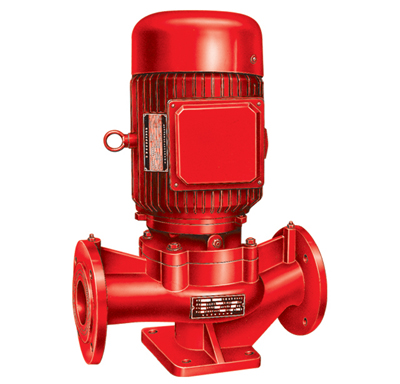

Vertical Stage Fire Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single stage single suction vertical fire pump is newly developed according to market needs.Its performance,technical conditions conform with international standard ISO2858 and requirements for national standard GB6245-2006《Performance requirements and test methods for fire pumps》.It combines with the characteristics of the most advanced hydraulic model and vertical pump.The product is high efficient and energy-saving,reliable performance,easy to install and use.

XBDG series fire pump transports clean water or liquid with physical and chemical property similar to clean water.Using temperature is less than 80℃.

Application Area

It has been widely used in fire fighting and living water supply of industry the residence buildings.

Parameter range

Inlet diameter:25-300mm(1"-12")

Capacity:20-200L/s

Head:0.3-1.28MPa

Rate of rotation:2900r/min、1450r/min

Power:0.75-250kW

Two seal types: stuffing seal or mechanical seal

Structural Characteristics

Pump is vertical structure,motor cover and pump cover are connected to be designed.Beautiful appearance,little occupied area.It can be used outdoor if a protective cover is installed.

Inlet and outlet diameter of pump are the same and they are on the same center line,which can be installed on the pipeline directly just like valves,and the installation is very convenient.

Excellent foot design makes the installation and steadiness of pump convenient.

Pump shaft is lengthened shaft,and this solves the vibration problem caused by coupling drive that is applied by common centrifugal pump shaft and motor shaft.Chromeplate treatment shall be proceeded on surface of pump shaft,which greatly prolongs the service life of pump.

Impeller is directly installed on the motor lengthened shaft.There i no noise when pump is operating,motor shaft applies low noise bearing,which greatly improved the operating environment.What’s more,non-malfunction working time of pump has prolonged 3 times than the common pump.

Mechanical seal is used on the shaft seal,which solves the severe leakage problem caused by packing seal of common centrifugal pump.Static ring and rotating ring of sealing are made of silicon carbide,which prolongs service life of seal.

There is a exhaust hole on the pump cover.Outlet hole and pressure hole are on the flanges downside and two sides of pump casing in order to make pump operate,maintain normally.

Unique structure,so there is no need to dismantle pipe system.Just dismantle pump cover nut,then begin to maintain.It is very convenient.

Series connection,parallel connection and enlarging of pipe diameter can be applied according to requirements,namely,capacity and head.

Max working pressure of pump system≤1.6MPa,namely “pump suction pressure+pump head ≤1.6MPa”.When ordering,system working pressure shall be marked.If pump system working pressure is more than 1.6MPa,it must be specified when ordering so that cast steel material can be applied when manufacturing.

Environmental temperature<40℃,relative humidity<95%.

Volume content of solid particles in the transported medium shall no exceed 0.1% of unit volume,granularity<0.2mm.

Remarks:If medium contains tiny particles,please specify when ordering,so that the wear-resistant mechanical seal can be applied.

- Q: What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) pump connected outside pipes, containers, pipes, joints and other leakage test instrument, large leakage, rotary gas plug exhaust sound big, and the gas and oil mist discharge, should find leakage cancellation.(2) the assembly of rubber of intake pipe is not proper, damage or aging should be adjusted or replaced.(3) plug hole, the vacuum degree can be decreased, put the oil, remove the tank, loosen the nozzle plate, pull out the oil inlet nozzle, dredge oil hole, try not to use cotton wipe parts.(4) the vacuum system has serious pollution, including containers, pipes and so on. It should be cleaned.(5) the spring of the vane is broken and should be adjusted.

- Q: What are the important parameters of the pump?

- Pump parametersFlow rate QFlow is the amount of liquid (volume or mass) that is pumped out in unit timeVolume flow is expressed in Q units: m3/s, m3/h, l/s, etc.

- Q: What is double hydraulic pump?

- Two hydraulic pumps installed on one shaft can be connected to increase output flow, and can also be connected to increase output pressure. See how the demand is. The system can change the mode of application at any time.

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- When the vacuum pressure is called vaporization pressure, cavitation is more than the surplus energy of vaporization pressure at the unit weight of the liquid in the pump suction port of the unit, with mark. The absorption process is to NPSH delta H: pump suction fluid allows the vacuum pump installation height is the unit of rice.

- Q: I would like to ask, constant pressure pump set pressure 20Mpa, the actual load is 15Mpa, then the constant pressure pump outlet pressure? If it is 20Mpa, then where is the loss of 5Mpa? If 15Mpa, the constant pressure pump 20Mpa how to understand? In addition, the constant pressure pump pressure is defined when the flow began to reduce the point, or a sharp drop in flow after the point?

- The pressure loss is borne by the valve. Constant pressure pumps generally do not export direct load, unless you need this load response is very fast, then the maximum displacement of the pump work, so as to ensure the rapid response of the load.

- Q: Bolus dosage of infusion pumpWhat is the purpose of the pill dose control in the special safety standard for infusion pumps? If the risk is not properly controlled, what is the degree of risk? And how can the open infusion pump be used in this regard?

- (three) infusion limited number of pills produced after the dose of obstruction by infusion pump and specification of the matching test, will reach acceptable when the storage pressure of the pressure to determine the alarm blocking. Thus, some have restrictions on the infusion tube blocked after the maximum dose pill may have blocked the trigger before the alarm.

- Q: Harm of air pump and pump

- If the liquid is not full, this situation is generally the suction pipe or pump shell leakage, then easy to cause cavitationHit the pump for centrifugal pumps, centrifugal pump is recommended to start closed, the discharge valve closed, starting is in the state of pump

- Q: Is the flow meter in front of the pump or after the pump?

- After the pump, the reasons are as follows, before the pump, you pump fluid through the pump will produce negative pressure in front of the pump, negative pressure on the flow of the life of the impact, the pump will not, Suzhou first Chi meter

- Q: Why is the flow of the pump too small will occur cavitation phenomenon?

- Throttling regulation is to change the opening of the valve to change the flow of the pump, that is to say, to change the characteristic curve of the pipeline. The commonly used to regulate the flow of exports, because the entrance throttle makes reduce the inlet pressure caused by cavitation danger.

Send your message to us

Vertical Stage Fire Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords