Hot Sale High Quality 16Mo3 Steel Plate from Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 16Mo3 Steel Plate:

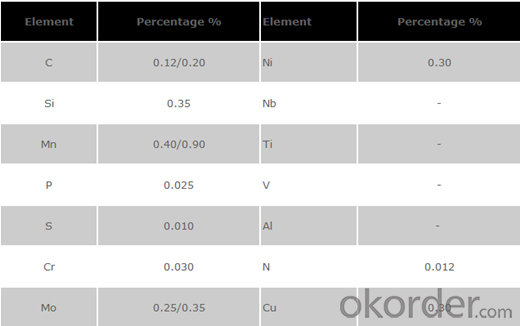

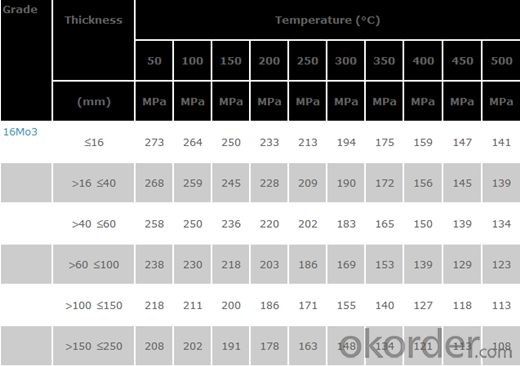

16Mo3 is a EN10028 specified pressure vessel grade chrome molybdenum steel alloy for use in elevated working temperatures. 16Mo3 is used as weldable steel in the fabrication of industrial boilers and steel pressurized vessels found in the oil, gas and chemical industry. Due to the materials chrome and molybdenum content, 16Mo3 has excellent heat resistance and corrosion resistant characteristics.

2、Main Feature of the 16Mo3 Steel Plate:

• High manufacturing accuracy

• High strength

• Wide Market in Middle East, South Asia, Iran, Europe and Russia

3、16Mo3 Steel Plate images:

4、16Mo3 Steel Plate Specification:

| Type: | 16Mo3 steel plate |

| Grade: | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

| Thickness: | 1.8-100mm |

| Width: | 1000-2500mm |

| Length: | 2000-12000mm as request |

| Certification: | API&ASTM Standard |

| Delivery Detail: | 15-20days after deposit received or as customer's request |

| Mill: | qualified steel mill in China |

| Service: | OEM Factroy |

5、FAQ of 16Mo3 Steel Plate:

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How can we receive more information?

You can contact us with Email or just call us directly but on weekend our information service is not available.

- Q: What is the average thickness tolerance for steel sheets?

- The specific grade and manufacturing process can cause the average thickness tolerance of steel sheets to vary. Nonetheless, the industry standard for cold-rolled steel sheets is typically ±0.005 inches (0.13 mm) for sheets up to 36 inches wide, and ±0.010 inches (0.25 mm) for sheets wider than 36 inches. In the case of hot-rolled steel sheets, the average tolerance is usually higher and ranges from ±0.010 inches to ±0.060 inches (0.25 mm to 1.52 mm) depending on the sheet's thickness and width. It is worth noting that these values are averages, and manufacturers may establish their own tolerances based on customer demands and production capabilities.

- Q: Can steel sheets be formed into complex shapes?

- Various metalworking processes, including bending, rolling, stamping, and laser cutting, enable the formation of complex shapes using steel sheets. By manipulating and transforming the sheets, intricate and custom shapes can be achieved to fulfill specific design requirements. Steel's malleability and strength allow for the creation of complex shapes without compromising its structural integrity. These capabilities find extensive application in industries like automotive, aerospace, construction, and manufacturing, where the demand for precise and intricate components is high.

- Q: Can the steel sheets be bent or formed into different shapes?

- Yes, steel sheets can be bent or formed into different shapes using a variety of techniques such as pressing, rolling, or using specialized machinery like hydraulic brakes or metal forming tools.

- Q: What is the difference between a perforated and woven steel sheet?

- A perforated steel sheet is a metal sheet that has holes or perforations evenly distributed across its surface. These holes can be of various shapes and sizes, such as round, square, or slotted. Perforated steel sheets are commonly used in applications where airflow, visibility, or drainage is required, such as in architectural design, filtration systems, and acoustic panels. The main advantage of perforated steel sheets is their ability to provide these functionalities while still maintaining structural integrity. On the other hand, a woven steel sheet is a metal sheet that is made by interlacing steel wires together in a specific pattern. This interlacing creates a mesh-like structure, where the wires form a series of intersecting horizontal and vertical lines. Woven steel sheets are commonly used in applications that require strength, durability, and security, such as in fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their ability to provide a high level of strength and security due to the tightly interwoven wires. In summary, the main difference between a perforated and woven steel sheet lies in their respective structures and functionalities. Perforated steel sheets have evenly distributed holes across their surface, providing benefits such as airflow and visibility. Woven steel sheets, on the other hand, are made by interlacing steel wires together to form a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the application at hand.

- Q: Can steel sheets be used for making furniture?

- Certainly, furniture can be made using steel sheets. Steel, as a material, is highly versatile and offers numerous benefits in furniture construction. Its notable attributes include strength, durability, and the ability to withstand heavy loads. One can shape, weld, and fabricate steel sheets into various furniture pieces, ranging from tables and chairs to cabinets and bed frames. Moreover, steel furniture tends to exhibit resistance against rust and corrosion, making it suitable for both indoor and outdoor settings. Additionally, the sleek and modern aesthetic of steel effortlessly adds a contemporary flair to any given space.

- Q: How do you prevent rusting on steel sheets?

- To prevent rusting on steel sheets, there are various effective measures you can implement: 1. Implement Protective Coatings: Create a barrier between the steel surface and the surrounding environment by applying protective coatings like paint, enamel, or powder coating. These coatings act as shields that guard against moisture and oxygen, thus preventing rust formation. 2. Utilize Galvanization: Coat the steel sheets with a layer of zinc through the process of galvanization. Zinc is highly resistant to corrosion and serves as a sacrificial anode, safeguarding the steel underneath. This method is commonly employed for outdoor applications where steel is exposed to moisture and harsh weather conditions. 3. Ensure Proper Storage: It is vital to store steel sheets in a dry and well-ventilated area to prevent rust formation. Moisture and humidity play significant roles in rust development, so it is essential to keep the sheets away from damp or wet environments. Additionally, storing the sheets off the ground on pallets or racks can help avoid contact with moisture. 4. Practice Regular Cleaning and Maintenance: Consistently clean the steel sheets with mild detergent and water to eliminate dirt, debris, or corrosive substances that may lead to rusting. After cleaning, thoroughly dry the sheets to prevent moisture accumulation. 5. Employ VCI (Volatile Corrosion Inhibitor) Packaging: During storage or transportation, employ VCI packaging materials such as VCI paper or film to effectively prevent rust on steel sheets. VCI emits corrosion-inhibiting molecules that form a protective layer on the steel surface, thus preventing rust formation. 6. Avoid Water Contact: Steer clear of prolonged exposure of steel sheets to water or other corrosive liquids. If the sheets come into contact with water, it is essential to promptly and thoroughly dry them to prevent rusting. By adhering to these preventive measures, you can significantly mitigate the risk of rust formation on steel sheets, ensuring their long-term durability and performance.

- Q: Are the steel sheets suitable for water tank fabrication?

- Yes, steel sheets are suitable for water tank fabrication. Steel is a strong and durable material that can withstand the weight of water and provide structural support. It is also resistant to corrosion when properly coated or treated, ensuring that the water stored in the tank remains clean and uncontaminated. Additionally, steel sheets can be easily molded and shaped to meet specific design requirements for water tanks. Overall, steel sheets are a reliable and commonly used material for water tank fabrication.

- Q: Are steel sheets suitable for cold storage applications?

- Cold storage applications can benefit from the use of steel sheets. Steel, known for its durability and strength, can withstand the low temperatures typically required for cold storage. This material is resistant to corrosion and does not absorb moisture, making it ideal for maintaining the cold air within the storage area. In addition, steel sheets are easy to clean and sanitize, ensuring the hygiene and safety of stored items. With excellent insulation properties, steel helps maintain a consistent temperature within the cold storage facility. Furthermore, steel sheets can be customized and fabricated to meet specific size and shape requirements for cold storage. In conclusion, steel sheets provide a reliable and practical solution for cold storage needs.

- Q: What is the function of an automobile leaf spring?

- Spring: the multi length and unequal curvature of the folded plate. After installation ends naturally curved upward. When the impact force of the wheel face came when the steel plate deformation, play a buffer, damping effect

- Q: Are the steel sheets suitable for outdoor sculptures?

- Yes, steel sheets are suitable for outdoor sculptures. Steel is a durable and weather-resistant material, making it ideal for withstanding the elements in an outdoor environment. It is able to endure extreme temperatures, moisture, and UV radiation without deteriorating or losing its structural integrity. Additionally, steel sheets can be easily manipulated and shaped into various forms, allowing for endless possibilities in creating outdoor sculptures. Its strength and stability also make it capable of supporting larger and more intricate designs. Overall, steel sheets are a popular choice among artists and sculptors for creating outdoor sculptures due to their durability, versatility, and ability to withstand the harsh outdoor conditions.

Send your message to us

Hot Sale High Quality 16Mo3 Steel Plate from Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords