Electrical Driven Vertical Fire Fighting Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electrical Driven Vertical Fire Fighting Pump

1.Structure of Electrical Driven Vertical Fire Fighting Pump Description

Electrical Driven Vertical Fire Fighting Pumps are late-model products developed strictly in accordance with the latest-issued GB6245-2006 Performance Requirements and Testing Methods for Fire Pumps responding to the actual and special needs in market. XBD series fixed fire pumps are tested by National Quality Supervision & Test Center for Fire Fighting Equipment.They are conforming to or even higher than the standard in respect of performance index. This kind of pumps are provided with four structural types to meet the different requirements of users, including vertical single-stage, vertical multistage, horizontal single-stage and horizontal multistage.

2.Main Features of Electrical Driven Vertical Fire Fighting Pump

• Compact structure, good appearance, low construction

•Highly efficient, Energy saving

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Comply with requirements of Standard EN 733 (DIN 24255)

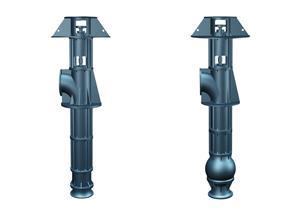

3. Electrical DrivenVertical Fire Fighting Pump Images

4.Electrical Driven Vertical Fire Fighting Pump Specification

Material | Cast iron/Stainless Steel |

Pump diameter | 350-1600mm |

Flow range | 1~200L/s |

Pressure range | 0.2~2.25MPa |

Motor power range | 1.5~200kW |

Inlet/outlet Diameter | DN50~DN200mm |

5.FAQ

①What is the applications?

The Electrical Driven Vertical Fire Fighting Pump is used for water suppply for fire fighting application.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: how do u know when u need to replace ur water pump or how do u know when its not working??? thanks

- The engine will overheat if it's not working at all.

- Q: Weap seal is starting to leak and getting some noise from the water pump. These cars are not as easy as a 1969 Camaro to change the water pump. Can you please give me some guidance? Thx in advance.

- It's easier than you think. Pull front covers off under hood that cover radiator area. One is a plastic guard and under that is the metal support. Pull electric fan out by onbolting it from sides and 2 clips on top and eletrical connector. Now you have room to work. Loosen belts by losening bolt in center of pulley then loosen them by turning adjustment bolt. pull off belts then pull off these pullies with their brackets as one unit off front cover. Take off front covers by taking off 10mm bolts. Crank area has a triangle shaped plate and you can and just loosen bottom 10mm bolt and take off the two above. now slide cover up and you can see water pump. Set cams on their marks for reference, they have a dot on cams and a slot on housings. loosen timing belt tensioner on bottom of engine and evenly pull bolts to get slack on timing belt about one inch should be enough. now you can pull pump off and slide it out being carefull not to let belt slip on cams and lose timing. install the same way, then slowly turn each bolt up on hydrolic tensioner to ease tensioner center pin back to position. make sure timing marks are ok then put everthing back by reverse order. Or you can also pull radiator and bottom crank pulley with a 3 jaw puller and replace belt with new one. This involves pulling out tensioner also. tensioner can be collapsed in vice slowly then use suitable pin to go through cener pin and its case to keep it collapsed, set on new belt and pull pin after tensioner is installed to set belt tension. I hope this helps, Iv'e done this on a few 3.5 litres my self. GOOD LUCK.

- Q: I am trying to increase the pressure of my shower and I am looking to install a water pump. Does anyone know what kind of pump would work well for this? I don't want a big pressure pump, just a small one that will be cheap.

- Before you go to the expense of installing a pump to boost pressure, be sure that you don't have a water VOLUME problem. Buy a pressure gauge (about $20) and connect it to your outside hose bib. If your pressure is about 40 psi, then you don't have a pressure problem. If you live in the USA, the Feds (aren't you glad they're looking out for you?) have mandated that no more than 2.5 gallons per minute can flow out a shower head. That's not much volume. So, I would look for a restriction device in the shower head. If the device is part of the shower head, you can't do anything about it specifically. Compare it to a garden hose and a soda straw with 60 psi water pressure. The soda straw won't provide the volume of water that a garden hose would provide. It would seem that the soda straw has less pressure, but it does not. Normal residential water pressure is on the order of 40-60 psi (I have 85 psi). But if new construction continues in my neighborhood, my pressure will decrease because more demand through a fixed size pipe means lower pressure..

- Q: We are leasing land from a friend to put horses on. We're in the process of building a barn. We don't want to run water out there because its too much trouble for the meter and everything, but someone said to get a water pump and pump the water from the pond and filter it and use it. I have no idea what all we need or what kind of pump to get. Helpp!

- There are many choices and lots of problems. You probably can use a small system with garden hose even depending on how much water you need. There are a lot of variables to define. How much water ie gallons per day? How far do you have to pump it? Is it uphill or downhill? What quality is the pond water? Filtering is a little harder but you should find in line systems or something on the web once you determine the flow rate etc. That may determine the rate you can pump at ie the filter capacity. Do you have electric? If not you need a gas setup pump or generator. What kind of storage tank are you going to pump water into? Sounds like your filter will be the big thing. If you pump 100 gal thats about two bathtubs full. If you pump that in 100 minutes that is 1 gallon per minute. Thats small. So if you can find a filter to do say 1 to 10 gpm and that type pump you can do two bathtubs or more in two hours or so. If you go to 10 gpm thats about the max for a garden hose. Thats more what you would want to spray from the system. Your filter is the key. How clean is the water? Then you need a pump for the flow rate and pressure that can go through the filter. City meter sounds easier now doesnt it?

- Q: gould water pump model Jo5n

- move it up only difference is how far the pump will push water, you will get better pressure from a deep well pump,

- Q: Hello, i have a 1987 volkswagen cabriolet that i purchased earlier this year. So far its been a pain in the butt. Recently i noticed it overheats real quick, but it didnt use to. then i noticed the coolant/antifreeze was being used up like no other! I discovered, after being parked at work, that it was leaking. it leaks basically anything i put in there now!! it leaks from the water pump housing,.,.... at least thats what the internet said it was.. its leaking from the end of the hose that connects to the engine... (the hose that comes from the coolant reservoir.) What do i do? I dont feel any cracks? does this part crack? is it an o-ring or somehting? how can i fix it? what happens if i dont? I am really absolutely NOTHING ABOUT CARS. Please help!!

- Water Pump Housing

- Q: Is there a way to test and see if it is the water pump that causes the car heater to blow hot air one time and then, next time it blows cold air? We flushed the heater core and did other tests, so we do not believe it is the heater core. We left the radiator cap off and ran the car (ford thunderbird..'94) for 20 minutes and watched the antifreeze level come up, but doesn't go down, not circulating. We cannot afford to go to another garage. None of them seem to know what to do anywyas and we keep paying people to fix the heater and it is not fixed. We have put two new thremostats in car, too, figuring that maybe the first one may have been faulty, but should we try that again?

- The radiator actually holds the water/coolant and the pump circulates the mixture throughout the engine. Upon returning to the radiator, the water is cooled from air passing through the fins of the radiator. The pumps job is to circulate the mixture in order for the hot water to cool hence, the engine is then cooled.

- Q: i heard a water pump should not be able to move.is that correct? It is a 1995 RM250. there is no clogging in the pipes coming from the radiators with 2 fingers require force to move them but with the 1 finger it requires no force to move a couple Centimeters.

- The water pump is turned by the primary gear on the crankshaft. When you were turning the water pump - the crankshaft was moving the piston up down in the cylinder. The couple of centimeters of movement is just the play between the gears - that's normal.

- Q: My 1998 Dodge Dakota V6 heater only gets warm, I have replaced the thermostat. I have back flushed the heater core. The heater hose coming from near the thermostat gets hot, but the hose coming from the heater core going to the water pump only gets warm. The large hose coming from the thermostat is hot near the engine, but is only warm near the radiator. Is the water pump bad? If I open the radiator cap there is no signs of circulation. How do I check the water pump?Thanks,Gene

- plugged heater core? the fact that the hose gets hot lets you know that the water pump is circulating coolant.

- Q: I would like to know some details about water pumping (ie. coca cola pumping water out of india) i just wanted to know some sort of prosedure like do they dig a hole and pump or what? I can't find any useful other information when i search it all that it says is that they quot;pumped waterbut nothing more. Thank you =)

- Usually they look for an underwater spring or reservoir, then they drill or dig into it. From there, they either instal a pump or use it as a well. As for how it works, refer to water pressure.

Send your message to us

Electrical Driven Vertical Fire Fighting Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords