DIN 24255 Horizontal End Suction Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

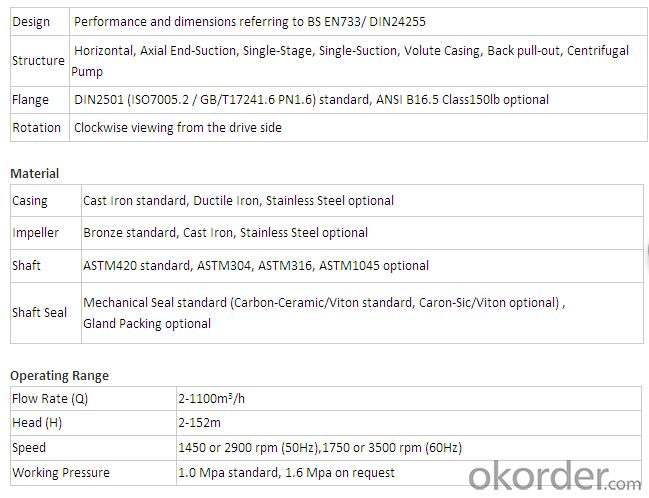

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q: When I turn on my pump for the pool water-fountain it will run for 30 seconds or 4 minutes or anywhere in between then it just shuts off. I push the remote on button on again and it runs for a few seconds. Sometimes it will run for a while longer but mostly short durations. Thanks in advance for your help.

- For it to cycle it fairly is maximum possibly a overheat thermostat change someplace on the motor. A fuse would not reset itself. Are you particular the pump is circulating water. If water isn't flowing and motor is on motor can particularly overheat. have you ever tried priming the pump; the pump can no longer artwork if there is air in the pump or pump intake line (pour water down the pump to do away with air)

- Q: ok so im wondering if there is a water pump out there i can buy that automatically turns on when i turn the tap on. i looking for something thats strong enough to pump enough water to more than one taps at a time i.e kitchen tap, bathroom etc.

- There are plenty of water pumps in the market , and the pump switch is connected to the water flow to operate the pump when the water flow and switch off when there is no flow

- Q: i want to make this for a physics project for school. i found a video on how to make it, but i dont understand the physics behind. i have to make a model and a poster explaining the physics. i dont understand what to put on the poster so could someone help me with which physics principles this project would go with?

- It isn't practical to give a detailed description here. This is a positive displacement pump. The pump chamber is sealed so that as the piston is moved up the volume within the chamber increases. Water is pushed into this chamber by the outside air pressure. If the pump is located too far above the water source then the air pressure is not sufficient and you will produce a vacuum inside but the water still will not flow. When the pump is pushed down the water flows out. Now the one way valves are critical. We don't want the water to flow back the way it came and we don't want the water that we have already pumped to flow back into the pump. So a one way valve on the inlet will permit water to flow into the pump but not out of it. And a one way valve on the outlet will permit water to flow OUT of the pump but not into it. So with each stroke you a) reduce the pressure in the pump. b) water is forced from the inlet, past its one way valve and then into the pump. c) the pump is pushed down increasing the pressure in the pump. d) water flows out of the pump through the other one way valve and on to the output.

- Q: I just had the water pump replaced, now less than a week later it is overheating again and sometimes blowing cold air. What does this sound like it would be?

- Thermostat.

- Q: I would like information to use an automotive water pump to ( or possibly another device ) to pump water approximately 60 feet (20 meters) elevation from creek without electricity. I only need enough water for 25 chickens. So we are not talking about a households supply of water.

- The radiator actual holds the water/coolant and the pump circulates the mixture by skill of the engine. Upon returning to the radiator, the water is cooled from air passing by skill of the fins of the radiator. The pumps pastime is to pass the mixture to confirm that the nice and cozy water to kick back for this reason, the engine is then cooled.

- Q: What is a 1 inch water pump?

- The caliber of the water inlet and outlet pipe is 1 inches of water pump,

- Q: how much would they charge me to change a water pump on my 1999 cadillac deville

- well.... if the fuel was pumping before it ran out of gas, it probably pumps still... the pump wont stop pumping just because it ran out of gas.. but... if you do run out of gas, you WILL get AIR in the lines, and it COULD keep the car from starting because of a bubble somewhere in the lines that won't allow fuel to pass. hard to explain. Diesels have this problem a lot more than EFI cars do, but it can still be an issue. try going out there and turning the key on and off about a dozen times, but not trying to START the car.. every time you turn the key, you should hear a mmmmmmmmmmmmmmmmmmmmmmm sound from the back of the car. that's your FUEL PUMP priming. if you DONT hear the humming sound (which does stop after about 2 seconds) then your fuel pump isn't working. let it prime a few times. when there is too much pressure, a separate line pushes fuel back to the tank.. it SHOULDNT be that big of a problem, but i'm not sure about that exact car.. i have a feeling it's a northstar v8 or something, and those are notorious for sucking donkey nuts.

- Q: Is a 3000 watt generator sufficient to power a 3/4 horsepower water pump?My house has a 3/4 horsepower pump that it uses to pump water from the well to the house. I want to purchase a generator that will be sufficient to power this pump in a power outage. Is 3000 Watts sufficient?

- Danny and GTB give a good answer, I just add some: As a rule of thumb, 1 horsepower (HP or hp) is equal to 750 watts, and a motorized electric equipment at start up will suck electricity power about twice as much as its specification. Is you pump equipped with a three phase or a single phase electric motor? You have to suit it with the generator. As for the generator, if possible you choose a generator with big flywheel, with slower RPM -rotations per minutes- than a generator with high RPM, because a water pump will frequently on and off according to the usage. This could cause the generator to wave down and up accordingly. Or a generator equipped with an electronic governor that will react fast enough to the frequent on and off load of the water pump. Hope the best and God bless you and good luck day by day!!

- Q: water pump on a Suzuki forenzakia optima

- You better shop around on that one but you're looking at a few hundred dollars minimum. The newer the car, the more you're going to pay to get it fixed.

- Q: Hi. This car is 66 chevy but the motor is a 1984 chevy 350 4bolt main stroked to 383. I think its an '84, might be an '85. I need to replace fan clutch and water pump.... the fan clutch is bad but manufacturer of the replacement parts says you must do water pump and fan clutch together. Is the pump a 66 chevy pump or a 350 small block pump? What about the fan clutch? Ok, and please help with motor mounts. do I use mounts specific for 66 model or specific to the motor?

- It's a Gen 1 small block V8. There are only two types of small block water pumps, long shaft and short shaft. Short shaft pumps were used on pre 1968 motors. The long pump measures 7 1/4 from the mounting surface to the outside of the clutch mounting flange, the short pump measures 5 5/8. The mounts should be for a small block in the same body type you are using it in. Back in the 50's there was a different mounting system that bolted to the front of the block, but everything since then is compatible. By the way, if the motor is in a 1966 body with the standard radiator, use the short water pump, iron or aluminum makes no difference except in cost.

Send your message to us

DIN 24255 Horizontal End Suction Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords