QB Series Peripheral Pumps with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application of the pump:

1> Clean Water without abrasive particles, non-aggressive liquid.

2> Domestic use.

3> In particular for delivering water in combination with small pressure sets and for irrigation.

4> Installed in enclosed places, or at least protected against inclement weather.

2. Operating conditions.

1> Suction lift up to 8m.

2> Liquid temperature up to +40℃

3> Ambient temperature up to +40℃。

4> Max. working pressure: 6bar.

3. Motor description:

1> 2-pole induction motor: 50Hz.

2> Insulation: Class B.

3> Protection: IP44.

4> With capacitor and thermal overload protection.

4. Material of the pumps:

1> Pump body: Cast Iron.

2> Motor bracket: Aluminum.

3> Impeller: Brass.

4> Shaft with rotor: Stainless steel or CS45#

5> Mechanical seal: Ceramic-Graphite.

6> Copper Winding.

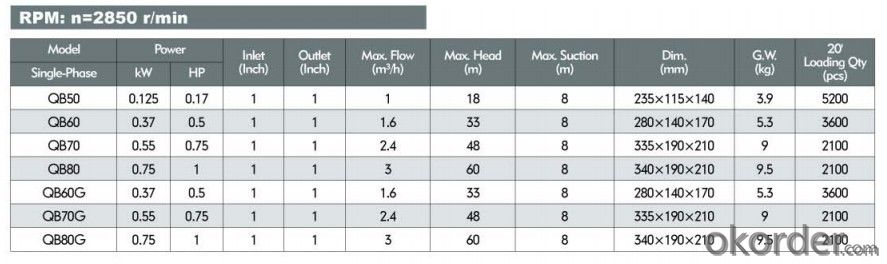

5. Detailed specification for the pumps:

6. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- 1) oil rotary vane vacuum pump is too low, no effect on the oil seal exhaust valve, rotary plug to refuel after large exhaust sound, and oil mist, that the level is too low, the gas can be eliminated.(2) the vacuum caused by the condensable steam pollution of oil should be changed, and new vacuum pump oil should be replaced.

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- If the fish tank is made of metal, the fish tank is grounded or connected to the zero line, and then the fire line is put into the water, then your fish will be electrocuted immediately. Go back to the submersible pump, submersible pump line and the zero line very close, even if the firing line and the zero line at the same time the leakage occurs, fish could not swim between the firing line and the zero line, so the tank submersible pump leakage will cause the following hazards: 1, electric shock. 2, submersible pump short circuit. 3, the submersible pump serious fever, resulting in water temperature tank.

- Q: What are the basic technical parameters of the pump?

- The basic parameters of the pump, the basic parameters of the main performance parameters of pump are the following: first, water pump flow Q flow is the amount of liquid in the pump unit time delivery out (volume or quality). The volume of flow with Q that the unit is: m3/s, m3/h, l/s and so on. The quality of flow unit is expressed in Qm. T/h, kg/s and so on. The relationship between mass flow and volume flow is Qm= P Q density in P - liquid (kg/m3, t/m3), room temperature water P =1000kg/m3.

- Q: What is the difference between centrifugal pump and positive displacement pump?

- The centrifugal pump is usually driven by an impeller, and the head has a functional relationship with the flow rate. Positive displacement pump is gear or piston drive, each stroke output flow is constant, and the head does not matter, the pressure head can be infinite.

- Q: Water pump does not produce water, what are the reasons?

- The reason why centrifugal pump does not produce water:1. pump inlet or sink, water tank water shortage.2. water pump pipe blocked or valve not open.

- Q: Household automatic booster pump, how much pressure to work automatically, the water pressure and how many kilograms?

- With the pressure does not matter, because the pressure is small, it is necessary to boost the pump, the water pressure with the pipe flow and the size of the booster pump related

- Q: How can I buy a pump?

- 2, must meet the characteristics of the media requirementsFor the delivery of flammable, explosive, toxic or valuable medium pump, requiring reliable sealing shaft or the use of non leakage pump, such as magnetic drive pumps (without shaft seal, using isolated magnetic indirect drive).For the transmission of corrosive medium pumps, convection components are required to use corrosion-resistant materials, such as fluorine plastic corrosion resistant pump.For conveying pumps containing solid particles, wear resistance materials shall be adopted in convection parts, and clean liquid shall be used for shaft seal when necessary.

- Q: The working principle of magnetic pump

- Working principle of magnetic pumpN of the magnet (n is even) arranged according to the laws in the magnetic clutch assembly inside and outside the magnetic rotor, the magnet part consisting of magnetic coupling system. When the inside and outside the two poles in different relative displacements, two poles between the angle phi = 0, the lowest energy magnetic system; when rotates to the relative displacement is two poles, pole angle between phi = 2 pi /n, the magnetic system of magnetic energy. Remove the external force, due to the magnetic system of magnetic poles repel each other, magnetic magnet will return to the lowest energy state. So magnets in motion, driven by the magnetic rotor.

- Q: What is a vacuum pump for?

- You are not confused by different names. It is mainly used in folding machines, paper cutting machines and water treatment aeration

Send your message to us

QB Series Peripheral Pumps with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches