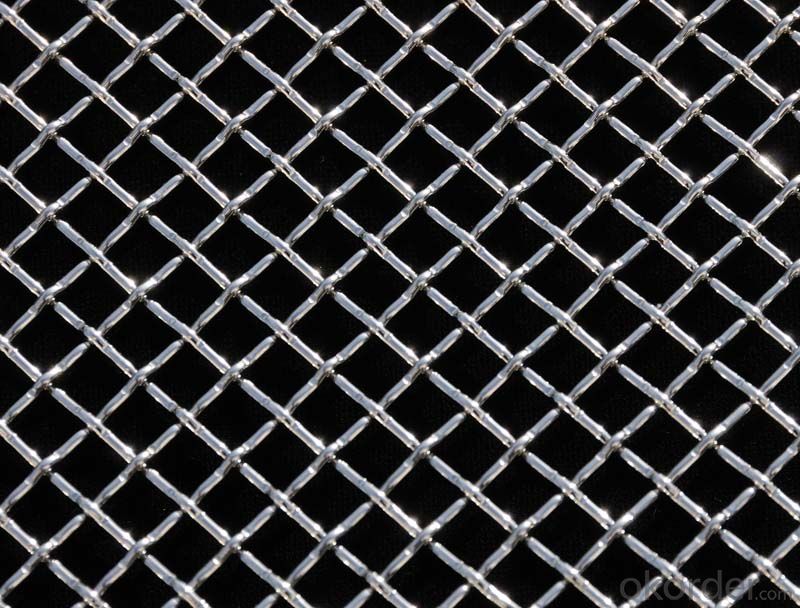

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GeneralInformation

GeneralInformation

Type: blank/uncoated, galvanized*, stainless steel, aluminum,copper, brass, plastic-coated

• Width of the grid: 400 – 2.200 mm

• Length of the grid: 300 – 7.000mm, or in roll form up to 50

• Dimensional tolerances in lengthand width: -0 mm /+1 mesh width (customary)

• On request fixed measures withtolerances of +/-2 mm in length and width

Galvanized double intermediate crimp screens aremanufactured from previously galvanized wire. The zinc coating is ca. 7 µm.Galvanized double crimp screens therefore are only limitedly suitable foroutdoor use.

Product Range

Weight of double intermediate crimp screens – in kg/m² | ||||||||||

Mesh width [mm] | Wire diameter [mm] | Crimps* | ||||||||

1,6 | 1,8 | 2,0 | 2,5 | 3,0 | 3,4 | 4,0 | 5,0 | 5,8 | ||

8 x 8 | 3,5 |

|

|

|

|

|

|

|

| 3 |

10 x 10 | 3,0 | 4,2 | 4,5 |

|

|

|

|

|

| 3 |

12 x 12 |

|

| 3,8 |

|

|

|

|

|

| 3 |

15 x 15 |

|

| 3,1 | 4,7 | 6,7 |

|

|

|

| 3 |

20 x 20 |

|

| 2,4 | 3,7 |

|

|

|

|

| 5 |

20 x 20 |

|

|

|

| 5,0 | 6,8 | 9,5 |

|

| 3 |

25 x 25 |

|

|

| 3,1 | 4,3 |

|

|

|

| 5 |

25 x 25 |

|

|

|

|

| 5,5 | 7,7 |

|

| 3 |

30 x 30 |

|

|

| 2,7 |

|

|

|

|

| 7 |

30 x 30 |

|

|

|

| 3,8 | 4,6 |

|

|

| 5 |

30 x 30 |

|

|

|

|

|

| 6,0 | 10,7 |

| 3 |

35 x 35 |

|

|

|

| 2,9 | 4,1 | 5,2 |

|

| 5 |

40 x 40 |

|

|

| 2,4 |

|

|

|

|

| 9 |

40 x 40 |

|

|

|

| 2,8 |

|

|

|

| 7 |

40 x 40 |

|

|

|

|

| 3,5 | 4,7 |

|

| 5 |

40 x 40 |

|

|

|

|

|

|

| 7,3 | 10,2 | 3 |

50 x 50 |

|

|

|

| 2,3 |

|

|

|

| 9 |

50 x 50 |

|

|

|

|

| 2,9 | 3,8 |

|

| 7 |

50 x 50 |

|

|

|

|

|

|

| 5,8 | 8,1 | 5 |

60 x 60 |

|

|

|

|

|

| 3,3 |

|

| 7 |

60 x 60 |

|

|

|

|

|

|

| 5,3 | 6,9 | 5 |

75 x 75 |

|

|

|

|

|

|

| 4,4 | 5,9 | 7 |

100 x 100 |

|

|

|

|

|

|

| 3,5 | 4,5 | 9 |

Application Areas

Our doubleintermediate crimp screens are used in the following fields as:

Safety grids (e.g. car industry,mechanical engineering, building industry)

Filling elements for gates andfences in buildings and gardens

Booth construction

Plant breeding

Pigeon barriers

Noise protection

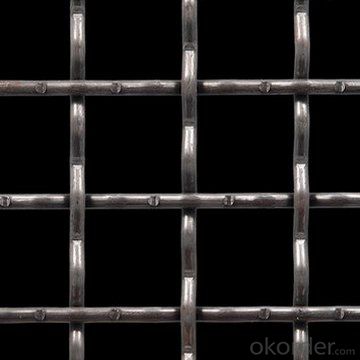

Lock crimp/Lock-Crimp Weave/Scalping Weave

Slotted screens (against flow)

Flat top screens with aone-sided plane surface have their chain and weft wires in plane position atthe intersection points due to the single-sided crimp of the wire. This methodgenerates a grid with a plane, unbroken bottom side.

General Information

Type:blank/uncoated, galvanized*,stainless steel, aluminium, copper, brass.

• Width ofthe grid: up to 2.200 mm

• Length ofthe grid: up to 5.000 mm or in roll form up to 50 m

•Dimensional tolerances in length and width: -0 mm /+1 mesh width (customary)

• Onrequest fixed measures with tolerances of +/-2 mm in length and width

The nominal size of the flat top screen always specifiesthe mesh width (=inner width).

Application Areas

Weight of flat top screens with a one-sided plane surface – in kg/m² | |||||

Mesh width [mm] | Wire diameter [mm] | ||||

2,0 | 2,5 | 3,0 | 4,0 | 5,0 | |

8 x 8 | 5,2 |

|

|

|

|

10 x 10 | 4,3 |

|

|

|

|

12 x 12 | 3,7 |

| 7,7 |

| 18,9 |

13 x 13 |

| 5,2 |

|

|

|

15 x 15 | 3,0 | 4,7 |

|

|

|

16 x 16 |

|

| 6,1 | 11,0 |

|

20 x 20 | 2,3 | 3,5 | 5,0 |

|

|

25 x 25 |

|

| 4,1 | 7,3 |

|

30 x 30 |

| 2,7 | 3,5 | 6,2 |

|

40 x 40 |

|

| 2,7 | 4,5 | 7,5 |

50 x 50 |

|

| 2,4 | 3,6 | 5,8 |

60 x 60 |

|

|

|

| 4,9 |

75 x 75 |

|

|

|

| 4,0 |

Flat topscreens with a one-sided plane surface are used in all fields where constantmesh width and the advantage of a one-sided plane surface are required, e.g.shelves, cage bottoms, support grids for filter fabric, stackable bin walls,security and cover grids. Flat top screens are becoming more and more importantas creative element in the architectural sector (e.g. as cladding for walls andceilings.)

Hook Strips for Screen Sections | ||

|

| Standard Hook Strip, Type 21, for side tensioning |

|

|

|

| Standrad Hook Strip, Type 21, for end tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for side tensioning | |

|

|

|

| Double Fold Hook Strip, Type 30, for end tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for side tensioning | |

|

|

|

| Welded-on Hook Strip for Screens, for end tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for side tensioning | |

|

|

|

| Welded-on Hook Strip for P-S-Screen, Type 24, for end tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

| Flat Tensioning Bar, Type 26A, for side tensioning | |

|

|

|

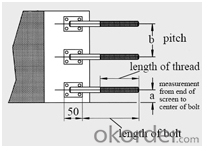

Tensioning Bolts | ||

| Flat Tensioning Bar with tensioning bolts. Please indicate measurements a + b and length of bolt. | |

- Q: Is steel wire mesh fire-resistant?

- Yes, steel wire mesh is generally considered to be fire-resistant. Steel has a high melting point and does not easily catch fire or burn. Steel wire mesh is commonly used in various applications that require fire resistance, such as in construction, industrial settings, and fencing. It can withstand high temperatures and is often used as a protective barrier to prevent the spread of fire or to contain flames. However, it is important to note that the level of fire resistance may vary depending on the specific type and thickness of the steel wire mesh. It is always recommended to consult with manufacturers or industry experts to ensure that the steel wire mesh meets the required fire resistance standards for a particular application.

- Q: Is steel wire mesh suitable for architectural facades?

- Yes, steel wire mesh is suitable for architectural facades. It offers a variety of benefits such as structural strength, durability, and versatility in design. The mesh can be customized to create unique patterns and textures, allowing for creative and visually appealing facades. Additionally, steel wire mesh is low maintenance and can provide adequate ventilation and shading while still allowing natural light to penetrate.

- Q: Can steel wire mesh be used for creating safety barriers?

- Steel wire mesh is a suitable option for the creation of safety barriers. Known for its strength and durability, steel wire mesh is an ideal choice in situations where safety is of utmost importance. It finds utility in diverse settings, including construction sites, industrial facilities, sports venues, and highways. Employing steel wire mesh barriers effectively prevents unauthorized access, shields pedestrians from falling objects, and regulates vehicle movement. Moreover, these barriers are robust enough to endure adverse weather conditions and potential impacts. In addition, steel wire mesh barriers are cost-effective, require minimal maintenance, and can be easily installed and tailored to meet specific requirements. In conclusion, steel wire mesh is a dependable and adaptable material for the construction of safety barriers.

- Q: Can steel wire mesh be used for creating architectural facades?

- Yes, steel wire mesh can be used for creating architectural facades. Steel wire mesh offers numerous benefits for architectural applications, making it a popular choice for designing facades. Firstly, steel wire mesh is extremely durable and can withstand harsh weather conditions, making it ideal for long-term use. It is also highly resistant to corrosion, ensuring the facade remains intact and visually appealing for many years. Additionally, steel wire mesh provides excellent transparency, allowing natural light to pass through and creating a visually dynamic effect. It can also be customized in terms of patterns, sizes, and finishes, offering architects and designers a wide range of options to create unique and aesthetically pleasing facades. Moreover, steel wire mesh is lightweight yet strong, making it easy to install and reducing the structural load on the building. Its flexibility also allows for different forms and shapes to be created, enabling architects to explore creative and innovative designs. Overall, steel wire mesh is a versatile and durable material that can be effectively used to create stunning architectural facades.

- Q: Can steel wire mesh be used for reinforcement in concrete?

- Indeed, reinforcement in concrete can be achieved through the utilization of steel wire mesh. Commonly employed as a reinforcement material in concrete structures, steel wire mesh serves to augment both their strength and durability. By averting cracks and bolstering resistance against tension and bending forces, it furnishes supplementary support to the concrete. Typically, the steel wire mesh is incorporated within the concrete during the pouring stage, generating a grid-like configuration that fortifies the entire structure. As a result, this reinforcement aids in the uniform distribution of the load and enhances the overall structural integrity of the concrete.

- Q: What are the potential disadvantages of using steel wire mesh?

- Some potential disadvantages of using steel wire mesh include its susceptibility to rust and corrosion over time, the possibility of sharp edges or protruding wires causing injury, its relatively high cost compared to other materials, and its limited flexibility and ability to conform to irregular shapes or curves. Additionally, steel wire mesh may not be suitable for applications that require lightweight or non-conductive materials.

- Q: What are the different wire diameters used in steel wire mesh?

- Different applications and requirements call for a variety of wire diameters in steel wire mesh. Steel wire mesh can have wire diameters ranging from as small as 0.5mm (0.02 inches) to as large as 6mm (0.24 inches). However, it should be noted that the wire diameters used can vary depending on the intended use and the design of the mesh. For lighter applications such as insect screens or decorative purposes, wire diameters typically range from 0.5mm to 2mm (0.02 to 0.08 inches). These thinner wires provide the necessary strength and stability while still allowing for good visibility and airflow. In medium-duty applications like fencing or security barriers, wire diameters usually range from 2mm to 4mm (0.08 to 0.16 inches). These slightly thicker wires offer increased strength and durability to withstand external forces or potential intruders. For heavy-duty applications such as industrial machinery or reinforcing concrete, wire diameters typically range from 4mm to 6mm (0.16 to 0.24 inches). These thicker wires provide maximum strength and stability, making them suitable for demanding environments and high-load situations. Consulting with manufacturers or suppliers is important to determine the appropriate wire diameter for specific applications. Factors such as load requirements, environmental conditions, and desired mesh properties should be taken into consideration to ensure the right wire diameter is selected for optimal performance and longevity.

- Q: What are the different mesh shape options available for steel wire mesh?

- Steel wire mesh offers a variety of mesh shape options, each with its own unique characteristics and advantages. Here are some of the most common options: 1. Square Mesh: This is the most widely used option, featuring square openings formed by intersecting wires at right angles. It provides equal strength in both directions and is commonly used for filtration, screening, and reinforcement. 2. Rectangular Mesh: Similar to square mesh, this option has rectangular-shaped openings that allow for different dimensions in the horizontal and vertical directions. It offers versatility for applications such as partitions, fencing, and architectural designs. 3. Diamond Mesh: Also known as rhomboidal mesh, this option has diamond-shaped openings formed by diagonal wires. It offers excellent structural stability and is often used for security fencing, animal enclosures, and gabion walls. 4. Hexagonal Mesh: Also called hex mesh or chicken wire, this option features hexagonal-shaped openings formed by continuous wires. It provides flexibility and is commonly used in agricultural applications such as poultry enclosures, garden fencing, and small animal cages. 5. Welded Mesh: This type of mesh is created by electrically welding the intersection points of the wires, resulting in a rigid and durable shape. It offers high strength and is widely used in construction, concrete reinforcement, and infrastructure projects. 6. Expanded Metal Mesh: Produced by cutting and stretching a sheet of metal, this option creates a pattern of interconnected diamond-shaped openings. It offers excellent visibility, ventilation, and light transmission, making it suitable for walkways, catwalks, and grating. These are just a few examples of the many mesh shape options available for steel wire mesh. The choice depends on specific requirements, including strength, durability, visibility, and aesthetics.

- Q: How does the color affect the visibility of steel wire mesh?

- The color of steel wire mesh can have an impact on its visibility, although it is not the primary factor. The visibility of steel wire mesh primarily depends on its size, pattern, and the environment in which it is placed. However, color can play a secondary role in determining how visible the mesh is. In general, lighter-colored steel wire mesh, such as silver or white, tends to be more visible in darker environments. This is because lighter colors reflect more light, making the mesh stand out against its surroundings. On the other hand, darker-colored steel wire mesh, such as black or dark gray, may blend in more easily in low light conditions or when placed against dark backgrounds. However, it is important to note that color alone does not determine the visibility of steel wire mesh. Mesh size and pattern, as well as the lighting conditions and background against which it is placed, have a more significant impact on its visibility. For example, a larger mesh size with a distinct pattern will be more visible regardless of its color. Furthermore, in certain specific applications, such as security fencing or architectural purposes, the color of steel wire mesh may be chosen to blend in with the surrounding environment or match the overall aesthetic. In these cases, visibility may not be the primary concern, and other factors, such as durability or design, may take precedence. In summary, while the color of steel wire mesh can influence its visibility to some extent, it is not the sole determining factor. Mesh size, pattern, lighting conditions, and background play a more significant role in determining the visibility of steel wire mesh.

- Q: How is steel wire mesh used in reinforcement of embankments?

- Steel wire mesh is commonly used in the reinforcement of embankments to provide stability and prevent erosion. The mesh is typically placed within the embankment structure to distribute the load and improve its overall strength. When constructing embankments, such as those found in roadways, railways, or retaining walls, steel wire mesh is often incorporated as a reinforcement measure. The mesh is made up of interlocking strands of steel wire, forming a grid-like pattern. This grid acts as a reinforcement layer that enhances the embankment's resistance to external forces, such as the weight of the soil, water pressure, or ground movements. The main function of steel wire mesh in embankment reinforcement is to distribute the load more evenly across the structure. By providing a continuous network of interconnected wires, the mesh helps to transfer the load from the surface to the underlying layers, reducing the risk of localized failures or deformations. This is especially important in areas with weak or unstable soils, where the mesh can help to stabilize the embankment and prevent settlement or collapse. Additionally, steel wire mesh can also serve as a barrier against erosion. It helps to retain the soil particles within the embankment, preventing them from being washed away by water or wind. This is particularly crucial in embankments located near rivers, streams, or coastal areas, where the risk of erosion is higher. The use of steel wire mesh in embankment reinforcement offers several advantages. It is a cost-effective solution compared to alternative methods, such as using concrete or geosynthetic materials. Steel wire mesh is also relatively easy to install and can be customized to fit the specific requirements of the embankment project. Furthermore, its durability and resistance to corrosion ensure a long lifespan, providing long-term stability and protection to the embankment structure. In conclusion, steel wire mesh plays a crucial role in the reinforcement of embankments. It enhances the embankment's strength, stability, and resistance to external forces, while also preventing erosion. Its cost-effectiveness, ease of installation, and durability make it a preferred choice for many embankment construction projects.

Send your message to us

Crimped wire screen for Mine

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches