Horizontal Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set unit

- Supply Capability:

- 1000 Sets Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

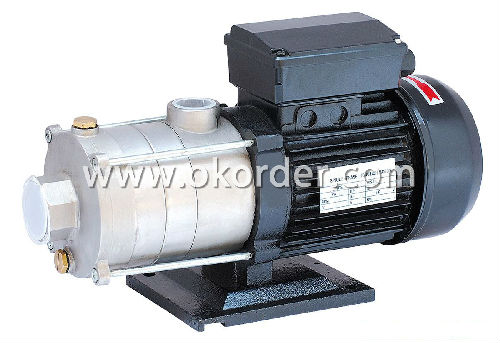

Horizontal Multistage Stainless Steel Centrifugal Pump

1. Applications of Horizontal Multistage Stainless Steel Centrifugal Pump

Cooling water system

Aquiculture

Domestic water supply

General industrial services

Washing

Environment protection

2. Performance Range of Horizontal Multistage Stainless Steel Centrifugal Pump

Capacity: Q up to 323/h

Head: H up to 88m

Temperature: T up to 110℃

Speed: n 2900rpm or 3500rpm

Power: P up to 55 kw *2

3. Standard Material of Horizontal Multistage Stainless Steel Centrifugal Pump

All the parts contact with liquid made of 304 stainless steel, 316 stainless steel on request. The pump head and suction & discharge can be made of cast iron on request too.

4. Description of Horizontal Multistage Stainless Steel Centrifugal Pump

Horizontal multistage design with stainless steel stamping welding impeller and diffuser, three different type for choice.

Single phase motor up to 2.2kw Class F and IP55 motor is standard

Standard supply for liquid temperature up to 70 degree, high temperature pump are available on request.

- Q: I noticed my car was quot;in the redand was about to overheat as i was driving, so at first I thought maybe i needed more coolant. I turned off my car and heard a fan noise under my engine for like a minute then it stopped. I checked the radiator and it was empty (no coolant) so i put water in there to get to the store to buy more coolant. By the time i bought some the water was already gone (this was only like 10 min) so I put the coolant in drove home again i noticed i was overheating, i checked again and all the coolant had leaked out too..it was all gone, that QUICK! So i asked a couple of men about it, and they say it sounds like it could be a hose or either a water pump. I don't know which it is, i can't drive it anywhere b/c it keeps overheating and i don't want to get it towed for $75 just to get a new hose. So is there a way i could tell what the problem is? Thanks!

- don,t start it but fill it up and take each hose and twist it some. if it,s a hose then it will start to leak. water pumps usually leak a lot when it,s running.

- Q: Where can I find a really good deal online for Spectre 4480 Water Pump Pulley Shim Kit

- You can purchase the Spectre 4480 Water Pump Pulley Shim Kit from OKorder for the heavily discounted price of $1.02. That's a full 83% or $4.97 off the list sticker price for this item. The product features: * Provides proper drive belt alignment with water pump * Fixed between the water pump pulley and drive flange * Shims pulley out 1/16, 1/8, or 3/16 for proper alignment * 3 shims per kit If you're interested in taking advantage of this great offer, visit the link below.

- Q: Give me a general intro. about submersible water pumps.

- they are sealed so that all electricl parts are water proofed

- Q: ok so im wondering if there is a water pump out there i can buy that automatically turns on when i turn the tap on. i looking for something thats strong enough to pump enough water to more than one taps at a time i.e kitchen tap, bathroom etc.

- See okorder /

- Q: We have just replced our hot water heater in our camper. When we turn on the water pump we hear it kick on and run. When we turn on a faucet water comes out then slowly goes away untill nothing comes out at all. It has been a year since we used the water tank, so its been full of air. The camper is pretty old, i dont know the specific date though. Could it be low water pressur? any help would be greatly appreciated.

- Check to see if the water pump has a filter on it. Could look like window screen or similar. Junk in that will fill up with pressure and cut the water off. If the pump stops running after a few seconds of flowing, its probably a filter. Once they get to a certain pressure, water valve opened or closed, they shut off to keep from burning up. If the water tank was left with some water in it, moss may have grown. Should flush it with some clorox and water. Check with a local dealer to see how much.

- Q: Got pump ready and will not pump water. Have tried all things suggested to prime but will not pump water

- You prime the gas with gasoline and the water pump is primed with water. The water pump needs a stop valve in the intake so you can add water and it will not run out. Once the impeller is full and the pump is running it should pump OK.

- Q: I am trying to replace my old water pump with a new one. I have the quot;special tooland everything but i just cant get the water pump to come loose at all. Any suggestions would be helpful Thanks

- When you mean it wont come loose, do you mean you cant break the bolts loose or is the pump stuck on the motor like glue? If the bolts are stuck, try spray them with penetrating oil and let it work in for about 30 mins. If the pump is stuck, use a narrow putty knif, gently tap in between the pump and the block, and pry it off, then clean the mating surface completely to ensure the new pump seals properly.

- Q: First the shop put in a heater core, but it was still leaking and overheating. Next they put in a water pump. Went to get it and now it wines really loud and the engine use to purr like a kitten, couldn't even tell it was running, now the engine shakes the whole car and it died one the way home but started again. The shop said the cam positioning needs reset again and on the way back to the shop it died again. So from leaking anti-freeze to now it vibrates, dies and wines really loud ! Any ideas what they did wrong ?

- Yea, this engine has the water pump that is driven off of the timing Chain, before removing the pump you have to install a holding tool to keep the timing gears synchronized, If the pump is removed first without installing the tool, the camshaft timing will be out of sync. and that's what probably happened. NOTE: This sounds like an unqualified shop to work on vehicles, if they can't trace a coolant leak! The first thing that should have been done is a CO2 test on the cooling system to see if the vehicle has any hidden head gasket issues. (Good luck)

- Q: I think my water pump is leaking and I want to replace it, but I can't figure out how to get the pulleys off. There is a large nut on the shaft that the pulleys are on, and I can't figure out how to remove it, or if the nut is attached to the shaft, and the entire shaft is supposed to come out, or how it's set up. Please help. Pictures would be great if possible. Thanks!

- take bolts and nuts off of fan and take off , might have to pry because of rust , corrosion . then take bolts out of the water pump , once all bolts are out , tap with rubber hammer or pry by hand, pump will separate , because of close quarters with radiator be careful not to damage radiator by accidentally hitting it

- Q: I have a 1997 ford ranger, during last week i noticed that the temperature started to go up, i noticed that the coolant recovery tank was empty so i added coolant and it fixed the problem, but a day later i noticed that the tank was empty again since it started to overheat again. This time i let the engine cool off and checked the radiator water levels and noticed it was dry with no water, so i added water and noticed that i was leaking from what it seems the water pump (im guessing its the water pump because is behind the engine fan, behind the belts, its hard to see), Does anyone have a possible explanation or suggestion of what i should do? Thank you i would really appreciate it.

- did u get a mechanic to do it? or do it your self? in case you had a mechanic do it, ask them to restoration it in case you had no issues past. must be thermostat, must be you dont have sufficient coolant in radiator or maybe suited coolant to water ratio. All i know is you ought to bleed out the radiator to do away with all air after water pump is taken off and placed back on, while you evaluate that would reason issues aswell. ok nicely you merely as much as date it, so i'm too, your mechanic sounds like a dumb ****, he ought to have bled air out of radiator, the actuality he informed you is strange, ought to have fixed it then and there. this is an significant step of adjusting water pump. If there is air in it, your radiator and water pump wont be rotating the water precise. tell him to restoration it and say you probably did your examine and you're actually not paying yet another cent!

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | 3,000-5,000 square meters |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Horizontal Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set unit

- Supply Capability:

- 1000 Sets Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords