China Made Stain Steel Horizontal Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

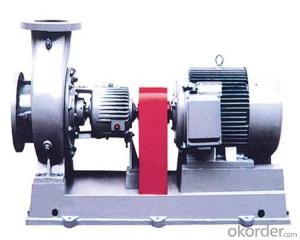

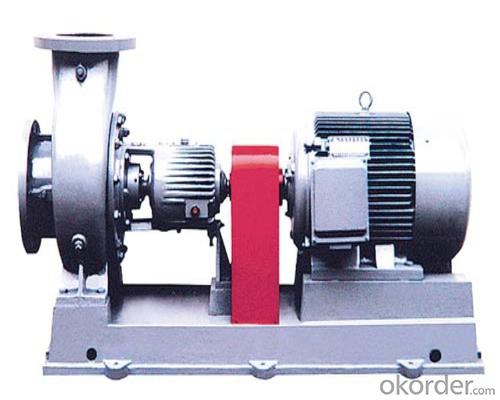

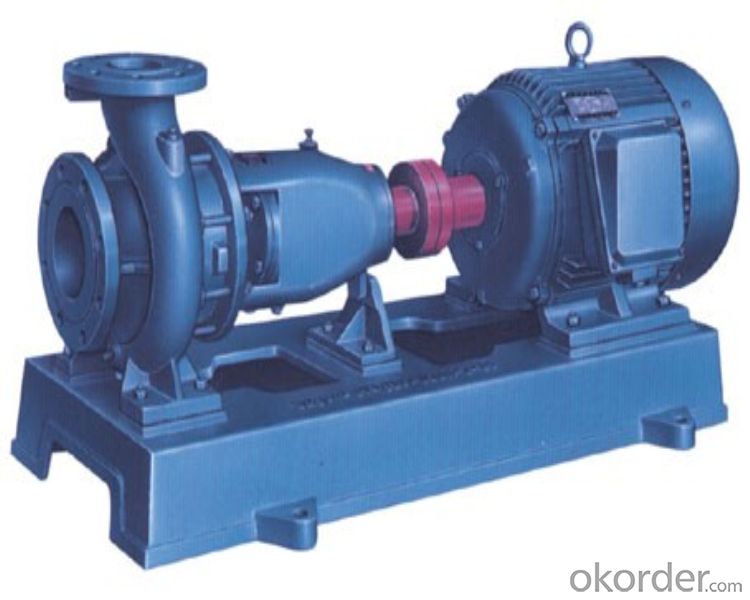

China Made Stain Steel Horizontal Centrifugal Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product parameters of China Made Stain Steel Horizontal Centrifugal Pump

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of China Made Stain Steel Horizontal Centrifugal Pump

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

China Made Stain Steel Horizontal Centrifugal PumpFeatures

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

China Made Stain Steel Horizontal Centrifugal Pump Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: does anyone know how to remove the water pump on an 84 corvette its killing me

- Step 1. Drain the anitifreeze, the fluids in the radiator, you will find a drain plug on the bottom of the radiator. Dont trash this fluid as its harmful to the environment or reuse the fluid. 2. Disconnect the radiator hoses to the radiator and to the water pump. 3. Remove the radiator and fan shroud and transmission lines, it unbolts from the top. 4. Remove the bolts from the fan, remove the fan. 5. Loosen the altenator, A/C and power steeering pump enough to remove the belts. 6.Remove the 4 bolts holding the water pump to the engine, remove the water pump. 7. Let the water dry and clean where the water pump was as you will need a clean dry surface to apply the gaskets to. 8. Put the 4 bolts in the new water pump, put the gaskets on the toward engine side on the four bolts and install the new water pump. I dont know what the torque specs are, just dont over tighten and enough to break off a bolt. 9. Put the belts back on and tighten, reinstall the fan, the radiator and fan shroud and reinstall the hoses. Reinstall the transmission lines. Fill the radiator with anitifreez water mixture. 10. Start up the engine and allow the engine to warm up, keep the radiator cap off to detect the fill level. Fill when warm to about 1/2 inch to the top is a good level/Reinstall the cap. Finish

- Q: Assuming that my water pump standard flow is 20m3/h, tolerance value requirements is + 8%, then is not traffic 22m3/h is not qualified?

- Tolerance coefficient is due in the manufacturing process, will, so each pump products are possible shapes and sizes do not conform to the pattern of the situation, and ensure the test results in the value (operating point) when compared, should be allowed to have a certain tolerance. It should be noted that these tolerances are only relevant to the actual pump and do not involve test conditions and measurement uncertainties.If the pump at a certain working point (the same lift) standard (Design) flow of 20m3/h, the actual flow of 22m3/h, indicating that the pump in the design process has unreasonable place, resulting in waste of power. Deviations from the manufacturing process usually have no positive deviation.

- Q: I think my water pump has crapped out on my 1997 Jeep Cherokee. I have been leaking coolant for a few days now and there is a puddle under my Jeep after I turn it off and my reserve tank keeps emptying out on me. I replaced the lower radiator hose and still the same problem. It is not over heating so I am wondering if it IS a water pump problem? If it is, could I do the work myself?

- If okorder /

- Q: i learned from wikipedia that the water pumps back to reactor where it is heated again and the cycle begins again. but then i saw this diagram

- I can see why you're a little confused. There are actually 3 separate loops in most reactor designs and you can see this in the diagram. The primary heat transport loop contains the water that touches and cools the fuel and this is the water that is pumped back to the reactor where it is heated again.... It is shown in the diagram in pink. The water from the primary heat transport loop passes into a steam generator which is full of water but the water in these two systems is kept separate to ensure all radioactivity stays in the primary heat transport loop and in the containment building. Basically the pipes from the primary heat transport system pass through a large tank of water and heat the water in the tank causing it to boil. The steam is then passed out of the generator, out of containment, and into the turbine. Next it goes into a heat exchanger which is similar to the steam generator except it is used to cool the water. The cooled water then passes back into containment and into the steam generator to be boiled again. Finally, the third heat transport loop moves cold water from either a lake, ocean, or cooling tower, into the turbine building where it cools the water in the secondary heat transport loop. This water is kept completely separate from the water in the secondary heat transport loop to ensure that if the secondary loop water somehow becomes contaminated, it doesn't pass into the third loop and get into the lake, ocean, or atmosphere. I hope that clears things up :)

- Q: does anyone know the proper way to take the lower gearcase off and install a new water pump kit. it is a 1986.

- This is a simple repair but I'd recommend that you get a service manual, ether a factory manual or one of the generic Seloc manuals. The key things to do are mark the trim tab so you can put it back in the same position after repairs. Drain the oil. Removing the bolt that is in the hole at the back end of the upper housing, as well as all the obvious Nuts. both above and under the cavitation plate. Put the drive in forward gear, which takes the tension off the shift shaft. Once all the nuts and bolt are loose. Jiggle the drive and it will separate from the upper housing. You now have access to the water pump housing. Remove the housing and pull it up and off the d. Shaft. Inspect fully and account for missing impeller blades. When you re assemble Lube the impeller and put the drive key in place and put the impeller in place. Slide the housing down to the impeller. You can use ether th drive shaft or the propeller to turn the drive shaft in a clockwise direction as you apply pressure on the housing, It should slide down over the impeller. Reassemble in reverse order. Slide the drive shaft up into the upper housing turning the D. shaft using the prop to turn the shaft. Watch the water tube slip into the guide tube. Once it's in place put a couple nuts on then check the gear shift to make sure it goes F-N-R. Bolt up and fill with oil. Good Luck!

- Q: I'm not familiar w/ this model but need to swap out the water pump. I have no pictures or publications. Anything in particular to watch out for? Is this a pushrod engine w/ a water pump mounted in the front center of the engine and driven by a serpentine belt? Thanks in advance.

- It's very easy to change. It's driven by a serpantine belt but it's off center Right up front closer to the radiator and on top. Break the 13mm pulley bolt's loose, remove the belt, remove loosened pulley bolts and pulley. Then there's like 6, 8mm bolts to remove the pump and that's it. You might have to remove the overflow tank to make it easier to get to. The pump is round and looks like it will go on any 'ol way but it doesn't. It only goes on one way.

- Q: I need instructions

- it really depends on your make and model. different makes and models have different locations for them and what not. the best thing to do is buy a repair manual for your specific vehicle.

- Q: Hi -- could someone please give me information on how much I should expect to pay for a water pump and to cleanse my coolant system (or something like that) or if it's something I really need to do. Or if I can get the water pump without the coolant system...My car is running fine, just started making kind of a rough running sound a few weeks ago when it's idling. ANY advice is greatly appreciated!

- it sounds like to me you dont know what you need. Is your car running hot if not then you dont need a water pump. But if it is then you should do the timing belt at the same time since you need to take the water pump off to do that anyway. timing belts a good for about 100000 mile.

- Q: I have septic tanks. My toilet flushing water is filthy and the water pump runs for a long time and sounds strange. I have turned the pump off for now but know this is not an answer but i was worried it would burn out or something. Do i need a part for the pressure pump? Please help any plumbers out there.

- I'm not sure why you only mention the water in your toilet. Alot of residential wells are just holes in the ground with 10 or 20 feet of casing. That is the large pipe in the ground that keeps the surface dirt from caving in. If the pump pipe- the one that the water comes out of the well in- has a hole in it down below the casing, then when the pump runs water sprays out onto the dirt in the well and is sucked up by the pump. Sometimes the dirt hole will collapse filling the well to a level close to the pump or even above. Dirt in well water should be checked out by a pump company soon. Your pump will wearout faster and if there is a chance of cleaning out the dirt it should be done right away.

- Q: I'm curious to know, where does the water go after it is sent to a pumping station??

- Potable (drinkable) water pumps placed just outside the treatment plant boost pressure in the water mains, where it eventually gets to homes, businesses and hydrants via the pipe network. Most sewers flow by gravity (downhill) to a waste water treatment plant (or septic field). But if an area is too low to be serviced by a gravity sewer, an ejector pump is set at the bottom of a collection well which pumps the wastewater to a higher elevation in a pressure pipe called a force main. A good pump station will kick on about 4 or 5 times an hour and run for several minutes. Eventually it outlets to a manhole in a gravity system and ultimately the treatment plant.

Send your message to us

China Made Stain Steel Horizontal Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords