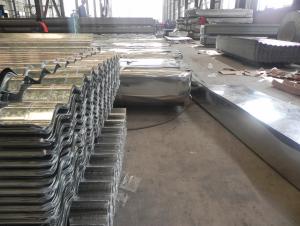

GAVANIZED STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GAVANIZED STEEL mesh is made of hot-dip zinc coated steel sheet,

It is used to be the material of untake out formwork for concret, widely used as plaster backing on ceilings, walls and stud partitions. Rib Lath is also ideal for refurbishing damaged or aged masonry walls when a key for rendering is not certain due to disintegration or softening of the wall face.

Material:Hot-dipped galvanized sheet

Application:

Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

Construction formwork mesh is widely used in tunnels,bridges and valve system and so on to make the process of construction much more fast and stable.

ZINC COATING: G50 WEIGHT: 4.6KG/SHEET

- Q: Can steel sheets be used for water-resistant applications?

- Yes, steel sheets can be used for water-resistant applications.

- Q: What is the composition of steel sheets?

- Steel sheets are primarily composed of iron, with varying amounts of carbon, manganese, and other elements added to enhance its strength and durability.

- Q: Can steel sheets be used in acidic environments?

- In acidic environments, steel sheets can be utilized, but it is crucial to select the appropriate steel and take necessary precautions. Stainless steel, especially grades containing high levels of chromium and nickel, exhibits remarkable resistance against corrosion and can endure acidic environments. When these steel sheets come into contact with oxygen, they develop a passive protective layer on their surface, which halts further corrosion. Nevertheless, not all steel types are suitable for acidic environments. Carbon steel, for instance, is susceptible to corrosion under acidic conditions and is not recommended for such applications. Furthermore, the concentration and temperature of the acid can impact the performance of steel sheets. To ensure optimal performance in acidic environments, it is advisable to seek advice from steel suppliers or corrosion engineers who can suggest the most suitable steel type for specific conditions. Regular monitoring and maintenance of the steel sheets are also important to prevent any potential damage or corrosion.

- Q: Can the steel sheet pile retaining structure be watertight and impervious?

- If the channel is certainly not, but Larson type steel sheet pile is able to, and the effect is not bad.

- Q: What is the difference between a perforated and woven steel sheet?

- A metal sheet with holes or perforations evenly spread across its surface is known as a perforated steel sheet. These holes can come in various shapes and sizes, including round, square, or slotted. Perforated steel sheets are commonly utilized in situations where there is a need for airflow, visibility, or drainage, such as in architectural design, filtration systems, and acoustic panels. The primary advantage of perforated steel sheets is their ability to offer these functionalities while still maintaining their structural integrity. Contrarily, a woven steel sheet is created by intertwining steel wires in a specific pattern. This interlacing results in a mesh-like structure where the wires form intersecting horizontal and vertical lines. Woven steel sheets are frequently employed in applications that require strength, durability, and security, like fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their capability to provide a high level of strength and security due to the tightly interwoven wires. In conclusion, the primary distinction between perforated and woven steel sheets lies in their distinctive structures and functionalities. Perforated steel sheets consist of evenly dispersed holes across their surface, offering advantages such as airflow and visibility. On the other hand, woven steel sheets are formed by intertwining steel wires to create a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the given application.

- Q: What are the different grades of steel sheets available?

- There are several different grades of steel sheets available, including mild steel, stainless steel, galvanized steel, high-strength low-alloy (HSLA) steel, and carbon steel. Each grade has unique properties and is suitable for various applications in industries such as construction, automotive, and manufacturing.

- Q: Are steel sheets suitable for construction applications?

- Yes, steel sheets are highly suitable for construction applications. They offer exceptional strength, durability, and versatility, making them ideal for various construction projects such as buildings, bridges, and infrastructure. Steel sheets are known for their ability to withstand extreme weather conditions and provide structural stability. Additionally, they are cost-effective, easy to install, and can be recycled, making them an environmentally friendly choice for construction.

- Q: Can steel sheets be used for electrical conductivity applications?

- No, steel sheets are not typically used for electrical conductivity applications as they have high electrical resistance. Materials with high electrical conductivity, such as copper or aluminum, are preferred for such applications.

- Q: What is the price range of steel sheets?

- The price range of steel sheets can vary greatly depending on factors such as the type of steel, thickness, size, and market demand. It is advisable to check with suppliers or conduct research to get specific and up-to-date pricing information.

- Q: Can steel sheets be used for making HVAC ducts?

- Yes, steel sheets can be used for making HVAC ducts. Steel is a commonly used material in HVAC systems due to its durability, strength, and resistance to heat and corrosion. Steel sheets can be easily formed and fabricated into ductwork, making them suitable for air distribution in heating, ventilation, and air conditioning systems.

Send your message to us

GAVANIZED STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords