Reinforcing Retaining Wall

Reinforcing Retaining Wall Related Searches

Retaining Wall Geogrid Retaining Wall On Slope Mesh Retaining Wall Geogrid Retaining Walls Using Geogrid Retaining Walls Retaining Wall With Geogrid Geogrid For Retaining Wall Geogrid In Retaining Walls Retaining Soil Geogrid Reinforced Earth Wall Geogrid Fabric Retaining Wall Reinforcement Material Soundproofing A Wall Geogrid Reinforcing Fabric Reinforce Fabric Geogrid Base Reinforcement Grp Reinforcement Geogrid Reinforced Slope Geogrid Pavement Reinforcement Hydraulic Climbing Wall Geogrid Retaining Wall Cost Reinforcement Grid Recycled Insulation Geogrid Reinforced Foundation Residential Waterproofing French Door Retaining Hooks Slope Reinforcement Geogrid Geogrid Asphalt Reinforcement Waterproofing Wet Areas Retractable Walls CommercialReinforcing Retaining Wall Supplier & Manufacturer from China

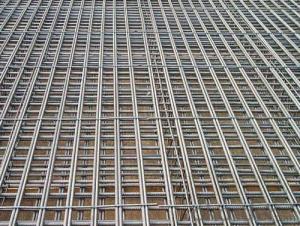

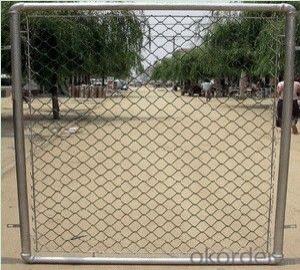

Reinforcing Retaining Wall is a specialized construction product designed to provide stability and support to retaining walls. These walls are crucial in various civil engineering projects, such as highway construction, bridge abutments, and slope stabilization, where the reinforcement is needed to prevent soil movement and maintain structural integrity.The Reinforcing Retaining Wall is widely used in scenarios where there is a need to retain soil and prevent erosion, ensuring the safety and longevity of the structure. This product is particularly beneficial in areas with challenging soil conditions or where there is a high risk of landslides. By incorporating the Reinforcing Retaining Wall into the design, engineers can create a more robust and reliable retaining wall system that can withstand the pressures of time and environmental factors.

Okorder.com is a leading wholesale supplier of Reinforcing Retaining Wall products, offering a vast inventory to cater to the needs of various construction projects. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Reinforcing Retaining Wall product meets the highest industry standards, providing contractors and engineers with the confidence they need to execute their projects successfully.

Hot Products