QB Series Peripheral Pumps with Brass Impeller

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application of QB Series Peripheral Pumps:

1> Clean Water without abrasive particles, non-aggressive liquid.

2> Domestic use.

3> In particular for delivering water in combination with small pressure sets and for irrigation.

4> Installed in enclosed places, or at least protected against inclement weather.

2. Operating conditions for QB Series Peripheral Pumps:

1> Suction lift up to 8m.

2> Liquid temperature up to +40℃

3> Ambient temperature up to +40℃。

4> Max. working pressure: 6bar.

3. Motor description of QB Series Peripheral Pumps:

1> 2-pole induction motor: 50Hz.

2> Insulation: Class B.

3> Protection: IP44.

4> With capacitor and thermal overload protection.

4. Material of QB Series Peripheral Pumps:

1> Pump body: Cast Iron.

2> Motor bracket: Aluminum.

3> Impeller: Brass.

4> Shaft with rotor: Stainless steel or CS45#

5> Mechanical seal: Ceramic-Graphite.

6> Copper Winding.

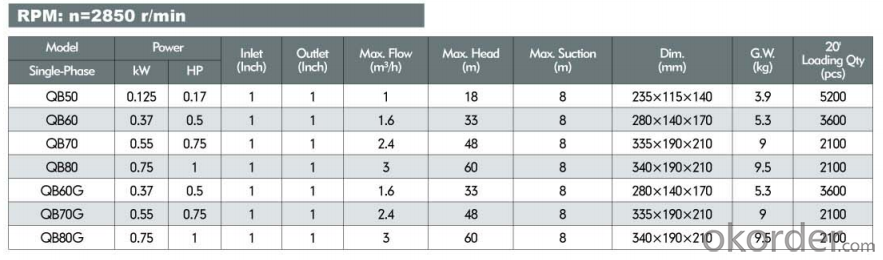

5. Detailed specification for QB Series Peripheral Pumps:

6. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q: Is the water lamp in the basement water pump fluorescent or waterproof?

- The ordinary pump houses are ordinary energy-saving lamps, but there is a glass shield outside of it which is waterproof...And they're all emergency lights!Like some large pump houses, they have riot lights...

- Q: 30kW what is the flow rate of the pump?

- There are many kinds of pumps, so it's difficult to answer you with a 30KW pump.

- Q: motor overheats but no leak. water just boils in resorvoir. is it hard to do it on my own?

- you may have air pocket.look for the perg valve to let the air out. if your water pump leaks it is bad

- Q: hiI have very low pressure only on the hot water in my kitchen sink. Cold water is fine. Can anyone recommend a water pump/power shower i can use for boosting my hot water in the kitchen sink tap?Ive already tested the faucet by swapping the water supplies.thanks

- Why do you need high pressure from the hot tap?

- Q: We had to have our well pump replaced yesterday, how long before the well settles down, and the water tastes like it used to?The company who replaced the pump told us when changing a pump it disturbs the well, and it would take time for everything to settle back into place. Thank you in advance for any and all suggestions.

- There are several things that contribute to settling down. If the pump was the only thing changed and not the depth it will no doubt take a couple of weeks. How far off the bottom of the vein of water does the pipe begin. Another factor is the type of soil. Sandy soil will generally run clear in a shorter period of time. If you have clay soil it will take longer. Another factor is the time of year. Given the fact that the water tables themselves change during the course of the year and depends on where you live. For example, If you've lived there for a few years you've probably noticed that you get more rust in your water in January and August. A not so good scenario would be that the water vein is changing or diminishing and that's why the pump went out in the first place. But, that is something the well people should have checked for. I would find out from them how deep the vein is and how far off bottom you are. That's something you should know anyway. Many if not all States require this information to be given to them and is recorded when a new well is bug. You can probably access the information on-line at your States website. However, I would still ask the well people for the information in case the information is not required by your state. This way they would have a better recollection of any particulars.

- Q: a picture of a water pump and its parts,picture of cross section of a water pump how water pump works

- Here's okorder /

- Q: Can I use Ultra Blue gasket maker on a water pump? The packaging is not labeled high heat.

- i could replace the gasket now particularly of attempting to recollect on end leak. reckoning on the place you reside, it somewhat is gonna get chilly authentic quickly. Wrenching in chilly climate sucks. And if the unique water pump has by no skill been replaced, you're able to think of approximately doing that while you have it aside, no count if it is not too costly for a clean/rebuilt pump. i be responsive to it could be in simple terms my success to take all of it aside, replace the gaskets, then have the water pump crap out 2 months later. DOH!

- Q: 90kw pump star delta start, in the end to use the circuit breaker, AC contactor (Star contactor, angle contactor), what kind of thermal relay?

- Imports, such as Schneider, press: plastic case press 250A, contactor select 115 of 2, 95 of 1 can.Domestic recommendations: Press: plastic case press 250A, contactor 160, 2, 115 of the 1 can.

- Q: Installed new water pump on 90 Jeep. Noticed antifreeze around the edges of the pump. Took it off, replaced with new gasket and sealer, but it seams to be leaking again.

- Take it off again and inspect the metal around the hole it is going in. Make sure there are no gouges or major damage. Besides that have a friend do the seal. I know what I am, doing and sometimes just a different method, or a new set of hands does the trick. That is probably the problem.

- Q: i was wondering how hard it would be to chancge a water pump in a 1997 chrysler sebring.

- Well, you will have to pull the belt for the car. Most likely will have to pull the alternator, power steering, ac compressor, and many other parts that are in the way. On an scale from one to ten and ten being the hardest, 4. If you have minimal knowledge, mechanic time.

Send your message to us

QB Series Peripheral Pumps with Brass Impeller

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords