Stain Steel China Made Food Grade Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stain Steel China Made Food Grade Centrifugal Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Stain Steel China Made Food Grade Centrifugal Pump

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of Stain Steel China Made Food Grade Centrifugal Pump

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

Stain Steel China Made Food Grade Centrifugal Pump Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Stain Steel China Made Food Grade Centrifugal Pump Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

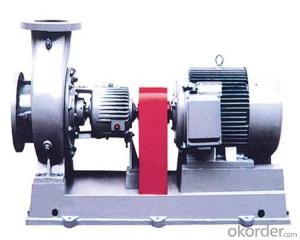

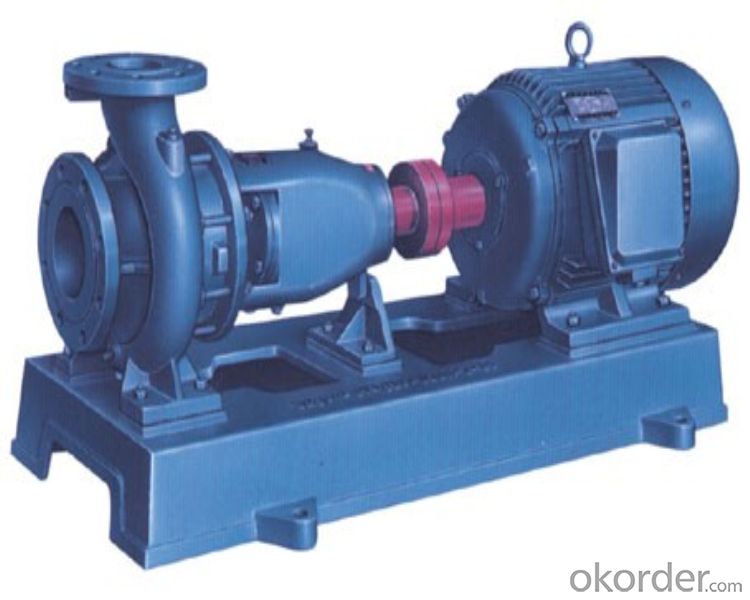

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: A Honda timing belt is suppose to be replaced every 90,000 miles but is it necessary to replace the water pump at the same time? How long will a water pump last? I never had a water pump fail on any Honda I have owned. Of course that is probably because I always had it replaced with the timing belt?

- your there,cheap insurance,is it neccessary,no but that would be insane.

- Q: How do the water pump work please till me water pump mechanism?

- the international is produced from persons, and we've a lifetime to stay. this is our getting at the same time, our sharing and our helping that are the main important factors of life. So, clearly this must be finished between people, and prefer the brook, people come and persons bypass, yet we bypass on living. this is that this interplay it particularly is the objective of life, and finally as quickly as we are nearing our end there are in straight forward terms some left, some who count on us.

- Q: What motor with Grundfos pumps

- General Motors Malaysia gelanfu! Can also be optional!

- Q: I'm going to be purchasing a laboratory distillation kit here pretty soon, the kit includes everything I need for the setup but the condenser requires a water pump to circulate cold water around the coils. What kind of pump would you recommend for this purpose?

- A small centrifugal pump that has the flowrate designated by the condenser manufacturer. I assume it has a heat exchanger of some type to reject the heat to the air and that would need a designate flow. Anyway, look in any lab supply catalog or web site and they will have many small pumps. You do not need to carefully control the flowrate, so stay away from metering or peristaltic pumps. The pumps may even be made of plastic, that is fine for this application. In my lab, we would just run the water from the tap through the glass condenser and let it drain out to waste. It is wasteful of water, but it sure was much cheaper than buying a pump and heat exchanger.

- Q: How much should it cost to have the water pump replaced in a 1994 Dodge Ram truck?

- A new one is about $64 .. You didn't say what engine, so I guessed 1994 Dodge Truck RAM 1500 1/2 ton 2WD 5.2L MFI ? It should take about 2 hours to do this. If you can't do this yourself, I would expect to pay about $80 per hour labor -

- Q: can you replace a water pump gasket without replacing the whole water pump?

- Yes. Just make sure that the pump it-self is not leaking out of a small hole (aka weep hole) or the shaft that drives the pump. and romove the old gasket completly. clean very well. both pump and motor.

- Q: Motor has over 200k miles. Water pump took a dump. Gear is very wobbly! primary timing chain tensioner off the right bank hasn't any tension on chain at all! Crank turns but doesn't turn the chain. So motor is way out of time for sure now.Found small piece of aluminum and 2 -1/2pieces of appears to be a spring pin. Am I correct to assume these pieces are from the water pump? A new chain and water pump I can see doing on this old motor! But? Any suggestions on what to do next before I waste my money? What kind of compression reading can I get with all the plugs out and manually turning the crank? Short answers of scrap it not welcomed! I'll determine that after I'm satisfied it's truly bad! Thanks!

- I also own a 2001 Intrepid and recently had a water pump go bad which also broke my timing chain. The pieces of aluminum you found are probably valves or valve springs from the head. Mine broke every vavle and spring on one head when my engine jumped time and a few more on the other head that is probably what your seeing. Also you don't want to check for compression by turning the crank manually. It is an expensive job to fix but the cars are great but I wouldn't spend too much on them because they only go for about $3000-3700 in great condition nowadays. Good Luck

- Q: Okay so we have a water pump outside instead of city water. A few days ago we noticed that it would turn off like always once the tank was full but then just would never turn back on. It was odd to us since it would always turn on and off at appropriate times. Now its on maybe 10 seconds and it shuts off. I took off one of the clear hoses it has and notices a green ooze inside it. I cleaned out the ooze and tapped some of the pipes in hopes of some more of it coming out. Since we have had a leak there is green stuff which i am guessing is lime, on the side of the tank. I'm also guessing this must bee the green ooze. What should I do? Now there is no water whatsoever being pumped and the time it does turn on very little water passes through. To me it sounds like something is blocking the pipes but if I pay hundreds for someone to come replace the pipes and check out the motor I dont want to end up with this problem again. If anyone has any information as to helping me I would so greatly appreciate it.

- do you have shallow or deep well its the middle of summer the well could be dry you might have lost your prime on your pump there will be a bolt for priming take bolt out pour water in to hole untill full restart pump if pump doesnt fill up you might a stuck foot valve.

- Q: I'm looking to buy a used 2001 Protege. The car is nearing 75000mi, but the owner has not changed the timing belt or the water pump. I found out that it is recommended to change the timing belt at 60000mi, but couldn't find anything on the water pump. Realistically, when would I need to replace these, and any idea how much it would cost?Thanks!

- That could have either the 1.6 liter or 2.0 liter engine. My information shows that if you have the 1.6 liter, at least you don't have to worry about bending valves against pistons if the belt breaks -- you'll just be stuck out on the road until you can get it towed and fixed. Not so with the 2.0 which is an interference engine. So if you DO have the 2.0, pay attention -- you don't want an expensive breakdown! You're on borrowed time at 75K. For both engines, Mazda recommends that you replace the timing belt every 60K miles. Gates (a major replacement supplier) seems to think these belts will go 105K. Since it's a factory belt, stick with 60K. As for the water pump, it's often one of those while you're already in there sort of things when you're doing a timing belt. 60K makes it a tougher call, especially with the better quality of water pump bearings and seals. If your interval were 80K ~ 100K as is true on some cars, I'd say go for it without blinking. As cheap as it'll be (it's really just the price of the pump), and it was my set of wheels, I'd do it anyway, even at 60K, if it needed to be pulled to do the belt.

- Q: I would like to know that a water pump or water motor which is of 1 hp what is the height from which it can pull water ? And also if there is a bubbling sound of air and no water is being supplied what does it mean ?

- we've a Jetta and the water pump went at 30,000 miles. Its meant to very final plenty longer till the timing belt needs to get replaced. the reason they use plastic for the impeller is so if it fails it does not harm the timing belt. whilst the pump fails you may notcontinual the motorcar for any distance, the engine overheats, the warning lighting fixtures furnishings come on and thats it. in case you persevered tocontinual you might have the skill to desire to probably grab the engine or a minimum of blow the precise gasket and warp the precise, those engines are all aluminum and might't stand to be overheated.

Send your message to us

Stain Steel China Made Food Grade Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords