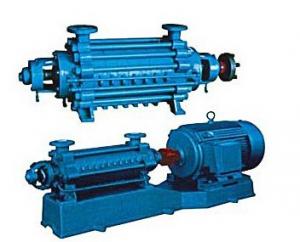

Boiler Feed Pump MD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Boiler Feed Pump Brief

This pump is horizontal sectional multistage centrifugal pump,due to high pressure and big flow ,widely application for boiler feed industrial,mining,water supply for high bulding,water circulation system,oil field ,etc

Because of different design,it can be divided into five type pumps:

1.D series pump:the medium temperature is not exceed 80°C, applicate to supply and discharge water for high buildings, resident,mine,fire fighting, pressure boosting and refrigeration water circulation for air conditioning, etc.

2.DG series boiler water feed pump:medium temperature is not exceed 160°C, applicate to transport hot water, such as water feed to bolier, municipal and industrial heating system.

3.DY multi-stage centrifugal oil pump: transport oil and oil product without solid at temp range -20—105°C, viscosity is less than 120.C.S.T

4.DF series stainless steel anti-corrosive multi-stage centrifugal pump: transport corrosive liquids without solid at -20—105 °C

5.DM series wearable mining multi-stage centrifugal pump: applicate to transport mining water with particles <1.5%,size<1mm, -20--105°C..

Boiler Feed Pump Parameter range:

Rated flowrate: 6-1000m3/h

Rated head: 40-2000m

Rotate speed: 3500r/min,2900r/min, 1750r/min,1450r/min

Cycle:50Hz/60Hz

Bearing Specification

Pump Model | D6-25 | D12-25 | D25-30 | D25-50 | D46-30 | D46-50 | D85-45 | D85-67 | D155-30 | D155-67 | D280-65 | D450-60 |

Bearing specification | N306 | N306 | N307 | N308 | N307 | N308 | N309 | N312 | N312 | N313 | N320 | N320 |

Bearing qty | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Boiler Feed Pump Structure Introduce

1.This series multi-stage pump have two bearings on begin and end shaft, flexible pin coupling coupled between pump and motor,.the rotating direction seen from the motor is clockwise

2.Horizontal suction and vertical discharge,but the DG pump are both vertical.Multi-stage pump 3.The bearing is lubricated by butter.

4.Shaft seal:Gland packing seal /mechnical seal

- Q: Does the water pump and the circulating pump belong to the centrifugal pump?

- As long as the flow and head to meet what pump can be, the general centrifugal pump applications are more.

- Q: HiThe well in my house is around 60 feet(20 meter). And the tank is 10 meter above the ground. My pump is Kirloskar Jet 1.5HP . It use to fill 500 Liter tank in 20 minutes. But now a days it is taking around 45 minutes to fill in. The pump is around 10years old. But it sounds good. Is it a problem with Pump or something else like Foot valve, Pipe, Pressure adjustment etc? . Do I need to change the pump? Which one is best suit for my well?. Submersible or Jet or something else?

- It's possible that your pipes are closing in and it's possible that the screen in your well is clogging up or the inpeller is going bad. Do you have a holdin tank above ground? and is it an aerator as well ? You may even have cloogged diverters or sprayers

- Q: I have had this water pump changed 2 times in 5 years is this normal for this car? It has a v6 motor.

- no it is not normal for most cars but maybe yours it is..

- Q: just changed the water pump on my lower unit installed the lower unit and started motor now there is no water coming out of the upper flow tube is it becouse the engine is not warmed up yet or is something not lined up ...........

- It shouldn't take long for the water to come out. Make sure the site tube isn't plugged up. If not, check your installation out.

- Q: What are the export pumps packed in cartons?

- Upstairs said the basic right, but only limited to the domestic, export also put the pump's wooden case (frame) into the carton.

- Q: Here is the deal...*Van over heats*Blows Cold quot;heatquot;*Added coolant and water (nothing happened)*Started van, felt the hoses (no h2o flowing thru)I really think my water pump is out, but I am not sure. Does this sound like my water pump. If so, I plan on changing it myself, how do i find step by step instructions to do so.... I have never done it before, but I cant afford to take it to a mechanic! Thanks for your help!

- Will is right. No sense in throwing away money on a water pump if that isn't the problem, your next question here would start off with.....I changed the water pump and still have the same problem..... Take it to a shop you trust, let them tell you what is wrong with it, if you choose to fix it yourself, invest in a Haynes manual. They have the step by step instructions you are looking for. Sounds to me like it is your thermostat though, as a rule, when water pumps go out, they leak, the impellers (the blades that actually pump the water) RARELY give out before the bearings or seals do. IF you choose to start replacing parts without getting it to shop, start with the thermostat. You might be pleasantly surprised.....:)

- Q: The water pump gasket in my '98 Forester (130k) recently began to leak, and I will be replacing it in the next couple days. I noticed a stream of bubbles in my overflow container, though, and am wondering if it might be bad head gaskets making the air bubbles. The bubbles only appear after the engine is warmed up, like after a drive around town - there aren't any bubbles when the engine is cold.Is it possible that these air bubbles are coming from the leaking water pump? I hope so, because I'd much rather replace the pump than the head gaskets!

- Yes it is from the leaky water pump. Because it is leaking it will most prob be sucking air. If it was a head gasket you would notice it when cold as well

- Q: I have a refrigerator that has the built in water dispenser and ice maker but it is in a location that does not have a water source, i would like to set up water tank to pump into the fridge but not sure what type of pump or system is needed to accomplish this i know the fridge does not have one built in, it needs the line pressure to circulate the water.any help would be great, thank you

- Of course this can be done, not cheaply but, it can be done. Your going to have to by an X-tol tank about one gallon then a small pump, one that can handle the amount of pressure you'll need. Then, all that's necessary is the lines to the fridge.

- Q: Why is the water pump usually used multi-stage pumps, while the circulating pump is usually a single-stage pump?

- Mainly determined by the function of the water supply pump and the circulation pump.Replenishment pump is mainly to supplement the loss of the system, so the general flow is smaller, larger head, single pump water model in a small flow situation, many are not up to the required head, can only use multi-stage pumps.Circulating pumps are generally large flow, low lift, heavy efficiency, economic operation, and hydraulic model point of view, are single-stage pumps more appropriate, especially single stage double suction pump.

- Q: I bought a salt water filter system for my inflatable pool(14' X 40deep) and filled it up with 80 pounds of salt as the directions call for. Unfortunately Intex did not design the pump correctly and it leaks.There is supposed to be some copper ion exchange with the water as it goes through the system. I returned the salt water system. Since salt is a natural bacterial fighter by itself, can I just add salt once in a while and keep the water salty and use the filter pump that came with the pool? You never see lakewater(which is a little salty) with algae in it unless it is stagnant. With a filter pump this would not happen as the water is being filtered frequently.

- I don't think you or others really understand a salt water chlorination unit. The salt is added to the pool water through water circulation of the pool water the ION unit water passes past these two electrodes which in turn give off a chlorine gas which becomes the chlorine requirements for the pool On the ioniser is a dial that is set to a required setting to do with the volume of certain sized swimming pools. Even though one has this unit connected to their pool, they still have to add chlorine to their pool of the chlorine level isn't enough. This can be done in various methods, via a floating skimmer or have pellets put in hair lint pot or scattered over the pool surface, once dissolved in a bucket of warm water. Just by leaving the salt in the water as you suggest won't really do much other than help keep the water salty! This is my opinion I'll not get into a wage or wars over who is right who is wrong! Your trying to get others on your side, because you made the wrong choice purchased a salty pool chlorinator pump your dis- satisfied with your choice I am not going to agree or disagree with your statement other that to say your putting your families health at risk being a skin flint! So you think your doing the right thing, by putting your families health at risk for the sake of a few lousy dollars. Do it properly have a professional to come connect it all up for youin a proper manner!! Surely your families health means a lot more to you than risking a few lousy bucks on the proper unit! Cheers!!

Send your message to us

Boiler Feed Pump MD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords