Electric Redrawing Galvanized Hexagonal Wire Netting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

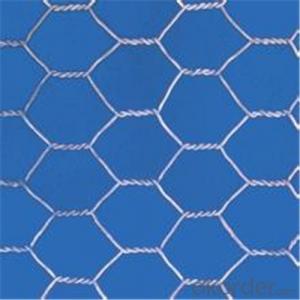

Introduction of Electric Redrawing Galvanized Hexagonal Wire Netting

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Electric Redrawing Galvanized Hexagonal Wire Netting

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Electric Redrawing Galvanized Hexagonal Wire Netting

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Electric Redrawing Galvanized Hexagonal Wire Netting

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Electric Redrawing Galvanized Hexagonal Wire Netting

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Electric Redrawing Galvanized Hexagonal Wire Netting

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for dewatering applications?

- Yes, steel wire mesh can be used for dewatering applications. It is commonly used as a filter medium to separate solids from liquids in various industries, such as mining, construction, and wastewater treatment. The mesh's open structure allows water to pass through while retaining solid particles, making it an effective tool for dewatering processes.

- Q: Can steel wire mesh be fire resistant?

- Yes, steel wire mesh can be fire resistant. Steel itself is a non-combustible material, meaning it does not catch fire or contribute to the spread of flames. When used in wire mesh form, the steel strands are typically woven or welded together in a way that creates small openings between the wires, allowing for air circulation. This design helps dissipate heat and prevent the buildup of intense heat in one area, reducing the risk of ignition or melting. Additionally, some steel wire mesh products are coated with fire-resistant coatings or treated with fire retardant chemicals to enhance their fire resistance properties. These coatings or treatments can further delay the spread of flames and provide additional protection against fire. However, it is important to note that the fire resistance of steel wire mesh may vary depending on factors such as the specific type of steel used, the construction method, and any additional fire-resistant treatments applied to the mesh. Therefore, it is always recommended to consult with manufacturers or fire safety professionals to ensure that the steel wire mesh meets the required fire resistance standards for a particular application.

- Q: Is steel wire mesh suitable for landscaping?

- Yes, steel wire mesh is suitable for landscaping in various ways. It can be used to create boundaries or enclosures, such as fencing or gates, to define different areas within a landscape. Steel wire mesh is strong and durable, making it an excellent choice for securing and protecting plants, trees, or garden beds from animals or other external factors. Additionally, it can be used as a support structure for climbing plants or vines, creating a visually appealing vertical garden. Steel wire mesh can also be utilized as a trellis or screen to provide privacy or shade in outdoor spaces. Furthermore, it can be used for erosion control by reinforcing slopes or retaining walls. Overall, steel wire mesh is a versatile and practical material for various landscaping applications.

- Q: Is steel wire mesh resistant to extreme weather conditions?

- Yes, steel wire mesh is generally resistant to extreme weather conditions. Steel wire mesh is made from high-quality steel, which makes it strong and durable. It can withstand harsh environmental conditions such as heavy rain, strong winds, and extreme temperatures. The steel construction of the mesh also ensures that it does not warp or lose its shape under stress. This makes it an ideal material for outdoor applications where it is exposed to extreme weather conditions. However, it is important to note that the level of resistance may vary depending on the specific grade and quality of steel used in the mesh. Additionally, proper installation and maintenance of the mesh are also crucial to ensure its long-term durability and resistance to extreme weather conditions.

- Q: What is the meaning of a lightweight wall hanging wire mesh?

- Glass bricks are generally used to make kitchen wall partition, waterproof, fire, light, whitewash suitable for use in the kitchen, bathroom, can withstand moisture and can bring natural light to the room. If you think the glass brick is too expensive to use other materials, but also pay attention to its waterproof performance, can be coated with waterproof coating or paste the tile to strengthen its waterproof.

- Q: What are the different wire mesh finishes available in steel wire mesh?

- There are several different finishes available for steel wire mesh, each offering unique properties and advantages depending on the intended use. Some of the most common finishes include: 1. Galvanized: This is the most common finish for steel wire mesh, where the wire is coated with a layer of zinc to prevent rust and corrosion. Galvanized wire mesh is highly durable and suitable for outdoor applications. 2. PVC Coated: In this finish, the wire mesh is coated with a layer of PVC (polyvinyl chloride) to provide additional protection against corrosion and enhance its aesthetic appeal. The PVC coating also adds an extra layer of insulation, making it ideal for applications where electrical conductivity needs to be minimized. 3. Stainless Steel: Wire mesh made from stainless steel offers excellent corrosion resistance and durability, making it suitable for harsh environments. Stainless steel wire mesh is commonly used in industries such as food processing, pharmaceuticals, and marine applications. 4. Epoxy Coated: This finish involves applying a layer of epoxy powder coating to the wire mesh, providing excellent chemical resistance and enhanced durability. Epoxy coated wire mesh is commonly used in industrial settings where resistance to chemicals, abrasion, and impact is required. 5. Blackened: This finish involves subjecting the wire mesh to a chemical treatment or heat process that darkens its appearance and provides a decorative or aesthetic appeal. Blackened wire mesh is often used in architectural applications or for decorative purposes. 6. Copper or Brass Plated: Wire mesh can also be plated with copper or brass to enhance its appearance and provide additional corrosion resistance. Copper or brass plated wire mesh is commonly used in decorative applications such as ornamental fencing or architectural features. These are just a few of the many different finishes available for steel wire mesh. The choice of finish depends on factors such as the intended application, environmental conditions, and specific requirements of the project. Consulting with a knowledgeable supplier or manufacturer can help determine the most suitable wire mesh finish for a particular application.

- Q: What are the different grades of steel wire mesh?

- There are several different grades of steel wire mesh, including low carbon steel wire mesh, high carbon steel wire mesh, stainless steel wire mesh, and galvanized steel wire mesh.

- Q: What is the average lifespan of steel wire mesh?

- The average lifespan of steel wire mesh can vary depending on several factors such as the quality of the mesh, the environment it is exposed to, and the frequency of use or maintenance. Generally, steel wire mesh is known for its durability and longevity, making it a popular choice for various applications. In ideal conditions, where the mesh is properly installed, protected from corrosion, and not subjected to excessive stress or wear, steel wire mesh can last for several decades. However, in harsh environments with exposure to corrosive substances, extreme temperatures, or frequent vibrations, the lifespan of the mesh may be shorter. Regular maintenance and inspection can significantly extend the lifespan of steel wire mesh. It is recommended to clean the mesh periodically to remove any debris or corrosive substances that may accumulate. Additionally, applying protective coatings or treatments can help prevent corrosion and enhance the mesh's longevity. Ultimately, the average lifespan of steel wire mesh can range from 10 to 50 years or more, depending on the aforementioned factors. It is important to consider these factors and consult with experts or manufacturers for specific applications to ensure the best possible lifespan for the steel wire mesh.

- Q: How does the thickness affect the strength of steel wire mesh?

- The strength of steel wire mesh is directly influenced by its thickness. With an increase in wire thickness, the mesh's strength also increases. This occurs because thicker wires possess a greater resistance to deformation, reducing the likelihood of breakage or bending under pressure. The added thickness enhances structural integrity and boosts the mesh's resistance against impacts or external forces. Consequently, thicker steel wire mesh typically exhibits greater durability and can withstand heavier loads or stresses. Conversely, thinner wire mesh is more prone to damage or failure, as it possesses less material to resist deformation.

- Q: Can steel wire mesh be used for agricultural cages?

- Yes, steel wire mesh can be used for agricultural cages. It provides a sturdy and durable structure that can effectively contain and protect animals or plants in an agricultural setting.

Send your message to us

Electric Redrawing Galvanized Hexagonal Wire Netting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords