Swimming Pool Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Swimming Pool Water Pump

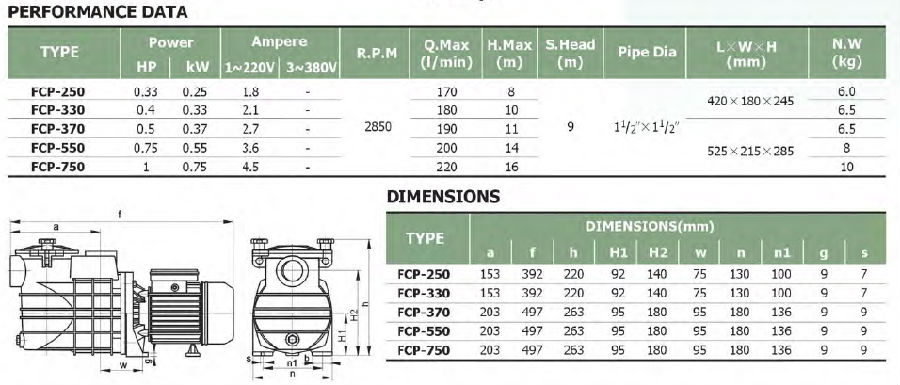

The swimming pool water pump is specially developed according to the operational features of the swimming pools both domestic and abroad and suitable to clean and remove dirts to keep the water in a good quility and to eliminate the in convenience to change the water often.

The pump is equipped with a spicial filtering system, which is fully mounted on a hand truck, where the process from sucking water to becoming standard water quility by filtering is finished.

Pump body:ABS

Impeller:ABS

Motor:Closed, Externally ventilated

Insulation class:B(Class F if required)

Protection class: IP44/IP55

Duty:Continuously rated

Mechanical seal:Φ12 ,Φ19ceramic steatite/graphite

Shaft:Stainless steel AISI 420

The normal power standard is 220v,50HZ,single phase

Three phase 220v/380v, 50HZ, 220V/460V, 60HZ

Single phase 230V, 240V, 127V,110V,115V/ 60HZ

- Q: my basement flooded and the water came in contact with the wiring on my water pump.Now the pump tries to turn on but shuts off without pumping any water.How do i get my pump pumping water again?

- sounds like not only did it come in contact withe wiring but also with the pump,when your working with electricity you need to be very careful and have the right tools to do the job with. to start this job you need a multi testing meter,this will let you check things like amp,volts,ohms,you know things that comes in contact with the pump and wiring,you didn't say what the voltage is on this pump,so first i'd find out what that is and make sure you have that going to the pump,then if so make sure the pump isn't froze or locked up,next go to the breaker box and locate the breaker for the pump,and test to see how many amps the pump is pulling when turned on.then find out if there is anything restricting the pump from doing its job,it may be something as simple as a run capacitor or even a shorted or burnt wire,but first make sure you have the correct voltage and amperage going to and coming out of the motor,once you get that taken care of you may need to prime the pump in order to get it pumping again

- Q: What I am trying to explain is that I took my vehicle to be serviced for a water pump. They installed it, but when I got my vehicle back, it started making this clicking noise. I took it back to be diagnosed and they came back to me saying that I need a new engine? (Before I took in my vehicle there was no clicking sound or problems, just the water pump.)Could this be the dealer trying to pull something for their mistake or what?

- It is hard to answer given the information given. What kind of car ? If your car has a waterpump that is turned by the timing belt, yes the shop could have messed up on the cam timing as they re-assembled after installing the pump. What is causing the clicking sound ? It could be a bent belt or any of a hundred things. Where do you hear the sound coming from ?

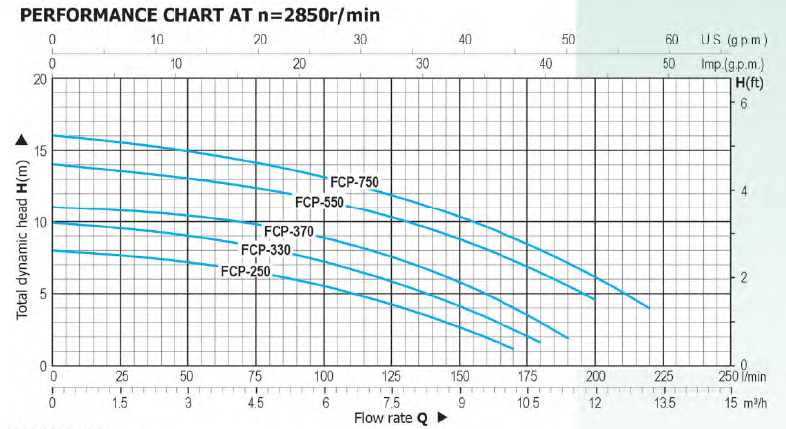

- Q: Pump head is too high what's the impact?

- Water pressure is too large, energy consumption is too high, you can choose near the flow of Yang Cheng

- Q: When did the pump start?

- The promotion of water is very important to human life and production. There are various ancient water appliances, such as Egypt's chain pump (seventeenth Century BC), China shadoof (seventeenth Century BC), Burton (Eleventh Century BC) and water (first Century ad). The famous spiral rods invented by Archimedes in the third Century BC can lift water to a few meters in a steady and continuous way, and the principle is still used by modern screw pumps.In 200 BC, the ancient Greek fire pump craftsmen invented by Kurt Siby Lucius is a kind of piston pump has the most original, the main components of a typical piston pump piston pump, but only after the steam engine was developed rapidly.1840~1850 years, the United States invented Worthington pump cylinder and steam cylinder opposite, the direct impact of the piston pump, marking the formation of modern piston pumps. Nineteenth Century was the climax of the development of piston pumps, which were already used in a variety of machines, such as water presses. However, with the rapid increase in water demand, from 1920s, the piston pumps with low speed and large flow were gradually replaced by high-speed centrifugal pumps and rotary pumps. But in the field of high pressure and small flow, reciprocating pump still occupies the main position, especially diaphragm pump and plunger pump have their own advantages and are used more and more.

- Q: What is the function of a submersible pump?

- Submersible pump motor and pump is directly connected with the water pump body into the water to work, it is suitable for the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects: mainly used for irrigation and plateau in the drinking water, but also for the city, factories, railways, mining and construction site the use of water supply and drainage.Characteristics of submersible pumps for well1 、 motor, water pump, submerged operation, safe and reliable.2, the well pipe and pump water pipe without special requirements (i.e.: steel tube wells, tube wells, Doi ash can be used).3, installation, use and maintenance of convenient, simple, small footprint, do not need to build pumping stations.The structure is simple, and the raw materials are saved.4, submersible pump conditions are appropriate, properly managed, and has a direct relationship with the service life.

- Q: water pump

- Flow? Head? suction pressure? Type of pump if that matters to you? You'll get better suggestions if you provide as much information as is relevant.

- Q: motor overheats but no leak. water just boils in resorvoir. is it hard to do it on my own?

- you may have air pocket.look for the perg valve to let the air out. if your water pump leaks it is bad

- Q: I have a 1995 Jeep Grand Cherokee 6 cyl while driving home the other day my check engine light came on ,then I noticed my battery was loosing its' charge ,then I noticed my temperature gauge rising very fast.I stoped to see what the problem was.The vehicle had over heated and the serpentine belt was partially off Iet it cool down then I put water in it and drove it home which was about a quarter of a mile.I noticed no problems with the fan hitting the water pump pully until I put the belt back on .My water pump pulley appears to be off line how do I fix this?

- your water pump bearing is probably worn out, unfortunately if this is the case replacing the water pump is the only option take the belt off again grab the fan if you can wiggle it forward and back its no good if its ok go to the belt tensioner, Its the next most likely culprit if it get out of line it will throw the whole thing out of whack good luck

- Q: My 1998 Dodge Dakota V6 heater only gets warm, I have replaced the thermostat. I have back flushed the heater core. The heater hose coming from near the thermostat gets hot, but the hose coming from the heater core going to the water pump only gets warm. The large hose coming from the thermostat is hot near the engine, but is only warm near the radiator. Is the water pump bad? If I open the radiator cap there is no signs of circulation. How do I check the water pump?Thanks,Gene

- to answer your question directly, you can check a water pump the same on any car. water pumps have whats called a weep hole there is a small hole that is designed to leak coolant when your water pump seal goes out. find the pump and see if there is a trail of white from this 'weep hole' then yes your pump is bad. if not, i dont know the layout of the hoses for your car so i couldnt diagnose it for sure. but check your water pump for the signs i gave you. its a tell tale sign

- Q: A tank is full of water. Find the work W required to pump the water out of the spout. (Use 9.8 for g and 3.14 for pi . Round your answer to three significant digits.)The tank is a spherical shape has a radius r= 6m and a spout height of h=2m.I really dont know how to start this problem correctly. Any help will be appreciated. Thanks!

- The pump will not have to work until the water drains by gravity to the level of the spout. Then, Work = Weight of water * Height of lift Find the distance, d, of the center of mass for the remaining water in the bottom 2 m of the sphere. The height of lift will then be 2m - d. The hardest part is finding the distance d to the center of mass. I don't remember how to do that.

Send your message to us

Swimming Pool Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords