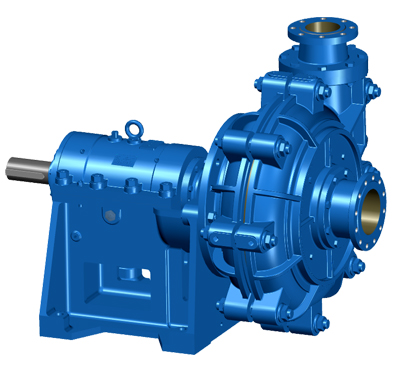

Slurry Pump for Mining Indurstry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

ZS series slurry pump is developed to be of the advanced world level based on 40 years of pump manufacturing and abundant trash pump technology,fully analyzing its different field operation requirements for different industrial applications,introducing the most advanced design theory and collecting the trade talents at home and abroad.

The slurry pump is characterized by its high efficiency,rational structure,high reliability,easy maintenance and low operation cost.It is widely applied to transport slurry containing solid particles in coal,electric power,metallurgy,chemical industry,etc.The maximum volume density for the solid mixed liquids:Cv≤30%,and its weight density is Cw≤60%.The flow passage is wide,and its flow capacity is great.

Application Area

Mines:For the feeding of ferrous and non-ferrous ore pulp and transportation of various concentrate pulp and reject pulp etc.

Metallurgy:For the transportation of various slime in aluminum plant(containing high-temperature slime,≤106℃),and the transportation of various slurry in steel plant.

Coals:For coal exploitation and transportation of various coarse、fine coal slurry(middlings and cleaned coals,etc) for washing.

Electricity:For electrical plant removing ash or ash- flushing,and the transportation of various ashes、mortars,etc.

Construction materials:For the transportation of various sand slurry(For instance,cement mill slime),etc.

Chemical industry:For the transportation of various chemical abrasive and corrosive slime(For example:phosphate fertilizer,potash fertilizer and so on.)

Environmental protection:For stack gas desulfurization and transportation of varous abrasive and corrosive slime.

Hydraulic engineering:For the dredging of pools and waterway,and pumping of sand,grit and clays,etc.

Performance Range

Outlet diameter: DN=25~300mm

Capacity: Q=44~2200m3/h

Head: H=16~116m

Speed: n=490、590、740、980、1480r/min

Permissible series connection working pressure: 2MPa

Matched power:P=5.5-800kW

- Q: What are the meanings of the vacuum pump, the front pump and the main pump?

- The main pump and the front pump with the general vacuum unitThe front pump can be understood as a mechanical pump. It can be used by itself, but the pumping rate or the vacuum can not meet the requirements. In this case, we add a booster pump

- Q: What is the difference between swashplate pump and crankshaft pump?

- Swash plate pump motor is driven as a coaxial swash plate drive plunger pump crankshaft work produces high pressure water in general simply and motor rotor to form a 90 degree angle of the motor through the crankcase to drive the piston to work in general the crankshaft speed is relatively high in the 2800 turn left and right to use the cost of the swash plate speed the use of less than 300 kg pressure in about 1400 when the crankshaft is relatively high but in more than more than 300 kilograms of crankshaft pump highlights the advantage of his adopted lookout!!!

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- Such as a large pressure of about 10m or about 0.1MPa} because the most unfavorable point fire hydrant requires more than 0.07MPa (7m) and 0.5MPa (50m) is not greater than the pressure, so unless the pump is located in the 50m Valley is still lower than the garage, or add to the valve (or the use of fire hydrant decompression) otherwise, it is 120m lift pump

- Q: How does the centrifugal pump pump and cut the pump?

- Can not be generalized, the pump is divided into many categories, centrifugal, reciprocating, screw type, diaphragm type, and so on, the starting steps of each pump is not the same. The following is the centrifugal pump and reciprocating pump to do a simple introduction. Check the items and so on.Centrifugal pump: first open the pump inlet valve, pump exhaust, and then start the motor, slowly open the outlet valve. If it is a high speed motor or multi-stage pump, open the motor before the outlet valve slightly open.Reciprocating pump: slightly open the inlet valve of the pump, fully open the outlet valve. After starting the motor, at the fully open inlet valve.Here is a brief introduction. I hope it works for you.

- Q: How to install, operate and maintain the pipeline booster pump?

- When the pump leaks, check it immediately to prevent leakage. If it leaks with the motor connection, replace the mechanical seal. Check that the power is connected. Is the supply voltage consistent with the operating voltage of the pump?. If the above a and B are normal, please remove the pump, open the pump cover, remove the foreign body in the pump, and then pump the lid on, and then tighten it to normal.No water pump, pump installed in the tap water pipeline, such as tap water level in the pump impeller on the plane (horizontal installation) or center line (vertical) below, you should turn off the power supply, to tap water level rise more than the impeller plane or the center line, connected to the power supply, to avoid mechanical damage (automatic no need to turn off the electric type). When the pump used in pumping wells, please check whether the water inlet pipe leak; pump cavity storage is not enough, should be filled with water, whether the suction process is too high, proper adjustment. Check whether the inlet and outlet diameter is too small or blocked. Automatic type after a period of time, there may be automatic failure phenomenon, mainly stainless steel and other metal products in pipes, long-term precipitation to shut off the power supply after unloading, unscrew the top screw, remove the plastic sheet to be cleaned, and then, according to the original reset, the normal debugging, can be re used.

- Q: Advantages and disadvantages of centrifugal pumps?

- The centrifugal pump has no valve, so it is suitable for conveying suspended liquid, and the special design can also transport large solid suspensionThe pump can be made of chemical resistant material, which is suitable for conveying corrosive solution.The utility model has the advantages of simple structure, few parts, little failures, durability, low maintenance cost, convenient management and reliable work.The output can be adjusted even by the discharge valve fully closed, there is no danger of infinite rising pressure head.The liquid is transferred to a large quantity. And the pressure head does not require large, most suitable for centrifugal pump.

- Q: What is the pumping property of concrete?

- Pumping capacity means that fresh concrete can be transported by concrete pump, and concrete construction can be carried out with high efficiency. 'pumping' is a qualitative statement

- Q: Why is the flow of the pump too small will occur cavitation phenomenon?

- This is because the impeller of the centrifugal pump rotating speed under the drive of the prime mover, when the valve opening decreases, flow rate is too low, can not be taken away by the friction heat generated by the impeller and the liquid completely, make the temperature of the liquid inside the pump. Thus causing liquid vaporization, forming cavitation. Especially in the power plant, the boiler feed pump is more remarkable. Therefore, when throttling regulation, we should set up recirculation system, increase the output flow of the pump to prevent cavitation. When the feed water rate is reduced to 1/3 of the maximum flow rate, the recirculating gate shall be opened so that the flow of the feed pump will be increased properly to ensure that the liquid temperature in the feed pump does not rise.

- Q: What is an industrial water pump?

- The pump has the different uses, conveying different liquid medium, different flow rate, different lift range, therefore, its structure of course is not the same, the material is different, in general, can be divided into:1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Do you have a suction pump higher than 9 meters?

- This screw self-priming pump suction process can be more than ten meters or more, my family is using this

Send your message to us

Slurry Pump for Mining Indurstry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches