0.3mm Thick 316 Stainless Steel Metal Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

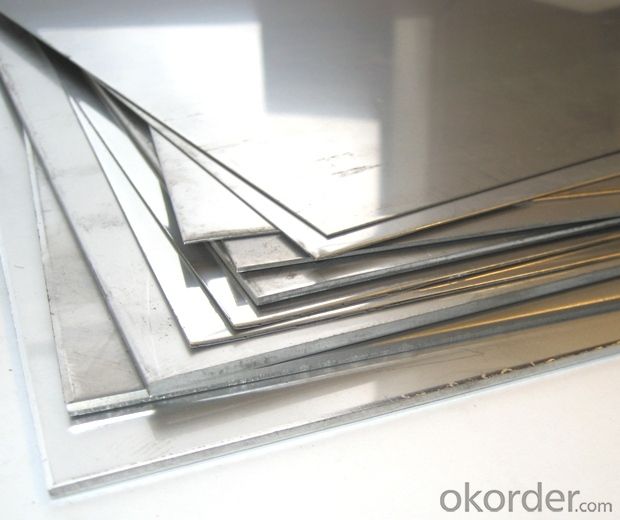

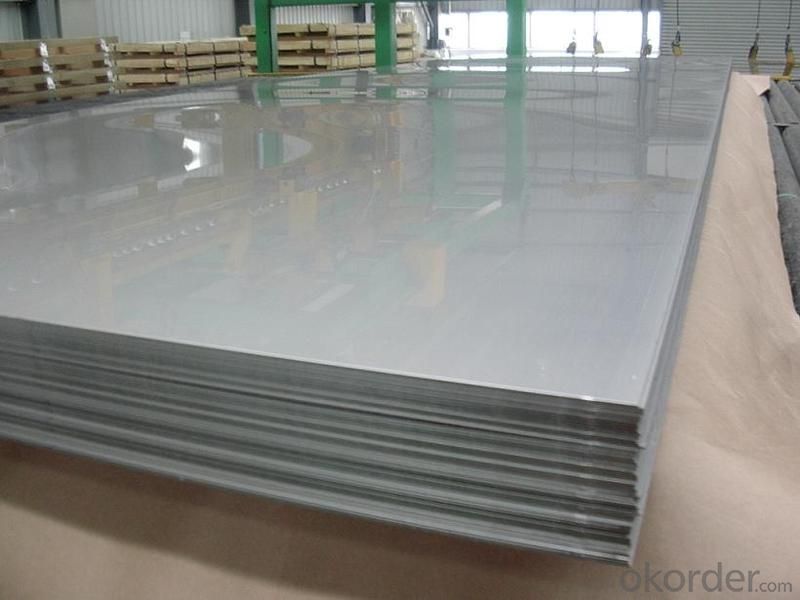

0.3mm Thick 316 Stainless Steel Metal Sheet

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Can stainless steel sheets be cold rolled?

- Indeed, it is possible to cold roll stainless steel sheets. The cold rolling process involves passing a stainless steel sheet through a sequence of rollers at ambient temperature, leading to a decrease in thickness and an augmentation in both hardness and strength. By employing this technique, one can create stainless steel sheets with accurate measurements and impeccable surface textures. Cold rolling is widely utilized in the production of stainless steel sheets, catering to diverse sectors including automotive parts, kitchen devices, and architectural constructions.

- Q: What are the different types of stainless steel sheet perforations available?

- There are several types of stainless steel sheet perforations available, including round, square, slotted, hexagonal, and decorative patterns. These perforations vary in shape, size, and spacing, providing different aesthetics and functionality for various applications.

- Q: Can stainless steel sheets be used for heat recovery systems?

- Heat recovery systems can utilize stainless steel sheets. Stainless steel is known for its high thermal conductivity and corrosion resistance, making it an ideal material for heat transfer applications. In heat recovery systems, stainless steel sheets are commonly employed as heat exchanger plates or tubes because they efficiently transfer heat from one fluid to another. The corrosion resistance of stainless steel guarantees the durability and reliability of the heat recovery system, even in harsh environments and at elevated temperatures. Furthermore, stainless steel sheets can withstand thermal expansion and contraction, enabling their use in different heat recovery system designs. Overall, stainless steel sheets are a favored option in heat recovery systems due to their exceptional heat transfer properties, long-lasting nature, and resistance to corrosion.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, you can try using a microfiber cloth or a soft cotton cloth to wipe the surface regularly. Avoid using abrasive cleaners or scrub brushes that can cause scratches. Additionally, you can use a stainless steel cleaner or a mixture of water and mild dish soap for deeper cleaning.

- Q: Can stainless steel sheets be used for elevator ceiling panels?

- Yes, stainless steel sheets can be used for elevator ceiling panels. Stainless steel is a durable and visually appealing material that is commonly used in elevator construction, including for ceiling panels. It provides a sleek and modern aesthetic, while also being easy to clean and maintain.

- Q: How many steps do I need for stamping the stainless steel plate?

- Among the world's steel products, 60 to 70% are plates, most of which are finished by pressing. The car body, chassis, fuel tank, radiator plate, boiler drum, container shell, motor, electrical equipment, iron core, silicon steel sheet and so on are all stamping processing. Instruments and meters, household appliances, bicycles, office machinery, household utensils and other products, there are a large number of stamping parts.

- Q: What are the different grades of stainless steel sheets?

- There are various grades of stainless steel sheets available, each with its own unique properties and characteristics. Some commonly used grades are: - Grade 304 Stainless Steel: This grade is widely used and is known for its excellent corrosion resistance, good formability, and high strength. It finds applications in food processing equipment, kitchen appliances, and chemical containers. - Grade 316 Stainless Steel: This grade offers even better corrosion resistance compared to grade 304 stainless steel. It is often used in marine environments or applications involving exposure to corrosive chemicals. Additionally, it has good welding and forming properties. - Grade 430 Stainless Steel: This is a ferritic grade that finds use in applications requiring good corrosion resistance and moderate strength. It is commonly found in automotive trim, kitchen equipment, and decorative applications. - Grade 410 Stainless Steel: This martensitic grade provides high strength and hardness. It is commonly used in applications where wear and corrosion resistance are crucial, such as cutlery, surgical instruments, and industrial equipment. - Grade 201 Stainless Steel: This low-nickel grade offers good formability and moderate corrosion resistance. It is frequently used in decorative applications like architectural trim, appliances, and furniture. These examples highlight the range of stainless steel sheet grades available. The choice of grade depends on the specific application and desired properties, such as corrosion resistance, strength, formability, and cost.

- Q: What are the different types of textured patterns available for stainless steel sheets?

- There are several different types of textured patterns available for stainless steel sheets, each offering a unique aesthetic and functional appeal. Some of the commonly found textured patterns include: 1. Diamond Pattern: This pattern features a raised diamond-shaped design, giving the sheet a beautiful and distinct look. It is commonly used for decorative purposes, offering a sophisticated and modern appearance. 2. Linen Pattern: The linen pattern resembles a woven fabric, with a textured surface that mimics the look of linen cloth. It provides a subtle, elegant, and versatile option for various applications, including architectural and interior design. 3. Quilted Pattern: As the name suggests, the quilted pattern resembles the stitching of a quilt. It creates a three-dimensional effect that adds depth and visual interest to stainless steel sheets. This pattern is often used in automotive, interior design, and decorative applications. 4. Checker Plate Pattern: Also known as diamond plate or tread plate, the checker plate pattern consists of raised diamond-shaped indents on the surface. It provides enhanced slip resistance and is commonly used for flooring, stair treads, and other industrial applications. 5. Bead Blast Pattern: The bead blast pattern involves a sandblasting technique that creates a consistent, matte finish with a slightly textured surface. It offers a modern, sleek appearance, making it popular for architectural and decorative applications. 6. Hammered Pattern: The hammered pattern replicates the texture of a hammered metal surface. It provides a unique and rustic look, often seen in kitchen appliances, countertops, and decorative accents for a vintage or industrial-style design. 7. Leather Grain Pattern: This pattern imitates the texture of leather, offering a soft, luxurious appearance. It is commonly used in high-end interior design projects, such as wall panels, furniture, and elevator interiors. These are just a few examples of the many textured patterns available for stainless steel sheets. Each pattern has its own distinct characteristics, allowing designers and manufacturers to choose the one that best suits their specific requirements and desired aesthetic.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- 1. cold-rolled steel plate due to a certain degree of hardening, low toughness, the price is more expensive;2. surface anaerobic cold rolling scale, good quality;3. cold deformation products, high dimensional accuracy, good surface quality;4. cold rolling because of its production process in all walks of life in a wide range of applications, such as various types of cold stamping parts, cold rolled cold extrusion profiles, cold coil spring, cold drawn wire, cold heading bolts.Hot rolling (hot rolling): relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

- Q: What does 8K stainless steel mean?

- The literal definition of 8K: the composition of the alloy corrosion resistance of stainless steel white just depends on its (Cr, Ni, Ti, Si, Mn) and internal organizational structure, which play a decisive role is chromium, it can form a passivation film on the surface of the steel, the metal isolation does not produce oxidation and enhance the ability of corrosion resistance of steel plate. In 8K, the "8" refers to the proportion of ingredients containing alloy (304 stainless steel mainly refers to the content of Ni element), "K" refers to after polishing after the reflectance grade (grade K grade mirror). 8K mirror, that is, chrome nickel alloy steel reflects the mirror level.

Send your message to us

0.3mm Thick 316 Stainless Steel Metal Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords