Centrifugal Slurry Pump for Mining and Water

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application and Feature

♣Type ZJR, ZJM, ZJH Pump are cantilevered, horizontal, centrifugal slurry pump.

♣They are designed for the handing high density slurries in the metallurgical, mining , coal, power, building material and other industrial department etc.

♣The pump of this type also maybe installed in multistage series.

♣The frame plates liner and impeller for type ZJR , ZJ(M) pumps have replaceable wear-resistant metal liners or rubber liners, The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only.

♣The shaft seals for type ZJ(R),ZJM, and ZJH Pump may be adoptable of gland seal or expeller seal .

♣The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications

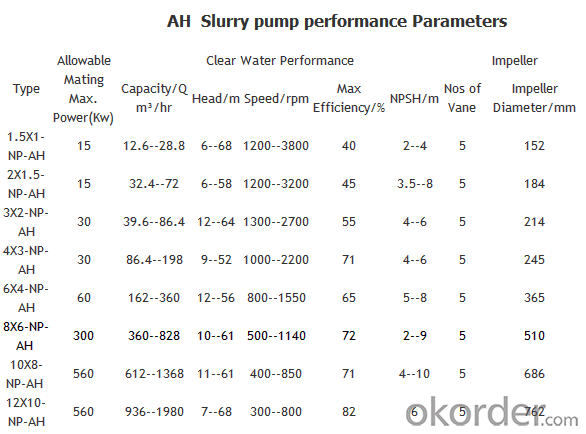

2. Performance Parameters

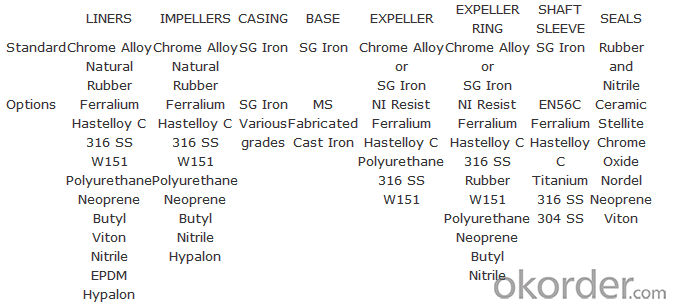

3. Material

4. Assembly Shop & Package

- Q: What I am trying to explain is that I took my vehicle to be serviced for a water pump. They installed it, but when I got my vehicle back, it started making this clicking noise. I took it back to be diagnosed and they came back to me saying that I need a new engine? (Before I took in my vehicle there was no clicking sound or problems, just the water pump.)Could this be the dealer trying to pull something for their mistake or what?

- It is hard to answer given the information given. What kind of car ? If your car has a waterpump that is turned by the timing belt, yes the shop could have messed up on the cam timing as they re-assembled after installing the pump. What is causing the clicking sound ? It could be a bent belt or any of a hundred things. Where do you hear the sound coming from ?

- Q: I have a 2000 Chevy Malibu with 123xxx miles on it. I notice coolant being leaked on the floor heavily and my car gets hot driving. It leaks when the car is on and stops when it is off. Could it be a water pump? What r the signs of a bad water pump?

- When you can't see it on the engine. It is usually at the back of the timing quilt. Many engines are now hooked up that way. The timing belt also runs your water pump. And if you happen to must substitute the water pump. You are going to also replace the timing belt. Which is an efficient thought any method .Considering a 2001 may have many miles ,and nearly able for the belt to break. Leaving you stranded.

- Q: are there any pumps that can save energy more? Environmental protection is necessary and the price is not high.

- Water pump. ( Pond ) Sump pump. ( Flood prevention ) Auto water pump. ( Radiator ) What is the specific purpose of the pump.

- Q: I have to replace the hot water recirculating pump in my house. It is made in Hungary and the Manufacturer's letters look almost Russian. The only words in English are the spec's (amp draw, voltage, etc.) This house was built in 1998 and the plumber's no longer in business. It looks like it just threads onto a quot;capbut I don't want to start using pipe wrenches and just mangle it (it's very difficult to get to also). Any help would be appreciated. Thanks, Mike

- Typically, such pumps come as an assembly with flanges to match the existing pipe. Determine your pipe-size and purchase the entire system to that size. Your plumbing supply will be able to help you match all that. And the difference in cost between just the pump cartridge and the entire system is nominal. Get a good one, by the way. Grundfos and Bell Gosset are amongst the best, TACO comes in pretty well also. Unless you have isolation valves on either side of this pump, you will have to drain the system to do it properly. While you are in there, you have the opportunity to install isolation valves and other sorts of refinements for easing future servicing. Hope this helps.

- Q: i took off the water pump cover on my 1986 cr 250 and discovered that the impeller wont come off. ive tried turnig it the wrong way and the right way. can someone please tell me how to get it off.

- Remove the water pump cover, Now you will see the impeller and it has a little 10 mm(I think) nut fitting on it. Put the bike in gear and apply the rear brake. Now unscrew the impeller with a socket wrench. Take it easy as they are quite soft. Once that is off, you should be able to pry the seal out, and pop a new one in. A good way to get old seals out is to use a screw, screw it in to the seal then grab it with the pliers. You might want to replace the oil seal while you are there since they are so cheap. To do this though you will have to remove the rh crank case cover cause this seal sits in the inside of this cover. This is also an easy job. When you remove the rh crank case cover ( with impeller already removed) the water pump shaft should just slide out from the inside and give you easy access to both seals.

- Q: I own a 2003 Kia Sorrento and recently I was driving and the car completely died. I had it towed to the dealership and the said that the engine was gone because the water pump failed causing the timing belt to snap. Does this sound right? I feel like I am being duped. They want 4,800 to fix I also owe 7,400 on the car. The timing belt was replaced 3 months ago. Could this be their error? Does anyone know how the water pump would affect the engine? HELP ME!

- Its a procedure to replace the water pump at the same time when the timing belt is replaced because both involve the same work, now , not all the mechanics follow this procedure, if the bearing in the water pump froze that is enough to cause mayor damage, they might be right , check your records if you were charged for water pump and belt then you have a case.

- Q: I have a 1.5 horse Power Hit and Miss engine? Is it possible to buy a water pump I could run off of the hit and miss engine that would pump water from a river over a big hill and little ways and into a water tank or is this just a waste of time. How much water could I pump at a time? A trickle or a gush of water? When I say hill I don't mean like a little hill in your yard I mean a hill you have to hike up? If you don't know are there any resources I could access? Where could I buy such a pump if there is one?

- A horse and a half won't do much. You would be better off with a hydraulic ram type pump if you can get about a 10 or 15 foot fall before the ram. It will pump about 4 or 5 times the height of the fall, but in small quantities. It will run 24/7 without gasoline, so it will fill a tank over a long period of time. The railroads used them during the steam era when they had huge water towers out on the plains.

- Q: We use this water pump for about 2 years, and in the last week the circuit breaker trip when we turn on the pump. What should I check first for the problem?

- It seems that your breaker has tendency become weak, first I would replace the breaker with a new one of the same amperage. You may have a filter on the supply pipe and if clogged it will draw more.

- Q: All of a sudden I have no water coming to the house/anywhere from the pump/well outside. It's a newer well, good water quantity (Florida...no dry up problems), no sand in water. I'm new to this house and don't know much about the pump stuff. Is there something I should look at or switch on/off. The breaker is ok. Help, I need a shower! :) Oh, there were about 15 ants around some box, but it didn't look connected to the pump...it's a box to the pool filter thing.

- If you are sure you have power to the unit, go to the pressure tank. There should be a pressure control switch with wires going in and out. It may have a reset switch that you can try to reset. You usually have to hold the switch for several seconds for the water pressure to build up past 20 pounds before you release the switch. You can tell if this is working by hearing water flow thru your pipes and/or watching the pressure gauge on the unit.

- Q: Okay, the fan has the clutch unit on the front with the large nut attaching it to the water pump. Then 4 screws attach the pulley to the water pump as well. What's the best way to immobilize pulley/pump so I can get the fan blade clutch nut unscrewed? Can't hold onto the fan or clutch unit since it simply spins. Can't realy seem to hold onto the pulley either as it prefers to spin? Any suggested best ways?

- First remember this tighten is loosen and loosen it tighten with the big nut on the fan clutch. And there is a tool you can buy (BMP design and Bavarian autosport have them) but I never bought one because I only could have used it once, and I try to keep my tool box as empty as I can. All this with the belt on..Get the biggest screwdriver you have and a heavy hammer. Now put the screwdriver on the tighten side one of the flat sides edge. Take hammer and give it a big wack. As long as the last guy put the fan clutch on right it should take no more than 2 tries to loosen it. Once its loose just spin it off by the fan blades and pull it out. I only once had to use a sawsall (only time I could have used the tool)on both the water pump and fan clutch to do a water pump job and after inspection I found some moron used lock tight. When you reinstall just spin it on and that's it no need to tighten.. I like to put antiseize on the bolt threads so I know the next time I have to remove the fan it will come off like buttahr...

Send your message to us

Centrifugal Slurry Pump for Mining and Water

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords