Vertical Axial Flow Pump with top Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

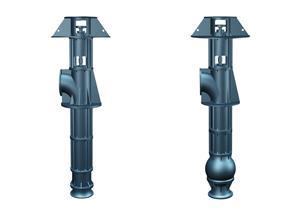

Vertical Axial Flow Pump with top Quality

Basic Info. of Vertical Axial Flow Pump with top Quality

Model NO.:ZLB

Performance:Wear Pump

Start Up:Electric Pump

Media:Sea Water Pump

Application:Submersible Pump

Type:Blade Pump

Material:Cast Iron

Power:Electric

Structure:Single-stage Pump

Theory:Axial Flow Pump

Assembly:Liquid Pumps

Industry:Fisheries Pump

Export Markets:Global

Product Description of Vertical Axial Flow Pump with top Quality

Performance Range:

Diameter: 250 ~ 2000mm

Capacity: 400 ~ 80000 m3/h

Head: ≤ 30 m

Description of Vertical Axial Flow Pump with top Quality

ZLB type axial flow pump is characterized by its large capacity, low head, etc. It can transport clean water whose temperature is less than 50º C, and also other liquids with physical and chemical properties similar to clean water.

Application Area of Vertical Axial Flow Pump with top Quality

Large-small type axial flow is widely used in agricultural irrigation, water supply and drainage for city, circulation water for thermal power plant, water level for dock, aquaculture, salt field pool and other hydraulic projects. Large type axial flow is mainly used in a large area of agricultural irrigation, interbasin water transfer and drainage for low-lying area, lake area.

Structural Characteristics of Vertical Axial Flow Pump with top Quality

ZL type axial flow pump is vertical structure, and is made up of pump casing and rotating parts.

(1) Pump casing contains inlet bellmouth, impeller parts, diffusor, rubber bearing, shaft, outlet elbow, packing seal etc.

(2) Impeller parts contain impeller seat, blade, compression nut. And static balance test shall be proceeded on the impeller before delivering. When user needs to adjust the installation angle of impeller, users can disassemble impeller parts, unscrew the compression nut, then rotate the impeller to make the blade base line align with the relative angle marks on the impeller seat, then tighten up the nut. If user has no special requirements when ordering, the blade installation angle is 0° When delivering. User can adjust on his own according to working performance curve and parameters.

(3) Pump shaft is made of high quality carbon structural steel(45steel), and surface of journal is plated with hard chrome to improve wear-resistant anti-cavitation performance. Radial support of shaft is born by two rubber bearings(upper and lower). Before starting, clean water shall be filled into the inlet pipe of stuffing box to lubricate the upper rubber bearing, stop it after the water is coming out of pump.

(4) Packing seal is used on the shaft hole of outlet elbow, made up of stuffing box, packing(Oil-immersed asbestos packing), packing gland. Overlook from the coupling end, the rotation direction of impeller is clockwise.

(5) Drive part: User shall confirm the drive type when ordering, according to using requirements and matched power.

Drive type: Direct drive device for vertical motor

(6) Pump outlet accessories are 30° Elbow, straight pipe, expansion joint, diffuser etc, and outlet valve is installed on the end. User can choose accessories according to the actual condition, and makes remark when ordering.

(7) The support of pump: Part weight of pump(Except the rotor part) is born by the foundation that supports pump casing, or born by the beam. Weight of drive device, motor weight and axial force(including weight of rotor part) are born by the floor that bears drive device.

FAQ

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

- Q: How much would it cost if I took it somewhere like midas?

- what variety of noise? additionally, what do you mean by skill of is it solid? They valuable looking autos IMO and that they are able to be solid if dealt with. do no longer assume to make diverse ability from the 420A engine although.

- Q: Ok, here's my problem. My parents bought this house a few years ago. No problems at first, but then during Hurricane Katrina, the basement started to flood from the heavy rains. Now whenever it rains, it floods. We have a half bath down there and the water would drain out in the shower drain. Now no water drains out, and we've already check the drain for clogs. It's clear. We currently have to bucket the water out.I'm looking for a good water pump to get them before I move out. I'm not sure if it has a sump pit or anything.We don't particularly care if we have to pump it out through a window or anything, as we have a pasture next to us. I just need something that could pump out the water when it rains. Preferably something not too expensive but that will still get the job done.Note: This is in Louisiana; lord knows what compelled the people who built this house to build a basement.Any suggestions/advice are much appreciated.

- hydromatic okorder /.. ~Honsell T- the reason he has water entering his basement is because he lives in Louisiana(or anywhere in the south really), which is at or BELOW sea level. you have to have serious waterproofing to not have leaks.

- Q: I'm trying to make water pump with solar energy. I need to have good water pump. Could you find good websites to find DC 12v water pump, or is there any place that I can get it?

- Good Gravy, Mon! Don't you know how to use 'SEARCH'?!? I just GOOGLED '12v dc water pump' and got a ca-jillion hits!

- Q: my nissan 1993 maxima SEthe AC is not cold at all this year it ran perfect the year beforecan the water pump pressure really affect the AC?how much should a new water pump cost for my car?

- You must know water pump is for cooling your motor ,by moving water around inside , AC has a pump or a compressor , Inside is a gas , under pressure the gas get cold when the cold lines are put in a space with a fan it makes cool air for you inside your car!!! All you may need is some more cooling gas for your AC pump

- Q: 1998 jeep cherokee water pump

- not quite a question here, what are you?

- Q: 4--6 inch deep well pump head? How much per hour out of water?.

- Best answerLift pump is the location of the outlet is high, such as wells 5 meters deep, you put the pumping pipe on the bottom, the pump is placed in the vicinity of well, then, the head is 5 meters, the water power how much you buy depends on the pump, the greater the power, the faster the water pumping. The greater the party...

- Q: i have a significant stream of water running out of the coolant return side of the engine under the coolant pipe on a 1997 caravan i will lose a gallon and then it stops until the engine heats up and of course more comes out with expansion

- You will have to remove the AC compressor, all of the drive belts, alternator bracket, power steering pump and bracket, motor mount, timing cover, and the timing belt. This job calls for 4.3 hours and I was able to do one in about 3. If you really want to attempt this yourself, let me know and I will give you detailed step by step instructions to do it, right down to the timing marks and what size each bolt is. If you have never done a water pump/timing belt on any car before, I strongly recommend you don't attempt this repair yourself. The 3.0 really isn't a bad one to do, if you have the tools and some mechanical knowledge and ability.

- Q: when i drove my truck after about 15 minutes i was parked and let my truck idle afetr about a minute of idling my truck stalled and when i turned it back of it was squeeking and made some noises for about ten seconds and then stopped. I noticed that the pully on my fan coming from the water pump was wobbling. my tempuratue was still normal what could cause this i am suspecting taht the bearings in my water pump went?

- you are likely right, usually the pump will leak a bit of water by this point, i did mine in my van and can be difficult cause you must seperate the fan. do not let this problem continue cause u will be broke down. replace the thermostat, bypass hose and check clutch and all hoses that are getting weak, and if possible do a power flush of the system..

- Q: House has bad mains pressure, so previous owner installed a quot;Holding Tankwhich stores water from the mains, before pumping it into the house for the internal tanks.However, after some recent plumbing work when the mains was turned off, it's running a little weird. The pump seems to be constantly running, although at a very low level, and some times when the taps/fawcets are opened, they seems to be nothing for up to 30 seconds (only air), and then the water rushes out. Same thing for toilet/WC cisterns..Any advice/pointers appreciated.CheersJM

- Sounds to me, like the pressure needs to be drained out of your storage tank..............good luck and have a nice new year.

- Q: It has a small leak that started this day and it has 60000 miles on it , also new or rebuilt . What is the appr. cost tohave a shop do it ?

- probably not that hard but if you want the best result take it to a shop. but if they dont do good you can always thke them to court lol

Send your message to us

Vertical Axial Flow Pump with top Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords