Stainless Steel Hydro Flask

Stainless Steel Hydro Flask Related Searches

Stainless Steel Flask Flask Stainless Steel Stainless Steel Flasks Stainless Steel Vacuum Flask Stainless Steel Hydrojug Stainless Steel Fountain Stainless Steel Beverage Tub Stainless Steel Humidifier Stainless Steel Glass Stainless Steel Storage Tank Stainless Steel Pressure Vessel Stainless Steel Tub Stainless Steel Hot Tub Stainless Steel Straw Stainless Steel Vessel Hydrojug Stainless Steel Stainless Steel Vase Stainless Steel Canister Stainless Steel Tank Stainless Steel Canisters Stainless Steel Food Dehydrator Stainless Steel Dehydrator Stainless Steel Thermos Stainless Steel Drain Stainless Steel Wine Glass Stainless Steel Dry Rack Stainless Steel Heater Stainless Steel Pet Fountain Stainless Steel Ladle Stainless Steel ThermoStainless Steel Hydro Flask Supplier & Manufacturer from China

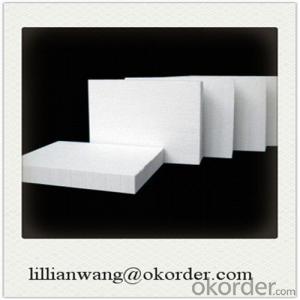

Stainless Steel Hydro Flask is a line of high-quality, insulated beverage containers designed to keep your drinks hot or cold for extended periods. These flasks are crafted from food-grade stainless steel, ensuring that your beverages retain their optimal temperature without any metallic taste. They are equipped with a double-wall vacuum insulation technology, which not only maintains the temperature of your drinks but also prevents condensation on the outside of the flask.The Stainless Steel Hydro Flask is widely used in various scenarios, such as outdoor activities, sports, camping, and everyday use. It is an ideal choice for those who are on the go and need to keep their beverages at the perfect temperature. Whether you're hitting the trails, heading to the gym, or just commuting to work, the Hydro Flask has you covered. Its sleek design and durable construction make it a popular choice among individuals who prioritize both functionality and style.

Okorder.com is a leading wholesale supplier of Stainless Steel Hydro Flask products, boasting a vast inventory to cater to the needs of various customers. With a commitment to providing top-notch products at competitive prices, Okorder.com ensures that you receive the best value for your money. Their extensive range of Hydro Flasks allows customers to choose from different sizes, colors, and designs, making it easy to find the perfect Stainless Steel Hydro Flask to suit their preferences and requirements.

Hot Products