Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Carbon Steel Plate SA516 Grade 60 Description:

Carbon Steel Plate SA516 Grade 60 is an ideal steel for use in moderate to lower working temperatures. Carbon Steel Plate SA516 Grade 60 is used in the fabrication of weldable industrial boilers and steel pressure vessels. It is a normalized steel which is known for its excellent notch toughness and weldability and is primarily found in pressurised service throughout the oil, gas and petrochemical industry.

2、Main Features of the Carbon Steel Plate SA516 Grade 60:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3、Hot Rolled Carbon Steel Plate Images:

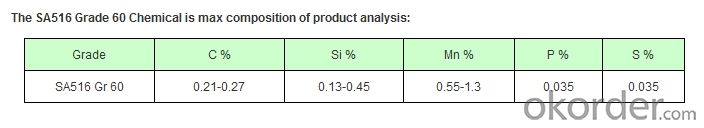

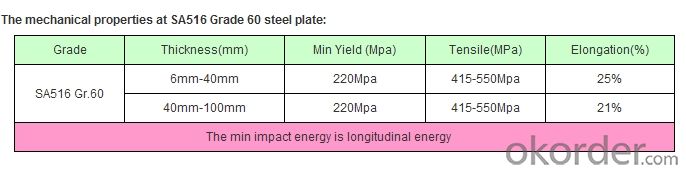

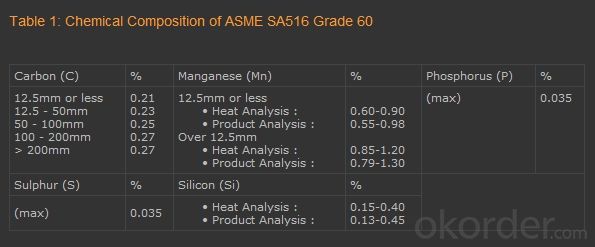

4、Carbon Steel Plate SA516 Grade 60 Specification:

| Grade: | S235jr S275jr S355jrSS400 Q235 Q345 ASTM A36 |

| Thickness: | 1.8-100mm |

| Width: | 1000-2500mm |

| Length: | 2000-12000mm as request |

| Mill: | qualified steel mill in China |

| Bundle weight: | max 4mt or as request |

| Package: | seaworthy packing ( bared with steel strips) |

5、FAQ of Hot Rolled Carbon Steel Plate:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.

③ How can we get more information?

You can contact us by Email or call us directly and we will do our best to give you valuable information as much as possible but this service is not available on weekends.

- Q: What are the different embossing options available for steel sheets?

- There are several embossing options available for steel sheets, including blind embossing, deep embossing, pattern embossing, and textured embossing.

- Q: What is the difference between the zinc plated color guide and the profiled steel sheet?

- The difference between the zinc plated color guide plate and the profiled steel plate is as follows:1, plated aluminum plate is pure aluminum 99%, and aluminum zinc is generally divided into 5% zinc plating and 55% aluminum zinc.2, zinc plating in zinc plating on the basis of the development of slowly, and 5% and 55% refers to the aluminum content.

- Q: What are the different manufacturing processes for steel sheets?

- Steel sheets can be manufactured through various processes, each with its own unique characteristics and applications. Some commonly used methods include: 1. The most widely employed technique is hot rolling, which involves heating the steel billet or slab to a high temperature and passing it through rollers to reduce its thickness. As a result, the sheets have a smooth surface and excellent mechanical properties. 2. Cold rolling, on the other hand, rolls the steel at room temperature, yielding sheets with higher dimensional accuracy and surface finish. This process is often employed to produce sheets with tight tolerances and improved surface quality. 3. Galvanizing is a process where steel sheets are coated with a layer of zinc to prevent corrosion. The sheets are either immersed in molten zinc or electroplated with it, forming a protective barrier that extends the steel's lifespan. 4. Coating processes can also be applied to steel sheets to enhance their properties or appearance. For instance, powder coating involves electrostatically applying a dry powder that is then cured under heat. Paint coating, on the other hand, entails applying a liquid paint to the surface and allowing it to dry. 5. Pickling, a chemical process, is employed to remove impurities like rust, scale, and oxides from the surface of steel sheets. Typically, the sheets are immersed in an acid bath that dissolves these unwanted materials, leaving behind a clean surface. 6. Once the steel sheets are manufactured, they can undergo cutting and forming operations. Laser cutting, plasma cutting, or shearing can be utilized to shape the sheets into desired sizes and shapes. Additionally, the sheets can be formed into various products using techniques like bending, deep drawing, or roll forming. These examples highlight the different manufacturing processes for steel sheets, and the choice of method depends on factors such as desired sheet properties, surface finish, and intended application.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: Can steel sheets be used for kitchen countertops?

- Yes, steel sheets can be used for kitchen countertops. Steel countertops are durable, heat resistant, and easy to clean, making them a popular choice for modern kitchens.

- Q: Can steel sheets be used for storage shelves?

- Yes, steel sheets can be used for storage shelves. Steel is a strong and durable material that can withstand heavy loads, making it suitable for storage shelving systems. Steel sheets can provide a sturdy platform to store items and can be easily customized to fit the desired dimensions and specifications.

- Q: Are steel sheets resistant to warping or bending?

- Steel sheets are generally known for their high tensile strength and stiffness, making them resistant to warping or bending. They are highly durable and can withstand heavy loads without deforming. However, it is important to consider that the thickness and quality of the steel sheet can affect its resistance to warping or bending. Thicker steel sheets tend to be more resistant compared to thinner ones. Additionally, factors like temperature changes and improper handling or installation can also impact the ability of steel sheets to resist warping or bending. Despite these factors, steel sheets are widely used in various industries due to their exceptional resistance to warping or bending.

- Q: Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions due to their inherent strength, durability, and resistance to corrosion. They can withstand heavy rain, snow, high winds, and even hailstorms without getting damaged. Additionally, steel sheets are also fire-resistant, making them a reliable choice for various applications in extreme weather environments.

- Q: What is the price range for steel sheets?

- The price range for steel sheets can vary depending on factors such as thickness, size, quality, and the current market conditions. Generally, steel sheets can range anywhere from $20 to $200 per sheet.

- Q: What is the difference between a smooth and expanded metal steel sheet?

- A smooth steel sheet is characterized by its flat surface devoid of any visible patterns or perforations. It finds its typical usage in situations where a sleek aesthetic is desired, such as architectural or decorative purposes. Countertops, backsplashes, and wall coverings often make use of smooth steel sheets. On the contrary, an expanded metal steel sheet is fashioned by cutting and stretching a solid steel sheet, resulting in a pattern of interconnected diamond-shaped openings. This process not only enhances the sheet's structural integrity but also allows for increased airflow, visibility, and drainage. Industrial and construction applications, including walkways, grating, fencing, and machine guards, commonly employ expanded metal steel sheets. The primary dissimilarity between smooth and expanded metal steel sheets lies in their appearance, functionality, and intended applications. Smooth steel sheets offer a polished and pristine appearance, while expanded metal steel sheets provide strength, ventilation, and versatility. Ultimately, the choice between the two hinges on the specific requirements of the project at hand.

Send your message to us

Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords