40x26mm 4v 20ma Silicon Wafer Solar Cell for 800w Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

40X26MM 4V 20mA Solar Cell for 800W Solar Panel

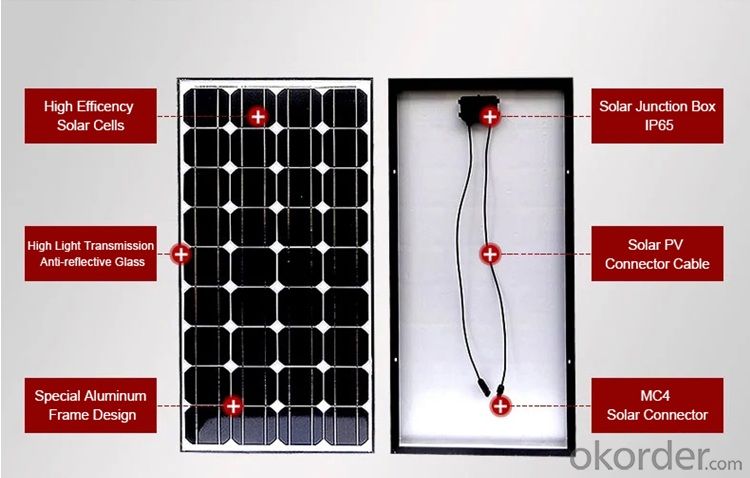

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Our Cells Special Features

1. High conversion efficiencies resulting in superior power output performance

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.For 156P poly cells with high efficiency in photovoltaic conversion 16.3%-17.5%.

6.Low inverse current, high shunt resistance and high dependability.

7. Our poly cells efficiency include: 17%-18%.

Product Pictures

Package

Typical package for one carton contains 1,200 cells. The cells are sealed in cell box every 100 pcs.

Gross weight per unit carton shall be around 16.4kg.

- Q: Are solar silicon wafers affected by electromagnetic interference (EMI)?

- Solar silicon wafers are not directly affected by electromagnetic interference (EMI). However, the performance of solar panels, which use these wafers, can be influenced by EMI. EMI can interfere with the proper functioning of the electrical components in a solar system, such as inverters or charge controllers, leading to reduced efficiency or even system failure. Therefore, while silicon wafers themselves are not affected, precautions need to be taken to minimize the impact of EMI on the overall solar power system.

- Q: Can solar silicon wafers be used in solar-powered transportation systems?

- Yes, solar silicon wafers can be used in solar-powered transportation systems. These wafers are commonly used in solar panels to convert sunlight into electricity. In solar-powered transportation systems, solar panels equipped with silicon wafers can be installed on vehicles, such as cars, boats, or drones, to harness solar energy and power their operations. This helps reduce reliance on traditional fuel sources and contributes to a more sustainable and environmentally friendly mode of transportation.

- Q: How do defects affect the efficiency of a solar silicon wafer?

- Defects in a solar silicon wafer can significantly affect its efficiency. These defects, such as impurities or structural abnormalities, can reduce the overall performance of the solar cell by hindering the flow of electrons or creating recombination centers. This leads to a decrease in the conversion of sunlight into electricity, resulting in a lower energy output. Therefore, minimizing defects is crucial for ensuring optimal efficiency in solar silicon wafers.

- Q: How do solar silicon wafers contribute to sustainable development goals?

- Solar silicon wafers contribute to sustainable development goals by enabling the production of clean and renewable energy. They are the key component in solar panels, which harness sunlight and convert it into electricity without emitting greenhouse gases or other harmful pollutants. By promoting the use of solar energy, silicon wafers help reduce reliance on fossil fuels, mitigate climate change, and support the transition towards a more sustainable and environmentally friendly energy system. Additionally, the manufacturing of solar silicon wafers can create jobs and stimulate economic growth, contributing to the goal of sustainable economic development.

- Q: How are solar silicon wafers protected from chemical damage?

- Solar silicon wafers are protected from chemical damage by applying a thin layer of protective coating. This coating acts as a barrier and prevents the contact between the wafer and potentially harmful chemicals. Additionally, the wafers are often stored in controlled environments to minimize exposure to chemicals and ensure their long-term durability.

- Q: Can solar silicon wafers be used in agricultural applications?

- Yes, solar silicon wafers can be used in agricultural applications. They can be integrated into solar panels to generate renewable electricity for various agricultural tasks, such as powering irrigation systems, livestock water pumps, or even electric fences. Additionally, solar technology can be utilized in greenhouses to provide supplemental lighting or heating, enhancing crop growth and productivity.

- Q: Can solar silicon wafers be used in other applications besides solar panels?

- Yes, solar silicon wafers can be used in other applications besides solar panels. They are also commonly used in the production of semiconductors, integrated circuits, and various electronic devices due to their excellent electrical properties and high purity.

- Q: How do solar silicon wafers handle extreme temperatures?

- Solar silicon wafers are designed to handle extreme temperatures quite well. They typically have a high melting point and can withstand temperatures ranging from extremely cold to very hot without significant damage. This is due to the high purity and crystalline structure of the silicon material used in their construction. Additionally, solar panels are often equipped with thermal management systems to dissipate excess heat and prevent any adverse effects on the wafers. Overall, solar silicon wafers are engineered to endure extreme temperature conditions and maintain their efficiency and reliability in various climates.

- Q: Can solar silicon wafers be used in solar-powered gadgets?

- Yes, solar silicon wafers can be used in solar-powered gadgets. These wafers are the primary component of solar cells, which convert sunlight into electricity. Solar panels and other solar-powered devices often utilize silicon wafers to harness solar energy and provide power for various gadgets and appliances.

- Q: How are solar silicon wafers affected by thermal annealing?

- Thermal annealing affects solar silicon wafers by improving their electrical properties and reducing defects. It helps to remove impurities and lattice defects, resulting in increased carrier mobility and enhanced solar cell performance. Additionally, annealing can enhance the crystalline structure of the wafers, leading to higher conversion efficiencies and improved overall quality of the solar cells.

Send your message to us

40x26mm 4v 20ma Silicon Wafer Solar Cell for 800w Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords