 miles and was still fine when they replaced it feigning quot;it is customary to replace water pump with timing beltwhen in actuality my Hyundai Elantra just needs the pump checked every 60,000 miles. The re-manufactured water pump was diagnosed leaking for sure after 20 months. Anyway I believe the leaking pump which didn't get discovered for at least 4 to 6 months caused the early demise of my radiator. Does that make sense?Thanks,Mitzi

- i strongly disagree. a leaky pump, loosing fluid, replaced by air via a recovery system, will create excess water jacket pressures. ergo, the radiator. even if it has air trapped in it. that excessive pressure, if the rad is marginal/old, can cause rad leaks. any seasoned mechanic out there has experienced a vehicle that had air in it, and be so hot as to charge the system. on some, you can actually here them go bang as water/coolant, flows into a part of the systems that has just air. that sends pressure shock waves through out the system. i've experience some so hot, they won't shut off. dieseling per say. ---------- EDIT, Michael sir. i'm an ex fighter jet hydraulic/pneumatic tech USAF. 40 yr auto mechanic. 5 yrs on Harley's (iron blocks). been dealing with the use of compressed fluids and gas for some time now. ex boeing employee on the 747 as well. i just don't ahve all that in my profile. mostly, i just let facts speak for themselves. weather or not an OP see's that is up to them. --------- pressure can built up faster than it can be bleed off in *some* cases. especially if it's a slow leak. those were generic statements. meaning, they are a possibility. not out of the realm of possibility, and would be far from the first time it ever happened, that a bad pump can cause other parts of the coolant system to malfunction. i've seen marginal rads, hoses, and even heater cores go as a result of over pressureazation of the water jacket. but i meant no disrespect here. i will delete my seasoned mechanic remark. simply stating i have seen/experienced, in the shop, over the years, many instances like what i stated. it's not impossible!!! i'll delete all this crap too if you delete your remark. how bout it? friends?

- Q: How do I replace the water pump on a 1996 Mercury 200 hp outboard engine? I have the parts, but want to make sure I replace it correctly. Thanks!

- Save yourself a lot of time and trouble and take it to a certified Mecury mechanic.

- Q: 1.5KW water pump caliber is 40, what is the flow rate?

- General 40 caliber flow is 6.3 cubic meters, two pole motor lift about 32 meters.The so-called flow, refers to the unit of time through the closed pipeline or open channel effective cross-section of the fluid volume, also known as instantaneous flow. When the volume of fluid is expressed in volume, it is called volume flow. When the mass of fluid is expressed in mass, it is called mass flow.

- Q: The plumber has disappeared on us with 99% of the job done. Our new basement remodel has baseboard heating installed, a water pump attached to the furnace/boiler, but no heat downstairs because their is no thermostat. I haven't checked to see if he did any wiring. (Wouldn't that be an electrician's job?) I've ordered a wireless thermostat kit, and I'm assuming installation instructions for the base are included, but it hasn't arrived yet. What should I do to get that pump pumping hot water to keep us nice and cozy?

- That part in the picture is a high limit control with manual reset. It has nothing to do with the pump. You will need more than a thermostat to control the added pump. When you have more than one pump the system is zoned .You need a switching relay panel (Taco SR502) that not only turns on the pump , but also the burner. There is a lot to know here and it's best left to a heating contractor.

- Q: What is the 10KV pump unit?

- As the name suggests, the water pump unit is a number of pumps, and 10kV is the voltage level. According to the voltage level, what you call a water pump should be a pump with relatively large power

- Q: Hello, i have a 1987 volkswagen cabriolet that i purchased earlier this year. So far its been a pain in the butt. Recently i noticed it overheats real quick, but it didnt use to. then i noticed the coolant/antifreeze was being used up like no other! I discovered, after being parked at work, that it was leaking. it leaks basically anything i put in there now!! it leaks from the water pump housing,.,.... at least thats what the internet said it was.. its leaking from the end of the hose that connects to the engine... (the hose that comes from the coolant reservoir.) What do i do? I dont feel any cracks? does this part crack? is it an o-ring or somehting? how can i fix it? what happens if i dont? I am really absolutely NOTHING ABOUT CARS. Please help!!

- Water Pump Housing

- Q: honda acord water pump 1988

- hello Purchase a how to book, because part of the water pump sits behind the timing belt cover.Hope this was some help.

- Q: What is the difference between a low pressure pump and a high pressure pump?

- High pressure pump head, large power! High pressure pump, low pressure pump has no strict limit

- Q: I don't want to have to rent or purchase a electric pump to pump the water out of my pool so are there other ways to get the water out besides the obvious (a bucket and alot of people). I am really tight on money so purchasing a device to do the work isn't a real option but I really need to drain the pool without damaging it.

- You can do a back wash, which will drain it.

- Q: I am new to saltwater tank, and i what to add a sump to my tank, but I don't know what to add to it. what water pump? do i add the filter to the sump or does the filter stay in the tank.

- you do no longer use siphons to flow water to the sump, you employ an overflow and pipes. the point of having the overflow in a tank with a sump is that the pass between the two tanks would be even. while the water is pumped returned to the tank and reaches a definite point that water will then pass returned to the sump. If the capability will fail then the pump will end working, so no water would be moved returned into the tank, no water will overflow returned. the priority with 2 pumps would be that no 2 pumps are comparable. One pump is 2 hundred gallons consistent with hour, the different is 199, next one is 195 regardless of being from an identical authentic line and type. So in case you have a 2 hundred and 199 GPH you will finally end up with the two the tank or the sump spilling after some hours.

Send your message to us

ZLB Vertical Axial/mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords