16g Stainless Steel Sheet

16g Stainless Steel Sheet Related Searches

16 Gauge Stainless Steel Sheet 16g Stainless Steel Wire 16 Gauge Sheet Steel 16ga Stainless Steel Thickness 16 Gauge Stainless Steel 1 8 Stainless Steel Sheet 316 Stainless Steel Sheet 20 Gauge Stainless Steel Sheet Sheet Of Stainless Steel 16 Gauge Stainless Steel Wire Stainless Steel 20 Gauge Sheet Thin Stainless Steel Sheets Stainless Steel 16 Gauge Wire 16 Gage Sheet Metal Black Stainless Steel Sheet 1/8 Stainless Steel Sheet 4 X 8 Sheet Of Stainless Steel 3 16 Stainless Steel 4x8 Sheet Of Stainless Steel 4x8 Stainless Steel Sheet Thin Sheet Stainless Steel Stainless Steel 4x8 Sheet Stainless Steel Sheets Price Steel Mesh Sheet Stainless Steel 4x8 Sheets Stainless Steel Sheet Price Stainless Steel Sheeting 14 Gauge Aluminum Sheet Stainless Steel Sheets 4x8 18 Gauge Aluminum Sheet16g Stainless Steel Sheet Supplier & Manufacturer from China

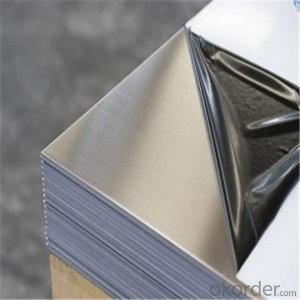

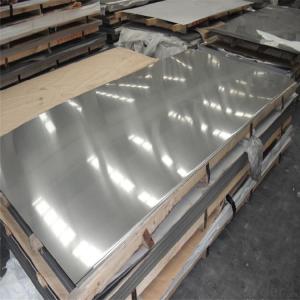

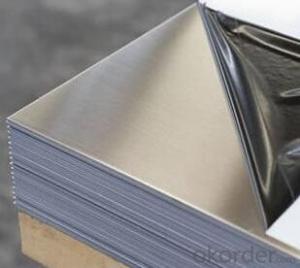

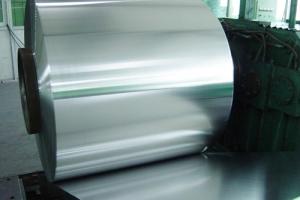

16g Stainless Steel Sheet is a versatile and durable material made from 16-gauge stainless steel, known for its corrosion resistance and strength. It is widely used in various industries, including construction, automotive, and food processing, due to its ability to withstand harsh environments and maintain its appearance over time. This product is particularly popular for applications such as kitchen equipment, architectural facades, and industrial machinery where both functionality and aesthetics are essential.The 16g Stainless Steel Sheet is utilized in numerous scenarios where its properties of durability and resistance to corrosion are highly valued. It is often chosen for its ability to maintain a sleek, modern appearance while providing the necessary strength and longevity required in demanding applications. Whether it's for use in the fabrication of commercial kitchen appliances or as a component in heavy machinery, this stainless steel sheet offers a reliable solution that stands up to the test of time.

Okorder.com is a leading wholesale supplier of 16g Stainless Steel Sheet, boasting a large inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that businesses have access to the materials they require to complete their projects successfully. By offering a comprehensive range of stainless steel sheets, including the 16g variety, Okorder.com has established itself as a go-to source for businesses seeking reliable and high-quality products.

Hot Products