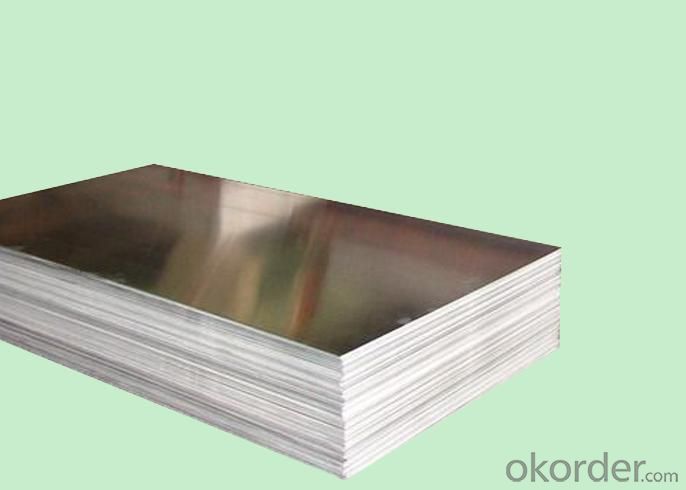

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Sheet

1. Chemical composition of AISI 304 Stainless Steel Sheet

C | Si | Mn | P | S | Ni | Cr |

max0.08 | max1.00 | max2.00 | max0.045 | max0.03 | 8.00-10.50 | 18.00-20.00 |

2. Mechanical properties of AISI 304 Stainless Steel Sheet

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

3. Standard of AISI 304 Stainless Steel Sheet : AISI, ASTM, GB, EN, DIN, JIS

4. Surface of AISI 304 Stainless Steel Sheet : 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of AISI 304 Stainless Steel Sheet :

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of AISI 304 Stainless Steel Sheet : 1 Ton

7. Payment terms of AISI 304 Stainless Steel Sheet : T/T or L/C

8. Packing of AISI 304 Stainless Steel Sheet : Seaworthy package with wooden or Iron pallets with the paper and the steel strip,

or as customers' request.

9. Delivery time of AISI 304 Stainless Steel Sheet : Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q: Are stainless steel strips suitable for decorative trim?

- Yes, stainless steel strips are suitable for decorative trim. They are durable, resistant to corrosion, and have a sleek and modern appearance, making them a popular choice for adding a touch of elegance and sophistication to various surfaces and areas.

- Q: Can stainless steel strips be used in oil and gas industries?

- Yes, stainless steel strips can be used in oil and gas industries. Stainless steel is known for its excellent resistance to corrosion, high strength, and durability, making it an ideal material for various applications in the oil and gas sector. Stainless steel strips can be used for fabricating pipes, tubes, fittings, valves, heat exchangers, and other components that are exposed to harsh operating conditions, including corrosive environments, high temperatures, and high pressures. Additionally, stainless steel offers good weldability and formability, allowing for easy fabrication and installation in oil and gas facilities. Overall, stainless steel strips provide the necessary reliability and performance required in the oil and gas industry.

- Q: Are 111 stainless steel strips suitable for outdoor applications?

- Yes, 111 stainless steel strips are suitable for outdoor applications.

- Q: Are stainless steel strips suitable for water treatment plants?

- Yes, stainless steel strips are suitable for water treatment plants. Stainless steel is a corrosion-resistant material that can withstand exposure to water and various chemicals commonly used in water treatment processes. It offers excellent durability and longevity, making it a reliable choice for infrastructure in water treatment plants. Stainless steel strips can be used in various applications within these plants, such as piping, tanks, valves, and other equipment. Additionally, stainless steel is hygienic and easy to clean, which is essential in maintaining water quality. Overall, stainless steel strips are a suitable and beneficial material for use in water treatment plants.

- Q: Why does the stainless steel after processing have magnetism?

- In addition, 304 stainless steel after cold processing, the structure of the structure will also change to martensite, and the greater the deformation degree of cold work, the more martensitic transformation, the greater the magnetic properties of steel. The stable austenite structure can be recovered by high temperature solution treatment so as to eliminate magnetism.

- Q: What are the common finishes available for stainless steel strips?

- There are several common finishes available for stainless steel strips. The most commonly used finishes include: 1. Mill Finish: This is the basic finish that stainless steel strips come in after production. It has a dull, matte appearance and is typically used for industrial applications where aesthetics are not a priority. 2. Brushed Finish: Also known as satin finish, this finish is achieved by brushing the stainless steel strips with an abrasive material to create a consistent, unidirectional pattern. It has a smooth and lustrous appearance, making it suitable for decorative applications such as kitchen appliances or architectural elements. 3. Mirror Finish: As the name suggests, this finish provides a highly reflective surface similar to a mirror. It is achieved by polishing the stainless steel strips with progressively finer grits until a smooth and shiny surface is obtained. Mirror finish is commonly used in decorative applications where a high-end, luxurious appearance is desired. 4. Embossed Finish: This finish involves creating a textured pattern on the surface of the stainless steel strips. It can be achieved through processes like stamping or rolling, resulting in raised or recessed patterns. Embossed finishes are often used to add visual interest and improve grip in applications such as elevator doors or decorative panels. 5. Patterned Finish: Similar to embossed finishes, patterned finishes involve creating a decorative pattern on the surface of the stainless steel strips. This can be achieved through processes like etching or laser engraving, allowing for intricate and customized designs. Patterned finishes are commonly used in architectural and interior design applications. 6. Colored Finish: Stainless steel strips can also be coated or painted to achieve various colors. This is typically done through processes like powder coating or electroplating, allowing for a wide range of colors and finishes to match specific design requirements. Overall, the choice of finish for stainless steel strips depends on the intended application and the desired aesthetic appearance. Each finish has its own unique characteristics and advantages, making stainless steel a versatile material for various industries.

- Q: How do stainless steel strips resist stress corrosion cracking in chloride environments?

- Stainless steel strips are highly resistant to stress corrosion cracking in chloride environments due to their inherent properties and specific alloy composition. The primary factors that contribute to this resistance include the presence of chromium, molybdenum, and nickel in the stainless steel alloy. Chromium is the main component responsible for the corrosion resistance of stainless steel. When exposed to chloride ions in the environment, a passive oxide layer of chromium oxide forms on the surface of the stainless steel strips. This oxide layer acts as a protective barrier, preventing the penetration of chloride ions and reducing the likelihood of stress corrosion cracking. Molybdenum is another crucial element in stainless steel alloys that enhances their resistance to stress corrosion cracking in chloride environments. It provides additional protection by increasing the material's resistance to pitting and crevice corrosion, which can be precursors to stress corrosion cracking. The presence of molybdenum also improves the overall strength and durability of the stainless steel strips. Nickel is an alloying element that further enhances the resistance of stainless steel strips to stress corrosion cracking. It increases the material's ability to withstand the corrosive effects of chloride ions, thereby minimizing the risk of crack initiation and propagation. In addition to these alloying elements, the specific composition and microstructure of the stainless steel strips play a crucial role in their resistance to stress corrosion cracking. The selection of an appropriate stainless steel grade, such as 316 or 904L, with a higher content of chromium, molybdenum, and nickel, ensures optimal resistance to chloride-induced corrosion. Furthermore, proper fabrication processes and surface treatments, such as passivation, can help enhance the corrosion resistance of stainless steel strips in chloride environments. Passivation involves the removal of iron contaminants from the surface and the formation of a more uniform and protective chromium oxide layer, further reducing the risk of stress corrosion cracking. Overall, stainless steel strips resist stress corrosion cracking in chloride environments due to the synergistic effects of chromium, molybdenum, and nickel, as well as their specific alloy composition, microstructure, and surface treatments. These factors collectively contribute to the exceptional corrosion resistance of stainless steel, making it a preferred choice for various industries, including marine, chemical, and oil and gas.

- Q: How do you remove scratches from stainless steel strips?

- To remove scratches from stainless steel strips, you can try a few methods: 1. Start by cleaning the surface with warm soapy water and a soft cloth. This will help remove any dirt or grime that may be masking the scratches. 2. Use a non-abrasive stainless steel cleaner or a mixture of baking soda and water. Apply the cleaner to a soft cloth and gently rub it onto the scratched area in a circular motion. Be sure to follow the grain of the stainless steel to avoid further damage. 3. For deeper scratches, you can use a stainless steel scratch remover or a metal polishing compound. Apply a small amount of the product onto a clean cloth and rub it into the scratch using a circular motion. Continue rubbing until the scratch fades or disappears. Make sure to wipe off any excess product and rinse the area with water. 4. Another option is to use a fine-grit sandpaper or a stainless steel polishing pad. Start with a lower grit sandpaper (around 400) and gently rub it over the scratch in the direction of the grain. Gradually move to higher grit sandpaper (800, 1000) for a smoother finish. Remember to clean the surface afterwards to remove any residue. 5. If the scratches are too deep or extensive, it may be necessary to hire a professional to repair or replace the stainless steel strips. Remember to always test any cleaning or polishing method on a small, inconspicuous area first to ensure it doesn't cause any damage.

- Q: How do stainless steel strips perform in high-pressure environments?

- Stainless steel strips are known for their exceptional performance in high-pressure environments. These strips are commonly used in industries such as oil and gas, chemical processing, and power generation, where they are exposed to extreme pressures and temperatures. One of the key advantages of stainless steel strips is their high strength and resistance to deformation. They can withstand the intense pressure exerted on them without distorting or losing their structural integrity. This makes them ideal for applications where there is a need for reliable and durable materials. Moreover, stainless steel strips have excellent corrosion resistance properties, especially when alloyed with elements such as chromium and nickel. This protects them from the harmful effects of high-pressure environments, which often involve exposure to corrosive substances, such as acids or salts. The resistance to corrosion ensures that the strips can maintain their performance and structural strength over time. Another important feature of stainless steel strips is their ability to withstand high temperatures. They have a high melting point and can handle extreme heat without deforming or weakening. This makes them suitable for applications where high temperatures are involved, such as in heat exchangers or boilers. Furthermore, stainless steel strips offer excellent fatigue resistance, which means they can withstand repeated cycles of pressure fluctuations without cracking or failing. This is crucial in high-pressure environments where the material is subjected to constant stress and strain. Overall, stainless steel strips are highly reliable and perform exceptionally well in high-pressure environments. Their strength, corrosion resistance, heat resistance, and fatigue resistance make them a preferred choice for various industries where reliability and performance are critical.

- Q: Can stainless steel strips be used in architectural façade systems?

- Architectural façade systems can incorporate stainless steel strips, known for their durability and resistance to corrosion. This material is well-suited for exterior applications, including architectural façades, due to its high durability and corrosion resistance. By utilizing stainless steel strips, architects can achieve sleek and modern designs, enhancing the aesthetic appeal of buildings. Moreover, stainless steel provides exceptional weather resistance and demands minimal maintenance, making it a favored choice among architects and designers when crafting visually captivating and enduring façade systems.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords