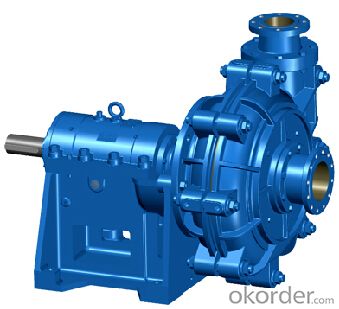

Horizontal Centrifugal Double Suction Water Pump

1.Structure of Horizontal Centrifugal Double Suction Water Pump Description

Horizontal Centrifugal Double Suction Water Pumpis used for transporting pure water (particles density shall be max.1%by volumeand granular size shall be max 0.1mm in dimeter) of the liquids with physical and chemical properties similar to pure water. Type MD pump is applied with wear resist material, especially suitable for mineral drainage. The particles density shall be max. 1.5% (Max. of the granular diameter is 0.5 mm).The liquid temperature ofD, MD pumps shall be lower than 80°C.

2.Main Features of the Horizontal Centrifugal Double Suction Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3.Horizontal Centrifugal Double Suction Water Pump Specification

Item | Multistage Pump |

Multistage Pump | Horizontal Multistage Pump For Pure Water |

Model | CMD |

Material | Cast iron,Stainless steel |

Mode | Horizontal |

Color | Blue |

Temperature | <=80°c< span=""><> |

Seal | packing seal |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Hot and cold pure water |

Outlet Diameter | 40-500mm |

Capacity | 6-1250 m3/h |

Head | 75-1800m |

Rotation Speed | 1450-2950r/min |

Power | 5.5-2400kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

4.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.