Silicon Wafer Solar Panel - High Quality A Grade Mono晶Silicon 5V 18.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

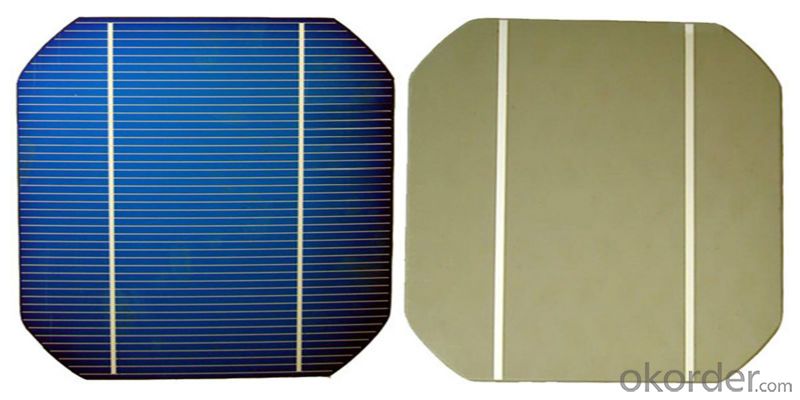

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

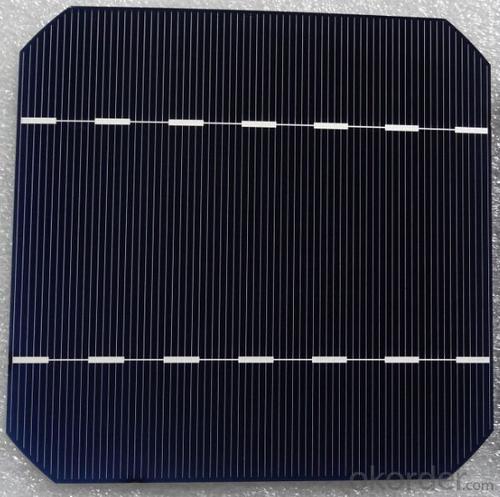

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: Are solar silicon wafers affected by electromagnetic interference (EMI)?

- Yes, solar silicon wafers can be affected by electromagnetic interference (EMI). EMI refers to the disruption caused by electromagnetic fields on electronic devices, and solar silicon wafers, being electronic components used in solar panels, are not immune to this interference. EMI can potentially impact the efficiency and performance of solar panels, leading to a decrease in power output. Therefore, it is important to consider EMI mitigation techniques during the design and installation of solar systems to minimize its impact on the silicon wafers and overall solar panel performance.

- Q: Can solar silicon wafers be used in solar-powered charging stations?

- Yes, solar silicon wafers can be used in solar-powered charging stations. These wafers are the primary component of solar cells, which convert sunlight into electricity. Solar-powered charging stations utilize solar cells to capture sunlight and generate electricity for charging various devices, making them a suitable choice for such applications.

- Q: Are there any environmental concerns with the production or disposal of solar silicon wafers?

- Yes, there are some environmental concerns associated with the production and disposal of solar silicon wafers. The production of silicon wafers involves energy-intensive processes and the use of hazardous chemicals, which can contribute to air and water pollution if not managed properly. Additionally, the mining of raw materials for silicon wafers can have negative impacts on ecosystems and communities. Proper disposal and recycling of silicon wafers are also important to prevent potential environmental harm. However, it is worth noting that compared to other energy sources, the environmental impact of solar silicon wafers is relatively lower, and advancements in technology and regulations continue to address these concerns.

- Q: What is the efficiency of a solar silicon wafer?

- The efficiency of a solar silicon wafer refers to its ability to convert sunlight into electricity. It is typically measured as a percentage of the incoming sunlight that is successfully converted into usable electrical energy. The efficiency can vary depending on various factors including the quality and composition of the silicon wafer, the manufacturing process, and the environmental conditions. Generally, the efficiency of a solar silicon wafer ranges from around 15% to 25%, with higher quality and more advanced technologies achieving higher efficiencies.

- Q: Are solar silicon wafers affected by electromagnetic interference?

- Yes, solar silicon wafers can be affected by electromagnetic interference. Electromagnetic interference can disrupt the operation and efficiency of solar panels by causing electrical noise, voltage fluctuations, and other performance issues. Therefore, proper shielding and grounding measures are necessary to minimize the impact of electromagnetic interference on solar silicon wafers and ensure optimal performance.

- Q: What is the impact of wafer resistivity on solar silicon wafer performance?

- The wafer resistivity of a solar silicon wafer has a significant impact on its performance. Lower resistivity allows for better conductivity and reduces the amount of energy lost as heat during the conversion process. This results in higher efficiency and improved overall performance of the solar cell. Additionally, low resistivity helps in minimizing the series resistance, enabling better current flow and maximizing the power output of the solar cell.

- Q: What is the role of solar silicon wafers in building-integrated photovoltaics?

- Solar silicon wafers play a crucial role in building-integrated photovoltaics (BIPV) as they are the key component used to convert sunlight into electricity. These wafers are made of high-purity silicon and are responsible for capturing and absorbing solar energy. They are then wired together to form solar cells, which are integrated into the building's architecture, such as rooftops or facades. The solar silicon wafers essentially act as the building blocks of BIPV systems, enabling the generation of clean and renewable energy directly from sunlight.

- Q: Can solar silicon wafers be used in water desalination systems?

- Yes, solar silicon wafers can be used in water desalination systems. These wafers can be utilized to generate electricity through photovoltaic cells, which can then power the desalination process. This approach, known as solar-powered desalination, offers a sustainable and environmentally-friendly solution to convert saltwater into freshwater using solar energy.

- Q: Can solar silicon wafers be used in aerospace applications?

- Yes, solar silicon wafers can be used in aerospace applications. They are commonly used in spacecraft and satellites to provide power through photovoltaic systems, converting solar energy into electricity.

- Q: What is the average reflectivity of a solar silicon wafer?

- The average reflectivity of a solar silicon wafer is typically around 30%.

Send your message to us

Silicon Wafer Solar Panel - High Quality A Grade Mono晶Silicon 5V 18.2% Solar Cell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords