Instant Water Boiler Kettle

Instant Water Boiler Kettle Related Searches

Instant Boiling Water Kettle Water Boiler Kettle Electric Faultless Hot Water Bottle Hot Water Bottle With Hose Wearable Hot Water Bottle Kitchen Water Boiler Electric Hot Water Bottle Stopper Washer Wheat Filled Hot Water Bottle Cashmere Hot Water Bottle Extra Long Hot Water Bottle Old Fashioned Hot Water Bottle Lowest Price Electric Kettle Solar Powered Water Boiler Stainless Steel Double Boiler Hot Water Bottle Rite Aid Superhero Hot Water Bottle Hot And Cool Water Machine Boots Chemist Hot Water Bottles Hydronic Boiler Bio Boiler Hot Water Bottle Slippers Walgreens Hot Water Bottle Boiler Water Sample Cooler Stainless Steel Heater Buy Hot Water Bag Heart Shaped Hot Water Bottle boiler water sample cooler Teddy Bear Hot Water Bottle Electric Hot Water Bottle Argos Warm Water Underfloor HeatingInstant Water Boiler Kettle Supplier & Manufacturer from China

Instant Water Boiler Kettle is a versatile kitchen appliance designed to quickly heat and boil water for various purposes. This efficient and convenient device is perfect for making tea, coffee, or instant meals, as well as for cooking and other household needs. The kettle's compact design and user-friendly features make it an ideal choice for both home and office use.The Instant Water Boiler Kettle is widely used in various settings, such as homes, offices, hotels, and restaurants, where quick access to boiling water is essential. Its ability to heat water rapidly saves time and energy, making it an eco-friendly option as well. Users can easily control the temperature and volume of water, ensuring that their beverages and food are prepared to perfection.

Okorder.com is a reputable wholesale supplier of Instant Water Boiler Kettles, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com ensures that each Instant Water Boiler Kettle is manufactured to meet the highest standards of performance and durability. By partnering with Okorder.com, customers can enjoy the convenience of purchasing their Instant Water Boiler Kettles directly from a reliable source, ensuring that they receive the best value for their investment.

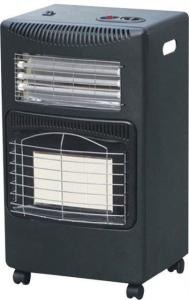

Hot Products