16 Gauge Stainless Steel Sheet

16 Gauge Stainless Steel Sheet Related Searches

16 Gauge Sheet Steel 16g Stainless Steel Sheet 16 Gauge Stainless Steel 16 Gauge Stainless Steel Wire Stainless Steel 16 Gauge Wire 20 Gauge Stainless Steel Sheet Stainless Steel 20 Gauge Sheet 16g Stainless Steel Wire 16 Gage Sheet Metal 316 Stainless Steel Sheet 16ga Stainless Steel Thickness 14 Gauge Aluminum Sheet 18 Gauge Aluminum Sheet 1 8 Stainless Steel Sheet Sheet Of Stainless Steel 3 16 Stainless Steel 20 Gauge Aluminum Sheet 18 Gauge Galvanized Sheet Metal Black Stainless Steel Sheet 12 Gauge Stainless Steel 1/8 Stainless Steel Sheet 19 Gauge Sheet Metal Thin Stainless Steel Sheets 18 Gauge Stainless Steel 4 X 8 Sheet Of Stainless Steel 24 Gauge Galvanized Sheet Metal Stainless Steel Sheeting Stainless Steel Gauge 30 Gauge Sheet Metal 4x8 Stainless Steel Sheet16 Gauge Stainless Steel Sheet Supplier & Manufacturer from China

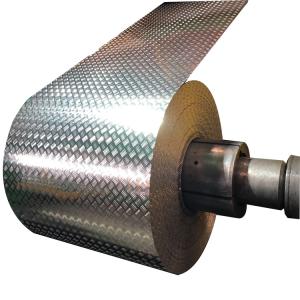

16 Gauge Stainless Steel Sheet is a popular choice among various industries due to its durability, corrosion resistance, and aesthetic appeal. Made from high-quality stainless steel, this product is known for its strength and versatility, making it suitable for a wide range of applications. Its thickness of 16 gauge offers a balance between rigidity and flexibility, allowing it to be used in both structural and decorative purposes.The 16 Gauge Stainless Steel Sheet is widely used in numerous industries, such as construction, automotive, aerospace, and food processing. It is particularly favored for its ability to withstand harsh environments and maintain its appearance over time. This product can be found in applications such as kitchen countertops, architectural facades, and industrial equipment, where its resistance to rust and ease of cleaning are highly valued. Additionally, its non-magnetic properties make it an ideal choice for environments where magnetic interference is a concern.

Okorder.com is a leading wholesale supplier of 16 Gauge Stainless Steel Sheet, offering a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the stainless steel sheets they provide meet the highest industry standards. Their extensive inventory allows them to quickly fulfill orders, making them a reliable choice for businesses looking to source this product in bulk. By partnering with Okorder.com, customers can expect to receive top-quality 16 Gauge Stainless Steel Sheet at competitive prices, along with excellent customer service and support.

Hot Products