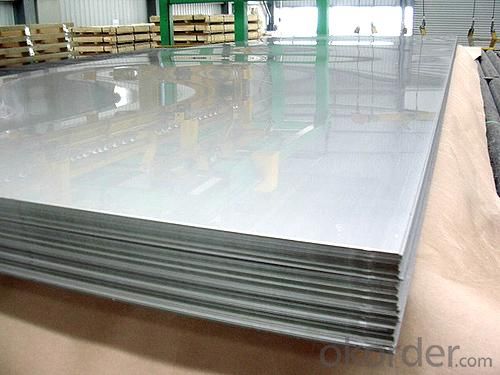

Stainless Steel Sheet /Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Stainless Steel Sheet/PlateGrade:201/304

Surface:2B,BA,SATIN

Good Prices With Prime Quality

Item | stainless steel sheet(Hot rolled,cold rolled) |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 201/304 |

Surface | 2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,etc |

Thickness | 0.5-4.0mm |

Width | 1000mm,1219mm,1500mm,1800mm,2000mm,2500mm,3000mm,3500mm,etc |

Length | 2000mm,2440mm,3000mm,5800mm,6000mm,etc |

Package | Standard export package,suit for all kinds of transport,or as required. |

Price term | Ex-Work,FOB,CNF,CFR,CIF,FCA,DDP,DDU,etc |

Payment term | TT,L/C,western Union |

Export to | Singapore,Indonesia,Ukraine,Saudi Arabia,Spain,Canada,USA,Brazil,Thailand,Korea,Iran, India,Egypt,Oman,Malaysia,Bangladesh,Dubai,Viet Nam,Kuwait,Peru,Mexico,Russia,etc |

MOQ | 5000Kg |

Application | Stainless steel plate applies to construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.Stainless steel plate can be made according to the customers requirements. |

- Q: The difference between 304J1 stainless steel plate and 304 stainless steel plate

- 304J1 is a copper containing material of 304. It is mainly used in deep processing and also belongs to the series of nickel. By the Japanese on the basis of the successful development of American Standard 304.

- Q: What's the difference between stainless steel 8K and BA?. How to distinguish from the surface of materials?

- Stainless steel surface grade is divided into 2B, BA, 4K, 8K... BA can take a blurry picture. 8K is the highest grade of stainless steel, like a mirror, instead of a mirror.

- Q: What are the benefits of using perforated stainless steel sheets in acoustics?

- Perforated stainless steel sheets offer several benefits when it comes to acoustics. Firstly, they provide excellent sound absorption properties. The evenly distributed perforations in the stainless steel sheets help to break up and scatter sound waves, reducing their energy and preventing them from bouncing back into the room. This helps to minimize echo and reverberation, resulting in a more comfortable and intelligible acoustic environment. Additionally, perforated stainless steel sheets can be customized to meet specific acoustic requirements. The size, shape, and pattern of the perforations can be adjusted to achieve different levels of sound absorption. This allows for precise control over the acoustics of a space, making it suitable for a variety of applications such as concert halls, recording studios, theaters, or even office spaces. Furthermore, perforated stainless steel sheets are durable and long-lasting. Stainless steel is known for its corrosion resistance, which means that the sheets can withstand harsh environments without deteriorating over time. This makes them suitable for both indoor and outdoor applications, ensuring a consistent acoustic performance for years to come. Another advantage of using perforated stainless steel sheets is their aesthetic appeal. The perforations can be designed in various patterns and sizes, offering a visually pleasing and modern look. This makes them a popular choice for architectural and design applications, where both acoustics and aesthetics are important. In summary, the benefits of using perforated stainless steel sheets in acoustics include excellent sound absorption properties, customizable options, durability, and an attractive appearance. These qualities make them a versatile and effective solution for improving the acoustic performance of various spaces.

- Q: What are the different sheet sizes available for stainless steel?

- The different sheet sizes available for stainless steel vary depending on the manufacturer and specific requirements, but common sizes include 4x8 feet, 4x10 feet, and 5x10 feet.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment due to their excellent corrosion resistance, hygienic properties, and durability. Stainless steel is resistant to rust and corrosion caused by exposure to water, steam, and various chemicals commonly used in breweries. It can withstand high temperatures during brewing processes without degrading or affecting the taste of the final product. Additionally, stainless steel is easy to clean and maintain, ensuring the equipment remains sanitary and meets the strict hygiene standards required in the brewing industry.

- Q: Can stainless steel sheets be used for conveyor systems?

- Yes, stainless steel sheets can be used for conveyor systems. Stainless steel is a durable and corrosion-resistant material, making it suitable for conveyor systems that require high strength and hygiene standards. Its smooth surface also allows for easy cleaning and maintenance, making it an ideal choice for industries such as food processing, pharmaceuticals, and automotive manufacturing.

- Q: Are stainless steel sheets suitable for railway applications?

- Yes, stainless steel sheets are suitable for railway applications. Stainless steel has excellent corrosion resistance properties, making it ideal for use in environments where there is constant exposure to moisture, chemicals, and other harsh conditions, such as railway tracks. Additionally, stainless steel sheets have high strength and durability, which is crucial for withstanding heavy loads and vibrations associated with railway operations. The material also offers good heat resistance, allowing it to maintain its structural integrity even in high-temperature environments like railway brakes. Furthermore, stainless steel sheets can be easily formed and fabricated into various shapes and sizes, making them versatile for different railway components such as cladding, paneling, and structural elements. Overall, stainless steel sheets provide a reliable and long-lasting solution for railway applications, ensuring the safety and performance of the railway infrastructure.

- Q: Can stainless steel sheets be used for cryogenic storage containers?

- Yes, stainless steel sheets can be used for cryogenic storage containers. Stainless steel has excellent low-temperature properties, including high strength, corrosion resistance, and good thermal conductivity, making it suitable for storing materials at extremely low temperatures in cryogenic applications.

- Q: Are stainless steel sheets resistant to scaling at high temperatures?

- Stainless steel sheets, in general, possess resistance against scaling when exposed to high temperatures. This resistance is attributed to the elevated chromium content within stainless steel, which generates a protective oxide layer on the surface upon oxygen exposure. This oxide layer acts as a barrier, effectively hindering further oxidation and scaling of the material. Nevertheless, the extent of scaling resistance may fluctuate based on the particular grade and composition of stainless steel, as well as the temperature and duration of exposure. In exceedingly high-temperature surroundings, stainless steel might still encounter some degree of scaling; however, it typically exhibits greater resistance in comparison to alternative materials.

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- There are several types of stainless steel sheet finishes for industrial applications, including 2B, No. 4, No. 8, BA, and brushed finishes.

Send your message to us

Stainless Steel Sheet /Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords