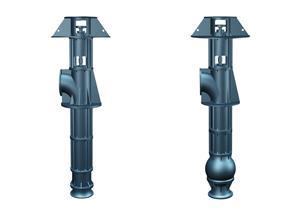

Vertical Mixed Flow Pump LX/LB/LT/LK Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description

LX, LB, LT, LK Series vertical mixed flow pumps are widely used in handling circulating water in large scale power stations and nuclear power stations, metallurgy, water supply & drainage of municipal facilities and farmlands as well as mining drainage. They are provided for delivering clear water , rainwater, sewage and seawater below 55℃.

Performance range

Capacity Q: 0.20~25m3/h

Head H: 3~60m

The pump of the above-mentioned range can be tested in our test center which is the largest in China.

Instruction of pump type

For example:80LK-20A / 80LB-20A / 80LX-20

80: Pump outlet diameter (inch)

L: Vertical mixed flow pump

T: Vertical mixed flow pump (impeller blades adjustable in operation)

K: Rotor can be pulled out

B: Rotor can not be pulled out

X: Outlet is under pump foundation

S: Outlet is above pump foundation

20: Rate head

A: Impeller after cutting.

Structure

*The pump is vertically installed with the inlet vertical downward and the outlet horizontal extending.

*The rotor parts have pull-out mode and non-pull-out mode. The impeller blades of type T pump can be adjustable in operation.

*The pump installation has two choices. One is single foundation: the pump and the motor are connected directly and mounted on one concrete foundation; the other is double foundation: the pump and the motor are mounted on separate concrete foundation.

*The seal usually uses packing seal.

*The intake sump of the pump can be wet pit or dry pit.

*The axial thrust of the pump is usually carried by the motor, but small pumps usually carried by the pump itself.

*The impeller of the pump is usually one stage and it can be designed to be multistage as requirements.

*The bearings of the pump can be rubber bearings or Thordon bearings, when the rubber bearings are used, the shaft protected by a set of shaft sleeves with pressure clear water for lubrication.

Material of main parts

Shaft: High-quality carbon steel.

Impeller: Cast iron / Cast steel / Stainless steel.

Other parts: Cast iron / welded steel plate.

Parts range

Pump, Motor, Foundation plate and Mounting resistant cushion.

- Q: 1998 Honda civic water pump plastic or metal inside (OEM)?

- nearly all honda water pumps are all metal construction...including this one.

- Q: I have 2004 Chevy Trailblazer V8 4x4 that the water pump went out on. Does anyone know how long it takes to change it and where it is located? The dealer wants $750.00 to fix it. I really don't want to get riped off.

- Well havnt taken one off of a trail blazer but they are all basic.except on transvers engines the kind that sitfrom right to left, get the book on it and follow the directions you can do it. It takes time and its kinda funky but you can do it. The only thing that concerns me is that you dont know where it is at. Hey why dont you call around some shops are price different. Was this a dearler price? California shops charge about 75 to 90.00 per hour. It would take about 2.5 to 3.5hours for the job plus the pump get a good one.

- Q: I think my water pump is going bad but figure id ask everyone to see what they thought. I leak coolant like the first 20 min i drive my truck and then it will seal itself up for the next day or two then start leaking again. It is getting leaked all over the belt and the fan is spraying it all around so you cant tell where exactly its coming from but i checked all the hoses and they are good and im pretty sure its not the radiator. Also, when it is leaking there is a loud whining noise when my trucks on and i heard that can be from the pump too.

- LOOK okorder on internet! WHAT SIZE IS ENGEIN HERE! FOur, five, six, eight yidner from WHAT COMPANY! NOBODY can answer thsi question for you without MORE DETAILS! THANX!

- Q: I recently took my 2002 Pontiac Grand Prix in for an oil change, and was told that my water pump has burst. I knew something happened the previous night because all of a sudden my car was overheating and when I opened the hood there was water everywhere, Anyways I am currently a single mom, working temp jobs while I look for something permanent. I can not afford the 350.00 to get it fixed. If I continue to drive the car am I looking at serious damage, He showed me how to fill the water tank (or whatever) so that the car will not be empty, But he says I need to get it fixed soon

- A okorder /

- Q: I live in a condo building -- 3 floors, 7 units. In our storage units (right below my unit) is a water pump that was hooked up with the intent of helping the water flow to the 3rd floor. Everytime the pump goes off, it rattles, then makes a loud noise when it kicks off. The developers created a drywall box that houses the pump, which is surrounded by isolation, but it doesn't seem like it helps the noise. The pump also rattles the pipes that connect directly to the pump.My question is -- is this rattling normal for a standard water pump? If so, is there anything I can do to help cut down on the noise? If this is rattling is not normal of the standard water pump, what would it cost to replace it with something decent?

- I do not know the kind of pump you are referring to. I will give my personal expertise. If it is a pump taking water from a tank, the piping might be loose, the knocking may be corrected with some air ventilation pipe. If it is pumping from a water tank: I suggest you look at a submersible pump capable of supplying water to 3rd floor. This kind of pump is less noisy. The noise at start, is the electric starter, and the noise at the end is when water returns and seals the stop valve. Also some air may be in the pipe, you need to purge the pump, as often as needed, try this first, and then the others. Good luck

- Q: I will be replacing my water pump tomorrow and my question is can I use copper spay gasket to spray on the water pump gasket?it this stuff good?99 ford explorer 4.0 ohv with 144k,mileshere is a pictures of the product.

- Sure, why not? Usually, the metal area when most water pumps are bolted too are cleaned with a scraper of some kind and old gasket matter is removed. That surface should be cleaned, flat, and free of irregularity. Most mechanics, if they use any kind of stickum - like contact cement from a tube, or the costlier, but not-needed specialty sealers, is applied to the pump surface so the gasket stays put and not move when installing the bolts. The glue does not do any actual sealing, just the fiber gasket will. None needs to be applied to the engine side that you scraped clean. Make sense to you? It's probably a good idea to service the cooling system with a non-caustic flush cleaner before hand -since all the coolant will come out during the change. Then add a additive that neutralizes acids with the new anti-freeze.

- Q: What is a variable frequency water pump? What's the difference between a variable frequency pump and an ordinary pump?

- In fact, the key to this problem is to figure out what is frequency conversion, why frequency conversion, know this problem, we can easily understand the difference between frequency converter pump and ordinary water pump.We often say that the frequency is a frequency conversion process of the motor, the frequency of the motor to change the motor speed, so as to achieve the water pump flow head technology parameters are adjusted to control the role of.Variable frequency water pump refers to the motor, variable frequency pump should be driven by variable frequency motor pumpFrequency conversion, that is, adjustable frequency, frequency conversion motor is able to adjust the speed, adjust the flow, to achieve the purpose of energy saving, but also start small current, maintenance advantages of small workload.Ordinary water pump is to use ordinary motors to drive water pump rotation, that is called the power frequency motor. Our daily use frequency 50Hz, can not speed. Water pump adjustment flow through the valve throttling to achieve the same, so it is not energy-saving. The fear of harm in Wei Di apps

- Q: $900 for a 96 neon but she says the water pump needs replaced.how much does it cost usually? is it even worth buying?

- While it is all apart the timing belt and tensioner should be replaced. It will cost several hundred to have it done. Neons don't get much older the 96, I would pay more like $500 for it. Make sure the head gasket is not leaking.

- Q: Hi, my water pump isn't working in my rover 400i V reg 99 model......does anyone know where under my bonet this is located and whether it's easy done at home?

- water pumps are never an easy fix. most the time you have to take the fan off, and the radiator as well so a person has room to work. MOST water pumps are in front of the motor, towards the bottom. If you follow your radiator hoses you will find it.

- Q: Engine problem 1999 Nissan Sentra 4 cyl Front Wheel Drive Automatic 165000 miles ---------------------------------------------------------------- I have a leaking water pump that has to be replaced. I am calling around getting prices and some people tell me that I have to do the timing chain at the same time and that will be a great deal more money. Can I just replace the water pump? It seems that the water pump only will be about 200.00 but both could be 500.00. Please help

- nissans are a pain in the @s$

Send your message to us

Vertical Mixed Flow Pump LX/LB/LT/LK Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords