CONTAINER HOME,CONTAINER HOUSE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

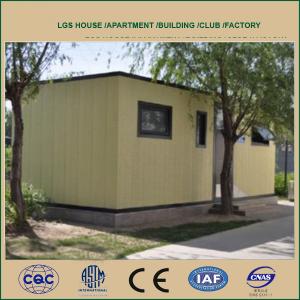

Container House

cost-efficient, expandable in each direction, transportable

Container House

1. GENERAL

The standard container for various purposes is suitable for international container transport. It is of appropriate external dimensions and has connections for lifting and fixing or compounding. The container is designed as a light construction consisting of floor and roof frames and corner profiles. The construction enables compounding of individual containers in longitudinal and transverse directions without limits. It also enables compounding of containers in 2 floors in height (ground floor + first floor), or in 3 floors in height for warehousing of these containers (ground floor + 2 floor).

The wainscots of the container are made of light insulation panels and offer pleasant climate in the interior due to their building and physical properties.

Delivery: Containers can be delivered assembled or individually in kits 648 mm high.4 kits can be bundled in packages 2591 mm high (ISO dimensions)

2. DIMENSIONS and TARE (ISO Standard 1161)

-External length 20/(inner length) 20: 6.055m/(5.851m)

-External width/(inner width): 2.435m/(2.231m)

-External height/inner height: 2.790m/(2.510m)

-Tare: 1950 Kgs

3. STEEL FRAMEWORK

3.1 Material: cold formed steel profiles in a thickness of 3 to 4mm (bottom rails).

3.2 Surface working: electric galvanization min 15 μm, zinc compatible epoxy ground coat in a thickness of 30μm , final zinc compatible vinyl acrylic coat in a thickness of 60-70μm.

3.3 Fittings: 8 comer fittings (dimensions according to ISO standard 1161), rainwater pipe in the roof framework, plate thickness of 10mm excluding top corner fittings of the top kit of each bundle (20mm thickness)

3.4 Forklift openings: openings for fork-lift pockets in the floor framework, dim 88×250mm in a distance of 1200mm

4 .FLOOR

4.1 Composition:

-external wainscot: flat galvanized steel sheet metal in a thickness of 0.5mm.

-insulation filling: non combustible mineral wool in a thickness of 100 mm among steel transverse supports. Mineral wool density: 60 Kg/m3

-steam blockade: PE foil in a thickness of 80μm

- plywood panel in a thickness of 18mm

-glued PVC flooring covering in a thickness of 1.5mm.

4.2 Permitted loading : 2.50 KN/m2

4.3 Coefficient of thermal conductivity: l=0.039 W/mK

4.4 R value (Thermal Resistance) = 2.56 m2K/W

4.5 XPS insulation option: it is possible to choose an alternative insulation filling: extruded polystyrene (XPS) in a thickness of 80 mm among steel transverse supports.

XPS density :35 kgs/cubic meter

Coefficient of thermal conductivity: l=0.029 W/mK

R value (Thermal Resistance) = 2.76 m2K/W

5. CEILING:

5.1 Composition:

-external wainscot: flat galvanized and painted steel sheet metal in a thickness of 0.5mm.

-insulation filling: non combustible mineral wool in a thickness of 100mm among plywood purlins. Mineral wool density: 60 Kg/m3

-steam blockade: PE foil in a thickness of 80μm

-inner wainscot: chip wood panel in a thickness of 9 mm with a foil in white color; joining of chip wood panels with PVC profiles

5.2 Meteor water outlet: 4 each of PVC rainwater pipes, diameter 50mm in corner pillars

5.3 Permitted loading: 1.50 KN/m²

5.4 Coefficient of thermal conductivity: l=0.039 W/mK

5.5 R value (Thermal Resistance) = 2.56 m2K/W

6. FACADE WALLS

6.1 Side panels width: 1145mm; total panel thickness: 70mm.

Five panels fit into the long side and two panels fit into the short

side of container and they are fully interchangeable

6.2 Composition:

-External wainscot: galvanized and painted steel sheet metal in a thickness of 0.5mm.

-Insulation filling: non combustible mineral wool in a thickness of 50mm in the wood framework. Mineral wool density: 60 Kg/m3

-Inner wainscot: chip wood panel in a thickness of 9 mm with a foil in wood pattern (bright oak or white).

Joining of panels with PVC profiles. Final elements in the interior are made of chip wood panel in a thickness 8mm with a foil in wood pattern.

6.3 Permitted loading: 1.00 KN/m²

6.4 Coefficient of thermal conductivity: l=0.039 W/mK

6.5 R value (Thermal Resistance) = 1.28 m2K/W

6.6 100 mm insulation option: the framework can be modified so that mineral wool insulation reaches a thickness of 100mm. In this case R value (Thermal Resistance) goes up to: 2.56 m2K/W.

Note that 100 mm thick wall panels are not fully interchangeable like standard 50 mm ones

7. DOORS

Standard external door. Single fold, 40mm thick, made of:

· a frame in prepainted aluminum

· hot galvanized and prepainted steel sheets (inside and outside)

· insulated with PL (polystyrene)

Opening dimensions of 808×2030mm, furnished with a handle lock with 3 keys.

Net opening dimensions: 754 x 1985 mm.

Also 845 x 2000 mm net opening is available.

8. WINDOWS

8.1 Windows

Option 1: made of PVC, white color, with dimensions 800×1100mm, glazed with double layer glass in a thickness of 4/15/4mm, with sliding mechanism (one side fixed and one sliding)

Option 2: made of PVC, white color, with dimensions 800×1100mm, glazed with double layer glass in a thickness of 4/15/4mm, with tilt and swing mechanism

Option 3: made of PVC, white color, with dimensions 800×1200mm, glazed with double layer glass in a thickness of 4/15/4mm, with tilt and swing mechanism

8.2 Rolling shutters

Option 1: external PVC rolling shutters in PVC guides.

Option 2: external Aluminum rolling shutters without insulation in Aluminum guides.

Option 3: external Aluminum rolling shutters with insulation in Aluminum guides.

9. ELECTRICAL INSTALLATIONS

9.1 Standard: according to VDE 100 and CE regulations

9.2 Voltage: 220 V, 60 Hz single phase

9.3 Network connections: CEE-connection plus/socket, 3-pole 32 A, 220V, mounted on the top frame in upper corners of a shorter side wall

9.4 Inner distribution system: BVVB cables of suitable dimensions (6, 2.5, 1.5 mm) ,CE marked , flush-mounted.

All cables (located on the ceiling and inside wall panels) run into CE certified plastic conduits. Roof cables and panel cables are connected with CE compliant jacks. All jack connections are protected inside CE marked and IP44 rated distribution boxes.

9.5 Protection: protective current switch (40/2E-0,03A), automatic fuses (B-characteristics) of suitable power (10A, 16A)

9.6 Earthing: galvanized connector with a steel plate of

dimensions 30x80mm welded on the bottom frame

- Q: Can container houses be designed to have a loft or mezzanine level?

- Yes, container houses can be designed to have a loft or mezzanine level. The modular construction of container houses allows for flexible floor plans and multiple levels can easily be incorporated into the design. A loft or mezzanine level can provide additional living space, create separate areas for different functions, or serve as a sleeping area. By utilizing the vertical space, container houses can maximize the available square footage and offer a unique and efficient living experience. Additionally, the industrial aesthetic of container houses can be enhanced by the inclusion of a loft or mezzanine level, creating a visually appealing interior design. Overall, container houses are highly adaptable and can be customized to accommodate various needs and preferences, including the addition of loft or mezzanine levels.

- Q: Can container houses be designed with a built-in security system?

- Certainly, container houses have the potential for incorporating a built-in security system. Many manufacturers and designers of container houses recognize the significance of security measures and provide a range of options to enhance the safety and security of these dwellings. One prevalent strategy involves integrating surveillance cameras into the security system. These cameras can be strategically positioned around the house to monitor the surroundings and discourage potential intruders. Moreover, motion sensors can be installed to detect any movement on the property and activate an alarm when necessary. Another vital aspect of security pertains to the entry points of the container house. Manufacturers can equip the doors and windows with resilient locks and reinforced materials to bolster their security. Some designs even feature smart locks that can be remotely controlled through a smartphone, enabling homeowners to lock and unlock their doors from any location. Furthermore, container houses can be seamlessly integrated with security systems that encompass alarm systems, smoke detectors, and even home automation capabilities. These systems can be connected to a central control panel, allowing homeowners to effortlessly monitor and manage all facets of their security system. It is crucial to recognize that while container houses can be designed with a built-in security system, the level of security ultimately relies on the specific features and technologies implemented. Homeowners should thoughtfully consider their security requirements and seek advice from professionals to ensure that the chosen security system fulfills their needs.

- Q: Can container houses be designed to have an open-concept layout?

- Yes, container houses can definitely be designed to have an open-concept layout. In fact, the modular nature of container homes makes them very adaptable and flexible in terms of design. By strategically placing walls and partitions, container houses can be easily customized to create an open and spacious living area. The walls can be removed or modified to create larger open spaces, allowing for an open-concept layout. Additionally, large windows and skylights can be incorporated into the design to bring in natural light and create a sense of openness. With proper planning and design, container houses can offer all the benefits of an open-concept layout while still maintaining the structural integrity and functionality of the home.

- Q: Can container houses be transported overseas?

- Yes, container houses can be transported overseas. The design and structure of container houses make them suitable for international shipping. They can be easily loaded onto cargo ships and transported to different countries.

- Q: Can container houses be designed with earthquake-resistant foundation systems?

- Yes, container houses can be designed with earthquake-resistant foundation systems. In fact, container houses have been found to be quite resilient in earthquakes due to their structural integrity and ability to withstand lateral forces. To enhance their earthquake resistance, container houses can be built on a strong and flexible foundation system. This can include using deep concrete footings or piers that are designed to absorb and distribute the seismic energy generated during an earthquake. These footings can be strategically placed at key points along the container house structure to provide stability and prevent any potential damage. Additionally, engineers can incorporate innovative design techniques to improve the earthquake resistance of container houses. This can involve using reinforced steel frames within the container structure, as well as implementing bracing systems to provide additional strength and stability. Furthermore, container houses can also be designed with specific seismic codes and regulations in mind. These codes ensure that the container house meets specific standards for earthquake resistance, taking into account factors such as the location, soil conditions, and expected seismic activity of the area. Overall, container houses can indeed be designed with earthquake-resistant foundation systems, making them a viable and safe option for areas prone to seismic activity.

- Q: Can container houses be designed with a multi-unit complex?

- Yes, container houses can be designed with a multi-unit complex. Container houses are versatile and can be easily stacked or arranged in different configurations to create a multi-unit complex. This allows for the construction of apartment buildings, dormitories, or even small housing communities made entirely of container houses. Container houses are built using shipping containers, which are typically 20 or 40 feet long. These containers can be stacked vertically or arranged side by side to create multiple levels or adjacent units. The containers can be modified and connected to form larger living spaces, common areas, or shared facilities. Moreover, container houses can be customized to meet the specific needs and preferences of the residents. They can be designed with different layouts, sizes, and amenities. For example, a multi-unit complex can have units of varying sizes, from studio apartments to larger family-sized containers. The containers can also be interconnected to create shared spaces such as kitchens, bathrooms, laundry facilities, or community areas. Container houses offer several advantages for multi-unit complexes. They are cost-effective compared to traditional construction methods, as the containers are readily available and can be repurposed for housing. They are also eco-friendly, as they reduce waste by utilizing existing containers and promote recycling. Additionally, container houses can be designed to be energy-efficient, incorporating sustainable features such as insulation, solar panels, or rainwater harvesting systems. In conclusion, container houses can indeed be designed with a multi-unit complex. Their flexibility, affordability, and sustainability make them an attractive option for creating unique and innovative housing solutions for various needs and populations.

- Q: Can container houses be designed to have a small carbon footprint?

- Yes, container houses can be designed to have a small carbon footprint. One of the main advantages of using shipping containers for housing is that they are repurposed and recycled materials, which reduces the need for new construction materials. This significantly reduces the carbon emissions associated with the production and transportation of building materials. Additionally, container houses can be designed to incorporate energy-efficient features. For example, proper insulation, low-energy lighting, and energy-efficient appliances can be installed to reduce energy consumption. Incorporating renewable energy sources such as solar panels and wind turbines can further minimize the carbon footprint by generating clean, sustainable energy. Furthermore, container houses can be designed to be self-sufficient in terms of water usage. Rainwater harvesting systems, greywater recycling, and efficient plumbing fixtures can help reduce water consumption and minimize the carbon emissions associated with water treatment and distribution. The design of container houses can also prioritize natural ventilation and daylighting, reducing the need for artificial heating, cooling, and lighting. Additionally, the use of sustainable and eco-friendly materials for insulation, flooring, and finishes can further minimize the carbon footprint. It is important to note that the overall carbon footprint of a container house also depends on factors such as the location, transportation of the containers, and the energy sources used in the construction process. However, with careful design and consideration of these factors, container houses can indeed be designed to have a small carbon footprint, making them a sustainable and eco-friendly housing option.

- Q: Are container houses soundproof?

- Container houses can be made soundproof to a certain extent, but it ultimately depends on the construction methods and materials used. Shipping containers are made of steel, which is not known for its sound-blocking properties. However, with proper insulation and soundproofing techniques, container houses can significantly reduce noise transmission. To achieve soundproofing in a container house, various methods can be employed. Insulation materials such as spray foam, fiberglass, or rock wool can be used to fill the wall cavities to minimize sound transmission. Additionally, double-glazed windows with acoustic glass can be installed to reduce noise from the outside. Furthermore, using resilient channels or acoustic panels on the interior walls can help dampen sound vibrations. Installing acoustic ceiling tiles or soundproofing the floors with cork or rubber underlayment can also contribute to sound reduction. It is important to note that while these measures can greatly improve soundproofing, container houses may still have some level of sound leakage due to the inherent properties of the steel structure. Therefore, it is advisable to consult with a professional architect or soundproofing specialist to ensure the best possible soundproofing solutions for a container house.

- Q: Can container houses be designed with multiple levels?

- Yes, container houses can definitely be designed with multiple levels. The modular nature of shipping containers allows for easy stacking and joining, making it possible to create multi-story structures. In fact, many architects and designers have successfully incorporated multiple levels in container house designs, showcasing the versatility and flexibility of this building method. When designing container houses with multiple levels, certain considerations need to be taken into account. The structural integrity of the containers must be maintained, and additional support may be required to ensure the stability of the upper levels. Proper insulation and ventilation systems should also be incorporated to maintain a comfortable living environment throughout the entire structure. Moreover, it is essential to carefully plan the layout and design of each level to optimize space and functionality. Creating an efficient flow between the different floors, incorporating staircases or even elevators, and considering the placement of windows and openings are crucial aspects of designing multi-level container houses. Overall, container houses can be successfully designed with multiple levels, offering a unique and innovative solution for those seeking compact yet spacious living spaces.

- Q: Can container houses be designed to have a high-end, luxurious interior?

- Absolutely, container houses have the potential to boast a high-end and extravagant interior. By meticulously planning, employing creativity, and utilizing the appropriate resources, container houses can be converted into chic and sophisticated living spaces that rival conventional homes. The key to achieving a luxurious interior in a container house lies in the design and the choice of materials. Collaborating with architects and interior designers, it is possible to create a layout that optimizes space and functionality while incorporating top-of-the-line features. This can entail incorporating open-concept living areas, high ceilings, and large windows to create an illusion of spaciousness and allow an abundance of natural light to permeate the space. To elevate the interior design of a container house, opulent finishes and materials can be employed. Employing high-quality hardwood floors, marble or granite countertops, and customized cabinetry can add an air of elegance to the space. Moreover, luxurious fixtures and fittings, such as designer lighting, premium appliances, and high-end bathroom fixtures, can further enhance the overall ambiance. In terms of aesthetics, container houses provide an unparalleled opportunity for creative expression. The exterior can be clad in various materials such as wood, stone, or metal to create a visually captivating and high-end appearance. The interior can be personalized with lavish furnishings, captivating artwork, and exquisite decor to reflect the homeowner's unique style and preferences. It is important to note that while container houses can be designed to have a luxurious interior, it may necessitate a larger budget and more extensive customization compared to traditional homes. Nevertheless, the inherent sustainability and cost-effectiveness of container houses can offset some of these expenses, rendering it a viable option for those in pursuit of a lavish and eco-friendly living space. Ultimately, with the right design and meticulous attention to detail, container houses can be transformed into breathtaking, high-end residences that seamlessly merge style and functionality.

Send your message to us

CONTAINER HOME,CONTAINER HOUSE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords