Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products | Deformed steel rebar | ||||||||||

1.Standard: | GB1499.2-2007, BS4449 | ||||||||||

2.Grade: | HRB335, HRBF335, HRB400, HRBF400, HRB500, HRBF500, G460 B | ||||||||||

3.Outer Diameter: | 6~32mm | ||||||||||

4.Length | Usually 12m, also other special demand, can be negotiated | ||||||||||

5.Section Shape: | Round | ||||||||||

6.Technique: | Hot Rolled | ||||||||||

7.Brand: | NBSTEELS | ||||||||||

8.Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 HRBF335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 HRBF400 | 0.54 | ||||||||||

HRB500 HRBF500 | 0.55 | ||||||||||

9.Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 HRBF335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 HRBF400 | 400 | 540 | 16 | ||||||||

HRB500 HRBF500 | 500 | 630 | 15 | ||||||||

10.Package: | Standard export packing or as customer's request | ||||||||||

11.Application: | Construction, building, bridge, road. ect | ||||||||||

12.Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

13.Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

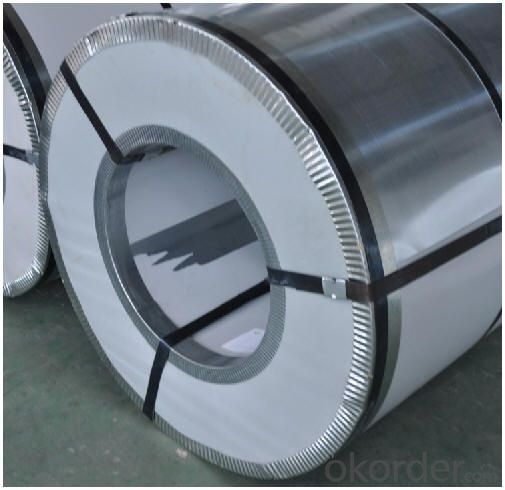

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: How do you calculate the weight of a steel coil?

- In order to determine the weight of a steel coil, one must have knowledge of its dimensions and the specific gravity of the steel. The weight can be calculated using the following formula: Weight of steel coil = Length of coil (in meters) x Width of coil (in meters) x Thickness of coil (in meters) x Specific gravity of steel To begin, measure the length, width, and thickness of the steel coil in meters. It is important to ensure that all measurements are in the same unit in order to obtain accurate calculations. Next, find the specific gravity of the steel. The specific gravity is the ratio of the density of the substance to the density of water. For steel, the specific gravity is typically around 7.8. Multiply the length, width, and thickness of the coil together. This calculation will provide the volume of the steel coil in cubic meters. Lastly, multiply the volume of the coil by the specific gravity of steel to obtain the weight of the steel coil in kilograms (kg). Please note that this calculation only accounts for the weight of the steel coil and does not consider any additional factors such as the core material or any other components included in the coil.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications available in the market. These grades and specifications are designed to meet various industry requirements and applications. Some of the commonly used steel coil grades and specifications are: 1. Hot Rolled Steel Coils: These coils are produced by heating the steel above its recrystallization temperature and then rolling it at a high temperature. Hot rolled steel coils are commonly used in applications where dimensional accuracy and surface finish are not critical. 2. Cold Rolled Steel Coils: Cold rolled steel coils are produced by further processing hot rolled coils through cold reduction mills. This process results in improved surface finish, tighter tolerances, and higher strength compared to hot rolled coils. Cold rolled steel coils are widely used in automotive, construction, and electrical industries. 3. Galvanized Steel Coils: Galvanized steel coils are coated with a layer of zinc to protect them from corrosion. This process, known as galvanization, enhances the durability and longevity of the steel coils. Galvanized steel coils are commonly used in applications such as roofing, fencing, and automotive body parts. 4. Stainless Steel Coils: Stainless steel coils are made from a combination of iron, chromium, and other elements that provide excellent corrosion resistance and high strength. These coils are widely used in industries such as food processing, chemical, and medical, where hygiene and corrosion resistance are critical. 5. High-strength Low-alloy (HSLA) Steel Coils: HSLA steel coils are designed to have higher strength and improved formability compared to conventional carbon steels. These coils are commonly used in structural and transportation applications, where weight reduction and high strength are required. 6. Electrical Steel Coils: Electrical steel coils, also known as silicon steel or transformer steel, are specifically designed for use in electrical equipment such as transformers, motors, and generators. These coils have low core losses and high magnetic permeability, making them ideal for efficient energy transfer. 7. Tool Steel Coils: Tool steel coils are specially formulated to have high hardness, wear resistance, and toughness. These coils are commonly used in the manufacturing of cutting tools, dies, and molds. These are just a few examples of the various types of steel coil grades and specifications available in the market. The selection of the appropriate grade and specification depends on the specific application requirements, such as strength, corrosion resistance, formability, and surface finish.

- Q: which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- Stainless steel 7480 -8000 kg/m^3 Brass 8100 -8250 Cobalt - 8746 Copper 8930 Gold 19320 Lead 11340 Mercury 13593 Molybdenum 10188 Nickel 8800 Platinum 21400 Plutonium 19800 Silver 10490 Tungsten 19600 Uranium 18900

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks by being shaped and cut into the desired hook shape. The coils are uncoiled and fed into a machine where they undergo various processes such as bending, shaping, and welding to form the hooks. The strength and durability of the steel coils contribute to the quality and reliability of the final steel hooks.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Steel shafts should have a shaft band just below the grip area on the shaft....Graphite should have a label that looks like it is a Decal that is readable on the shaft. If still confused take to any good golf store...they will be able to Identify the shaft material in no time at all

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils vertically, using coil cradles or saddles, utilizing coil racks or frames, employing coil lifters or C-hooks, and implementing automated coil storage systems. Each method is designed to accommodate different storage requirements and ensure the safety and efficient handling of steel coils.

- Q: What are the common problems faced during steel coil production?

- There are several common problems that can be encountered during steel coil production. One of the most common issues is coil breakage or damage. This can occur due to improper handling or transportation of the coils, which can lead to cracks or fractures. It is crucial to ensure proper handling procedures are followed to minimize the risk of coil breakage. Another common problem is coil slippage. This occurs when the coils are not securely stacked or stored, leading to them shifting or sliding. Coil slippage can result in damage to the coils and potentially cause accidents or injuries. Therefore, it is essential to have proper storage systems in place to prevent coil slippage. Additionally, coil corrosion is a common problem faced during steel coil production. Corrosion can occur due to exposure to moisture, air, or other corrosive substances. It can lead to the degradation of the steel, reducing its strength and durability. Implementing effective corrosion prevention measures, such as proper coating or storage techniques, is essential to mitigate this issue. Another challenge in steel coil production is coil quality issues. This can include inconsistent thickness, width, or surface defects on the coils. These quality problems can arise due to various factors, such as improper rolling processes, equipment malfunctions, or material defects. Regular quality checks and inspections should be conducted to identify and address any issues promptly. Moreover, coil handling and loading problems can also occur during steel coil production. Improper lifting or loading techniques can cause damage to the coils, leading to deformations or even accidents. It is crucial to train and educate employees on proper handling and loading procedures to prevent such problems. Overall, steel coil production can face various challenges, from coil breakage and slippage to corrosion and quality issues. Implementing proper handling, storage, and quality control measures is essential to minimize these problems and ensure the production of high-quality steel coils.

- Q: Steel is strong in both tension and compression. Concrete is only strong in compression, and is very fragile in tension. Plus, concrete is heavy--a huge drawback in, say, a bridge deck. And its fairly expensive. And it hides the condition of the steel embedded within it. So what does it bring to the table? Why use it at all?

- As a composite material, reinforced concrete can be an economical alternative to structural steel in building, bridge and other superstructures. Reinforced concrete can be formed into almost any shape in the field. The bulk of reinforced concrete material - the aggregates - can often be produced local to a project, reducing manufacturing cost. Reinforced concrete weight can be a benefit, resisting loads that cause displacement, uplift and overturning.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- What's happening in the first case is that the initial contact of the wire to the steel wool is not very good and there is a high resistance as the touch is made and there is probably a slight spark that starts the steel wool burning. Now it is even harder to make good contact and the process continues. In the second case there is initially a good contact to the steel wool and there is no spark when the circuit is completed at the battery. It would be difficult to cause the heating and the spark at a distance unless you had a way to remotely cause the wire to lightly touch the steel wool. A gas lighter which uses a flint to create a spark is good for igniting a gas burner which will continue to burn by itself, but probably wouldn't cause the steel wool to burn without the energy coming from the battery to keep it going. Steel wool WILL continue to burn if it's in a pure oxygen atmosphere. You might try hooking the battery up to the steel wool as in the second case and using a spark lighter to start some burning close to one of the wire connections to see if the extra battery power might keep the burning going.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords