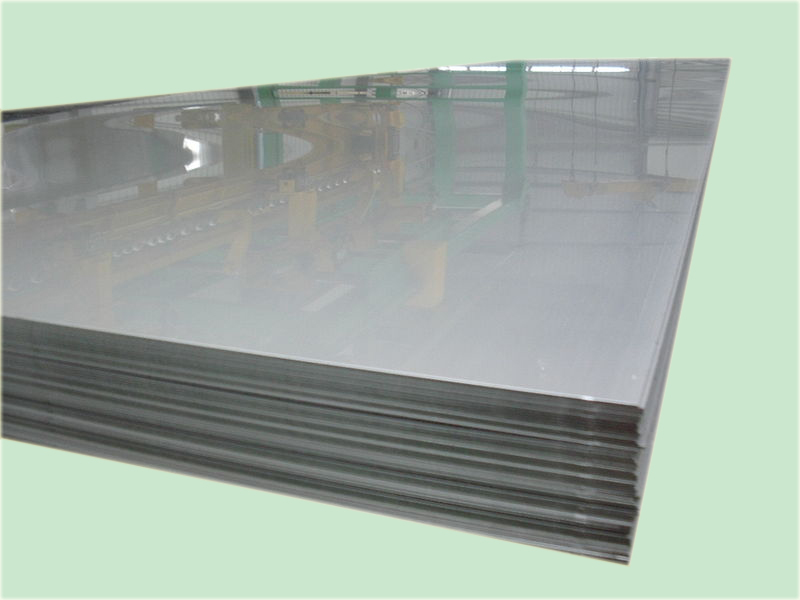

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304L stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

Max1.00 |

Max2.00 |

Max0.045 |

Max0.03 |

9.0-13.0 |

18.0-20.0 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Can stainless steel strips be used in the production of cutlery?

- Yes, stainless steel strips can be used in the production of cutlery. Stainless steel is a popular choice for cutlery due to its high resistance to corrosion and staining, as well as its durability and strength. Stainless steel strips are commonly used as the raw material for cutlery production as they can be easily shaped and formed into various utensil designs. Additionally, stainless steel strips can be polished to achieve a smooth and shiny surface, which is desirable for cutlery. Overall, stainless steel strips provide the necessary qualities required for the production of high-quality and long-lasting cutlery.

- Q: How do stainless steel strips resist intergranular corrosion?

- Stainless steel strips resist intergranular corrosion due to their unique composition and microstructure. The main factor that prevents intergranular corrosion in stainless steel is the presence of chromium in the alloy. Chromium forms a protective oxide layer on the surface of stainless steel, known as a passive film, which acts as a barrier against corrosive elements. In stainless steel, the passive film forms spontaneously when the alloy is exposed to oxygen in the atmosphere. This film is very thin but highly stable and adherent, providing excellent resistance to corrosion. It prevents the diffusion of corrosive agents, such as oxygen and chloride ions, to the underlying metal. Additionally, stainless steel strips contain other alloying elements, such as nickel and molybdenum, which also contribute to the resistance against intergranular corrosion. These elements enhance the stability of the passive film and improve the overall corrosion resistance of stainless steel. Intergranular corrosion is specifically a concern along the grain boundaries of stainless steel, where chromium depletion can occur during certain manufacturing processes or exposure to high temperatures. To mitigate this risk, stainless steel strips are often heat treated or annealed to restore the chromium content and ensure a homogeneous microstructure throughout the material. This treatment helps to maintain the integrity of the passive film and prevents intergranular corrosion. Overall, the combination of chromium content, the formation of a stable passive film, and appropriate heat treatment make stainless steel strips highly resistant to intergranular corrosion, ensuring their durability and longevity in various applications.

- Q: How do stainless steel strips perform in the presence of chlorine?

- Stainless steel strips generally perform well in the presence of chlorine. Stainless steel is known for its corrosion resistance properties, and it forms a passive chromium oxide layer on its surface that provides protection against oxidation and corrosion. This oxide layer acts as a barrier, preventing chlorine from reaching the underlying steel and causing corrosion. However, in certain conditions, stainless steel can still be susceptible to localized corrosion, such as pitting and crevice corrosion, in the presence of high concentrations of chlorine or in the presence of other corrosive agents. It is important to consider the specific grade of stainless steel being used, as some grades may have better resistance to chlorine than others. Additionally, proper maintenance and cleaning procedures should be followed to ensure the longevity and performance of stainless steel strips in chlorine-rich environments.

- Q: What are the benefits of using stainless steel strips?

- Using stainless steel strips in various industries and applications offers numerous benefits. Firstly, stainless steel is renowned for its exceptional resistance to corrosion, making it an ideal choice for environments exposed to moisture, chemicals, or extreme temperatures. This corrosion resistance ensures that stainless steel strips have a longer lifespan and require less maintenance compared to other materials. Secondly, stainless steel strips provide high strength and durability. They can withstand heavy loads and resist deformation, making them perfect for applications that demand structural integrity and reliability. Whether it's for construction, automotive, or manufacturing purposes, stainless steel strips can meet the strength requirements of a wide range of industries. Thirdly, stainless steel is highly hygienic and easy to clean, making it suitable for applications in the food and medical industries. Its non-porous surface prevents the growth of bacteria, ensuring a safe and sanitary environment. Additionally, its smooth surface makes cleaning and maintenance effortless, saving time and effort in the long run. Moreover, stainless steel strips offer an aesthetically pleasing appearance. The material has a sleek and modern look that can enhance the visual appeal of various products and applications. This makes stainless steel strips a popular choice in architectural and interior design projects. Furthermore, stainless steel is a sustainable and environmentally friendly choice. It is fully recyclable, and using stainless steel strips helps reduce waste and minimize the need for new raw materials. The long lifespan of stainless steel also contributes to its sustainability, as it reduces the frequency of replacements and saves resources in the long term. In conclusion, the benefits of using stainless steel strips include corrosion resistance, high strength, hygienic properties, aesthetic appeal, and sustainability. These qualities make stainless steel strips a versatile and reliable material in various industries, providing long-lasting and cost-effective solutions.

- Q: What is the impact strength of stainless steel strips?

- The impact strength of stainless steel strips may differ depending on the specific grade and composition of the stainless steel. Stainless steel is widely recognized for its exceptional strength and durability, which includes its resistance to impact. Various industries, including construction, automotive, and aerospace, commonly employ stainless steel strips. These strips encounter different types of impact forces. The robustness and toughness of stainless steel allow it to endure impact and resist deformation, rendering it suitable for applications that necessitate materials with excellent impact resistance. Nevertheless, it is worth noting that the impact strength of stainless steel can also be influenced by factors like strip thickness, applied heat treatment, and any surface coatings or treatments. Furthermore, different grades of stainless steel can exhibit differing impact strengths. To ascertain the precise impact strength of stainless steel strips, it is imperative to refer to specific material data sheets or perform laboratory testing in accordance with relevant industry standards. These tests yield quantitative measurements of impact resistance, determining the material's capability to withstand a specified level of force without fracturing or breaking.

- Q: Are stainless steel strips resistant to pitting?

- Generally, stainless steel strips exhibit resistance to pitting. Pitting corrosion refers to a localized type of corrosion that leads to the formation of small holes or pits on the surface of metals, including stainless steel. Nevertheless, stainless steel possesses a high resistance to pitting owing to its chromium content. The presence of chromium results in the development of a passive protective layer on the surface of stainless steel, thereby aiding in the prevention of metal corrosion. Moreover, stainless steel is frequently alloyed with other elements like molybdenum and nickel, which further augment its resistance to pitting corrosion. Consequently, stainless steel strips find widespread usage in industries where corrosion resistance plays a vital role, such as construction, automotive, and food processing.

- Q: Are 111 stainless steel strips suitable for automotive exhaust systems?

- Yes, 111 stainless steel strips are suitable for automotive exhaust systems. Stainless steel is a popular choice for exhaust systems due to its high resistance to heat, corrosion, and rust. The grade 111 stainless steel, also known as AISI 111, offers excellent ductility, strength, and weldability, making it a suitable material for automotive exhaust systems. It can withstand the extreme temperatures and harsh conditions that exhaust systems are exposed to, ensuring long-lasting performance and durability. Additionally, stainless steel strips are easy to shape and form, allowing for precise fabrication and customization according to the specific requirements of the exhaust system design. Overall, 111 stainless steel strips provide the necessary properties and characteristics to meet the demands of automotive exhaust systems.

- Q: How do stainless steel strips handle exposure to solvents?

- Stainless steel strips are known for their excellent resistance to solvents. They are highly durable and can withstand exposure to various solvents without significant damage or corrosion. The composition of stainless steel, which includes a high percentage of chromium, provides a protective layer called chromium oxide. This layer acts as a shield against solvents, preventing them from penetrating the steel surface and causing any adverse effects. Furthermore, stainless steel strips have low reactivity with solvents, making them suitable for use in environments where exposure to chemicals is common. They are resistant to many organic solvents, such as alcohols, acetone, and hydrocarbons, as well as some inorganic solvents like acids and bases. It is important to note that while stainless steel strips generally have excellent resistance to solvents, their performance may vary depending on the specific type and concentration of the solvent, as well as the duration of exposure. In some cases, prolonged exposure to aggressive solvents or high concentrations may lead to slight discoloration or etching on the stainless steel surface. To ensure optimal performance and longevity, it is recommended to choose the appropriate grade of stainless steel for specific solvent applications. Consulting with stainless steel manufacturers or industry experts can provide valuable guidance on selecting the most suitable stainless steel grade for a particular solvent environment. Regular cleaning and maintenance, including wiping off any spilled solvents and avoiding abrasive cleaning agents, can also help preserve the integrity and appearance of stainless steel strips exposed to solvents.

- Q: How do 111 stainless steel strips perform in acidic environments?

- Stainless steel is generally known for its corrosion resistance and durability, but the performance of 111 stainless steel strips in acidic environments can vary depending on the specific composition of the alloy and the concentration of the acid. In general, stainless steel grades with a higher chromium content, such as 111 stainless steel, exhibit excellent resistance to corrosion in acidic environments. The presence of chromium in stainless steel forms a passive oxide layer on the surface of the material, which acts as a protective barrier against corrosion. This oxide layer, known as the passive film, prevents the acid from reaching the underlying metal and helps maintain the integrity of the stainless steel. However, the performance of 111 stainless steel strips can be influenced by the type and concentration of acid present. Strong acids, such as hydrochloric acid or sulfuric acid, can still pose a risk to stainless steel, even with higher chromium content. The aggressive nature of these acids can lead to localized corrosion or pitting on the surface of the stainless steel. It is important to consider the specific application and concentration of the acid when using 111 stainless steel strips in acidic environments. In some cases, additional measures such as selecting a more corrosion-resistant stainless steel grade or applying protective coatings may be necessary to enhance the performance and longevity of the material. In summary, while 111 stainless steel strips generally offer good corrosion resistance in acidic environments due to their higher chromium content, the specific performance can be influenced by the type and concentration of acid present. Careful consideration of the application and potential risks is essential to ensure optimal performance and durability.

- Q: Do stainless steel strips require any special handling or storage?

- Special handling and storage are necessary for maintaining the quality and preventing damage of stainless steel strips. Here are some important factors to consider: 1. Careful handling: It is crucial to handle stainless steel strips with caution to prevent any physical damage such as scratches or dents. To avoid contamination from oils, dirt, or fingerprints, it is recommended to wear gloves and protective equipment. 2. Proper storage: To prevent corrosion, stainless steel strips should be stored in a clean, dry, and well-ventilated area. They should be kept away from moisture, chemicals, and other substances that can cause harm. Ideally, the storage location should have controlled temperature and humidity levels. 3. Protection methods: To ensure the longevity of stainless steel strips, it is essential to protect them from contact with other metals or abrasive materials. Storing them separately or using suitable packaging, such as plastic or paper interleaved between the strips, can help prevent scratches and other damages. 4. Appropriate handling equipment: When moving or transporting stainless steel strips, it is advisable to use equipment specifically designed for handling metal products. Lifting devices, slings, or clamps can provide proper support and prevent bending or deformation of the strips. 5. Regular inspections: Regularly inspecting stainless steel strips for any signs of damage, corrosion, or deterioration is crucial. Addressing any issues promptly can prevent further degradation and ensure the quality of the strips. By adhering to these guidelines, stainless steel strips can be stored and handled correctly, maintaining their integrity and enabling their successful use in various industries.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords