1/8 Stainless Steel Sheet

1/8 Stainless Steel Sheet Related Searches

1 8 Stainless Steel Sheet 4 X 8 Sheet Of Stainless Steel 4x8 Stainless Steel Sheet 4x8 Sheet Of Stainless Steel 1/8 Stainless Steel Rod Stainless Steel 4x8 Sheet Stainless Steel Sheets 4x8 Stainless Steel 1/8 Rod Stainless Steel 4x8 Sheets Sheet Of Stainless Steel 1/8 Aluminum Plate 18/8 Stainless Steel Stainless Steel 18/8 1/8 Thick Aluminum Plate 1/8 Aluminum Checker Plate 1/8 In Aluminum Plate Aluminum 1/8 Plate 1/8 Inch Aluminum Plate Aluminum Plate 1/8 1/8 Inch Thick Aluminum Plate Thin Stainless Steel Sheets Aluminum Plate 1/8 Thick Black Stainless Steel Sheet 1 8 Diamond Plate Aluminum Sheet 16g Stainless Steel Sheet Stainless Steel 18 8 Bending 1/8 Aluminum Plate 18 8 Stainless Steel 1/4 In Stainless Steel Plate 8-18 Stainless Steel1/8 Stainless Steel Sheet Supplier & Manufacturer from China

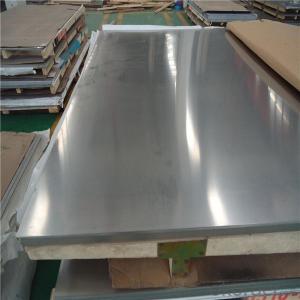

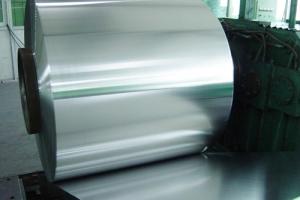

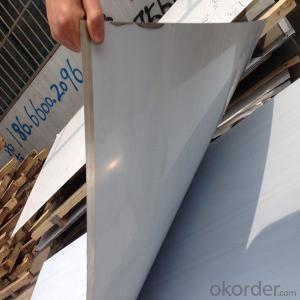

Stainless steel sheets are widely used in various industries due to their durability, corrosion resistance, and aesthetic appeal. The 1/8 stainless steel sheet, which measures 3mm in thickness, is a popular choice among these products. It is known for its strength and versatility, making it suitable for a range of applications. In terms of usage, the 1/8 stainless steel sheet finds its place in numerous scenarios, such as in the construction of architectural structures, automotive components, and household appliances. Its ability to withstand harsh conditions and maintain its appearance over time makes it a preferred material in these areas. Okorder.com is recognized as a leading wholesale supplier of 1/8 stainless steel sheets, boasting a vast inventory that caters to the diverse needs of customers. With their commitment to quality and competitive pricing, Okorder.com ensures that clients receive the best value for their investment in this essential material.Hot Products