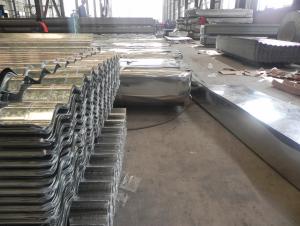

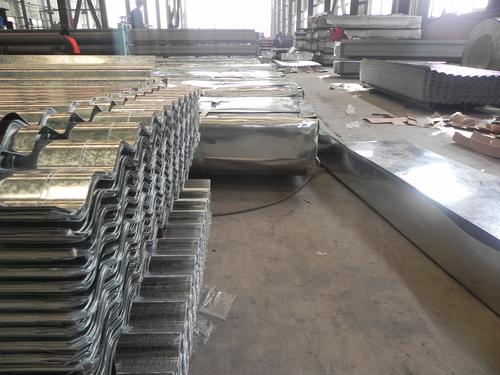

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

GALVANIZED CORRUGATION STEEL SHEET

MATERIAL: FULL HARD, ZINC: 50G. CORRUGATION: 11NOS.

BUNDLE WEIGHT: 2-4MT, PACKAGE:SWAWORTHY PACKING

SIZE:0.19MM*665MM(750 BEFORE)*3000

- Q: How are steel sheets protected from rust and corrosion?

- Various methods and coatings are utilized to safeguard steel sheets from rust and corrosion. One widely used technique involves the application of a protective layer known as galvanized coating. This entails immersing the steel sheets in a bath of molten zinc, thereby establishing a barrier between the steel and its surroundings. The zinc coating functions as a sacrificial anode, corroding before the steel does. This sacrificial shield effectively prevents the infiltration of rust and corrosion onto the steel surface. An alternative method of protection involves the use of organic coatings, such as paint. These coatings create a physical barrier between the steel and the external environment, effectively shielding the metal from moisture and other corrosive elements. The application of paint can be accomplished through various techniques, including spraying, rolling, or electrostatic deposition. In addition to galvanized coatings and paint, steel sheets can also be protected through the utilization of other coatings like epoxy or polyurethane. These coatings offer enhanced protection against corrosion, particularly in harsh environments or when the steel sheets are exposed to chemicals or abrasive substances. Regular maintenance and inspections play a crucial role in the prevention of rust and corrosion on steel sheets. This involves surface cleaning, the removal of any debris or contaminants, and the repair of any damaged or worn-out coatings. By adhering to these preventive measures, steel sheets can remain shielded and maintain their structural integrity for an extended lifespan.

- Q: Can steel sheets be bent or shaped?

- Yes, steel sheets can be bent or shaped using various techniques such as rolling, pressing, or folding.

- Q: Can the steel sheets be easily drilled or machined?

- Steel sheets can be drilled or machined with ease. The versatility of steel allows for easy manipulation using a range of tools and techniques. Drilling and machining steel sheets is a widely practiced method in industries like construction, manufacturing, and engineering. By employing the appropriate equipment and expertise, one can create holes, mold the material, or attain precise dimensions required for a specific purpose.

- Q: What are the common lengths of steel sheets?

- Common lengths of steel sheets can vary depending on the specific application and industry requirements. However, some commonly available lengths include 8 feet (2.44 meters), 10 feet (3.05 meters), and 12 feet (3.66 meters).

- Q: What are the different storage methods for steel sheets?

- There are several different storage methods for steel sheets, depending on the specific requirements and space availability. Here are some commonly used storage methods: 1. Flat storage: This is the most basic method where steel sheets are stored horizontally on a flat surface, such as the floor or metal racks. It is suitable for small quantities or when the sheets are not too heavy. 2. Vertical storage: Steel sheets can be stored vertically by placing them against a wall or by using specially designed vertical racks. This method saves floor space and allows for easy access and identification of different sheet sizes. 3. Cantilever racks: These racks have horizontal arms that extend outward from a vertical column, providing support for steel sheets placed on them. Cantilever racks are ideal for storing long and heavy steel sheets, as they allow for easy loading and unloading using forklifts or cranes. 4. Roll-out racks: These racks have rollers or ball bearings that allow steel sheets to be easily rolled in and out, similar to a drawer. Roll-out racks are useful when frequent access to different sheets is required, as they provide good visibility and easy retrieval. 5. A-frame racks: A-frame racks have angled arms that support steel sheets in a slanted position, resembling the letter "A." This method is suitable for storing large quantities of steel sheets and provides easy access while keeping them organized. 6. Automated storage and retrieval systems (AS/RS): These systems use computer-controlled mechanisms to automatically store and retrieve steel sheets. AS/RS can be designed as vertical lift modules or robotic systems, maximizing storage capacity and efficiency. It is important to consider factors such as sheet size, weight, accessibility, and safety when choosing the appropriate storage method for steel sheets. Adequate measures should also be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially affect their quality.

- Q: How are steel sheets manufactured?

- Steel sheets are manufactured through a process called hot rolling. This involves heating the steel billets, passing them through multiple rollers to reduce the thickness, and then cooling them to create flat sheets.

- Q: Can steel sheets be used for toolboxes and cabinets?

- Yes, steel sheets can be used for toolboxes and cabinets. Steel is a durable and strong material, making it suitable for creating sturdy toolboxes and cabinets that can withstand heavy use and provide ample storage space.

- Q: Are the steel sheets resistant to oil or grease?

- Yes, steel sheets are generally resistant to oil and grease.

- Q: Can steel sheets be used in the construction industry?

- Yes, steel sheets can be used in the construction industry. They are commonly used for various applications such as roofing, siding, flooring, and structural components due to their strength, durability, and resistance to fire and corrosion.

- Q: What is the cost of steel sheets compared to other metals?

- The cost of steel sheets can vary depending on factors such as the type of steel, thickness, and market conditions. However, generally speaking, steel sheets tend to be more cost-effective compared to many other metals due to the abundance of iron ore and efficient manufacturing processes.

Send your message to us

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords