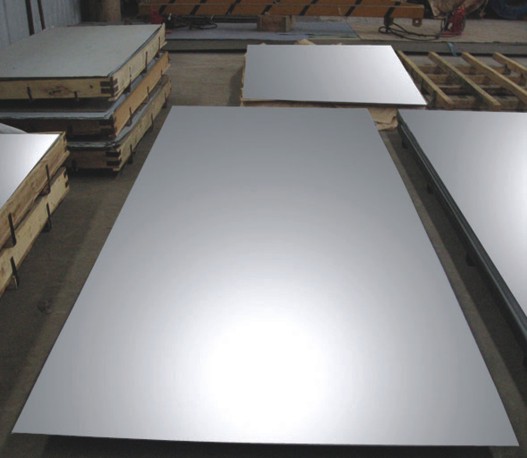

Stainless Steel Sheet 0.6mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Introduction of Stainless Steel Sheet 0.6mmx1220mmx2440mm: Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on. Loading Quantity of Stainless Steel Sheet 0.6mmx1220mmx2440mm: 25 Tons/20FCL. Grade of Stainless Steel Sheet 0.6mmx1220mmx2440mm: 201, 306, 316 Etc. Delivery Time of Stainless Steel Sheet 0.6mmx1220mmx2440mm: 20 days Per Container. Application of Stainless Steel Sheet 0.6mmx1220mmx2440mm: FAQ Q: CAN YOU PROVIDE MILL TEST CERTIFICATE? A: YES! Mill Test Certificate for Stainless Steel Sheet 0.6mmx1220mmx2440mm are available. Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)? A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality. Q: HOW TO GET A SAMPLE? A: FREE samples for Stainless Steel Sheet 0.6mmx1220mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

Finish Thickness Characteristics Applications No. 1 3.0mm~50.0mm Finished by hot-rolling, annealing and pickling, characterized by white pickled surface Chemical industry equipment, Industrial tanks No. 2B 0.3mm~6.0mm Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface General Application Medical Instruments,Tableware No. BA (Bright Annealed) 0.5mm~2.0mm Bright heat treatment after cold rolling Kitchen utensil, kitchen ware,architectural purpose No. 4 0.4mm~3.0mm Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes Milk & Food processing acilities, Hospital Equipment, Bath-tub HL(Hair Line) 0.4mm~3.0mm Finished by continuous linear polishing Architectural purposes, escalators, kitchen ware vehicles

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids.

- Q: How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, it is important to keep them clean and dry. Regularly clean the sheets with mild soap and water, and avoid using abrasive cleaners or scrubbing tools that can damage the protective layer. Additionally, ensure the sheets are completely dry after cleaning to prevent moisture accumulation. Applying a coat of mineral oil or a stainless steel cleaner can also help create a barrier against rust.

- Q: Can stainless steel sheets be used for elevator ceilings?

- Yes, stainless steel sheets can be used for elevator ceilings. Stainless steel is a durable and visually appealing material that is often used in elevators due to its resistance to corrosion, easy maintenance, and modern aesthetic. It provides a sleek and polished look to elevator ceilings and can enhance the overall design of the elevator interior.

- Q: What's the drill for stainless steel?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: Can stainless steel sheets be used for countertops or backsplashes?

- Yes, stainless steel sheets can be used for countertops and backsplashes. Stainless steel is a durable and hygienic material that is resistant to stains, heat, and corrosion, making it a popular choice for kitchen surfaces.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Indeed, swimming pool construction can utilize stainless steel sheets. Stainless steel, being a robust and corrosion-resistant material, proves to be an exceptional selection for pool construction. Its ability to endure chemicals and withstand the harsh swimming pool conditions, such as exposure to chlorine and saltwater, is highly commendable. Moreover, stainless steel sheets are effortless to clean and maintain, rendering them a popular choice for both residential and commercial swimming pools. Additionally, stainless steel adds a touch of sophistication and modernity, ultimately enhancing the pool's overall appearance. However, it is crucial to guarantee the usage of high-quality stainless steel sheets that meet industry standards to ensure prolonged performance and safety.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Absolutely, kitchen countertops can indeed be made from stainless steel sheets. The reason stainless steel is such a widely favored option for kitchen countertops is because of its exceptional durability, heat resistance, and hygienic qualities. It possesses a remarkable ability to ward off stains, corrosion, and rust, rendering it an ideal material for high-traffic areas, such as the kitchen. Moreover, stainless steel countertops are effortlessly cleaned and maintained, making them an extremely practical choice for bustling kitchens. Furthermore, the inclusion of stainless steel lends a polished and cutting-edge appearance to the kitchen, rendering it an exceedingly popular choice for both contemporary and industrial-style kitchens.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets require special handling during installation to ensure their proper installation and to prevent damage. Some important considerations include using proper lifting equipment, ensuring a clean and dry surface, avoiding contact with other metals to prevent galvanic corrosion, and following the manufacturer's guidelines for installation and maintenance.

- Q: How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, there are several measures that can be taken: 1. Proper alloy selection: Choosing the right grade of stainless steel with high resistance to corrosion is crucial. Grades such as 316 and 904L are known for their excellent resistance to pitting corrosion. 2. Passivation: Stainless steel sheets should be passivated after fabrication to remove any free iron or contaminants on the surface. Passivation involves treating the sheets with an acid solution, followed by a thorough rinse and drying. This helps to restore the protective chromium oxide layer on the surface, enhancing corrosion resistance. 3. Regular cleaning and maintenance: Stainless steel sheets should be cleaned regularly to remove any dirt, debris, or contaminants that can lead to pitting corrosion. Mild soap, water, and a soft cloth or sponge can be used for routine cleaning. Harsh or abrasive cleaners should be avoided. 4. Avoid exposure to aggressive environments: Stainless steel sheets should be protected from exposure to chemicals, chlorides, acids, and other corrosive substances. If such exposure is unavoidable, proper measures like the use of protective coatings or barriers should be implemented. 5. Avoid stagnant conditions: Pitting corrosion is often accelerated in stagnant or low-flow conditions where oxygen levels are depleted. Ensuring proper ventilation and circulation of air or fluids can help prevent pitting corrosion on stainless steel sheets. 6. Regular inspection and maintenance: Periodic visual inspection and monitoring of stainless steel sheets can help identify any early signs of pitting corrosion. If any pitting is noticed, immediate action should be taken to address the issue, such as applying a suitable corrosion inhibitor or protective coating. By following these preventive measures, it is possible to minimize the risk of pitting corrosion on stainless steel sheets, ensuring their long-term durability and performance.

- Q: What are the different types of embossed finishes available for stainless steel sheets?

- There are several different types of embossed finishes available for stainless steel sheets. Some of the most common ones include: 1. Diamond pattern: This is one of the most popular embossed finishes for stainless steel sheets. It features a raised diamond pattern that adds a decorative touch to the surface. 2. Linen pattern: The linen embossed finish creates a textured surface that resembles the look and feel of linen fabric. It adds depth and visual interest to the stainless steel sheet. 3. Leather pattern: The leather embossed finish is designed to mimic the look of genuine leather. It creates a textured surface that adds a unique and stylish touch to the stainless steel sheet. 4. Bead pattern: The bead embossed finish features a raised, rounded pattern that resembles beads. This finish adds a subtle decorative element to the stainless steel sheet. 5. Checker pattern: The checker embossed finish consists of raised squares or rectangles arranged in a checkerboard pattern. This finish adds a modern and stylish look to the stainless steel sheet. 6. Hammered pattern: The hammered embossed finish creates a textured surface that resembles the marks left by a hammer. It adds a rustic and handcrafted aesthetic to the stainless steel sheet. These are just a few examples of the different types of embossed finishes available for stainless steel sheets. Each finish offers a unique look and texture, allowing you to choose the one that best suits your design preferences and application requirements.

Send your message to us

Stainless Steel Sheet 0.6mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords