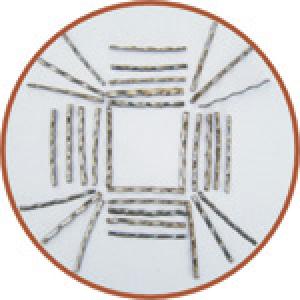

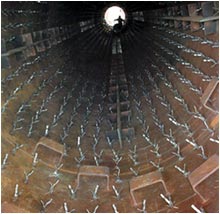

Refractory Anchor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Refractory Anchor

|

- Q: How do steel products contribute to the transportation industry?

- Steel products play a crucial role in the transportation industry as they are used extensively in the manufacturing of vehicles, infrastructure, and components. From cars, trucks, and trains to bridges, rails, and roads, steel provides strength, durability, and reliability. It helps in constructing lightweight yet sturdy frames, bodies, and chassis of vehicles, ensuring safety and efficiency. Additionally, steel is used in the production of bearings, gears, axles, and springs, enhancing the performance and functionality of various transportation systems. Overall, steel products contribute significantly to the transportation industry by providing the necessary strength, structural integrity, and reliability required for safe and efficient movement of people and goods.

- Q: What are the properties and characteristics of different steel products?

- The properties and characteristics of different steel products can vary depending on factors such as the grade of steel, its composition, and the manufacturing process used. However, some common properties and characteristics of steel products include: 1. Strength and Durability: Steel is known for its high strength and durability, making it suitable for applications requiring structural integrity and resistance to wear and tear. 2. Corrosion Resistance: Stainless steel products possess excellent corrosion resistance due to the presence of alloying elements such as chromium, which forms a protective layer on the surface, preventing rust and corrosion. 3. Versatility: Steel products are available in various forms, including sheets, bars, pipes, and tubes, offering versatility in terms of design and application possibilities. 4. Heat Resistance: Certain steel alloys, such as carbon steel, can withstand high temperatures without losing their structural integrity, making them suitable for applications in heat-intensive environments. 5. Formability and Weldability: Steel can be easily formed, shaped, and welded, allowing for customization and fabrication of products to meet specific requirements. 6. Weight-to-Strength Ratio: Steel has a favorable weight-to-strength ratio, meaning it can provide high strength while being relatively lightweight compared to other materials. 7. Recyclability: Steel is a highly recyclable material, making it an environmentally friendly choice as it can be reused and repurposed without losing its properties. It is important to note that the specific properties and characteristics of different steel products can vary depending on their intended use, manufacturing process, and any additional treatments or coatings applied.

- Q: What are the different types of steel fasteners and their uses in the marine industry?

- In the marine industry, there are several types of steel fasteners commonly used. These include stainless steel bolts, screws, nuts, washers, and rivets. Stainless steel fasteners are preferred in this industry due to their excellent corrosion resistance properties. Bolts are typically used in heavy-duty applications, such as securing large components or structural elements. Screws are commonly used for fastening smaller components, while nuts and washers are used in conjunction with bolts to provide additional stability and prevent loosening. Rivets are another type of fastener used in marine applications, particularly for joining thin sheets of metal. They provide a secure and permanent connection, ideal for areas with high vibration or where welding may not be feasible. Overall, these steel fasteners play a vital role in the marine industry by ensuring the structural integrity, safety, and longevity of various components and structures, even in harsh saltwater environments.

- Q: What are the different types of steel building systems?

- There are several types of steel building systems, including rigid frame, arch, modular, and clear span systems. Each type offers unique advantages and is designed to meet specific needs in terms of functionality, size, and design flexibility.

- Q: What are the different types of steel profiles used in machinery frames?

- There are several types of steel profiles commonly used in machinery frames, including I-beams, H-beams, C-channels, and angle irons. Each profile has its own unique shape and structural properties that make it suitable for specific applications in machinery construction.

- Q: What is the role of steel in the telecommunications industry?

- Steel plays a crucial role in the telecommunications industry as it is used to construct transmission towers and other supporting structures. These steel structures provide the necessary height and stability for antennas and other equipment to transmit and receive signals. Steel's strength, durability, and ability to withstand harsh weather conditions make it an ideal material for telecom infrastructure, ensuring reliable and efficient communication networks.

- Q: How are steel profiles used in the construction of underground tunnels?

- Steel profiles are commonly used in the construction of underground tunnels for structural support and stability. These profiles, typically in the form of beams or columns, are installed to reinforce the tunnel walls and prevent collapse. They provide strength and rigidity, helping to distribute the weight of the surrounding soil or rock and withstand external forces such as ground pressure. Additionally, steel profiles can be used to create the framework for tunnel formwork, allowing for the efficient casting of concrete walls or lining. Overall, steel profiles play a crucial role in ensuring the safety and durability of underground tunnels.

- Q: How is steel plate produced?

- Steel plates are produced through a process called steelmaking, where iron ore is melted in a blast furnace along with other elements like limestone and coke. This molten iron is then refined and converted into steel by removing impurities through various methods such as oxygen blowing or electric arc furnaces. The steel is then cast into slabs or billets, which are further rolled into desired thicknesses and shapes to produce steel plates.

- Q: What are the key characteristics of stainless steel?

- Some key characteristics of stainless steel include its high resistance to corrosion, its durability and strength, its low maintenance requirements, and its ability to withstand high and low temperatures. It also has a sleek and polished appearance, making it popular in various industries such as construction, automotive, and kitchenware.

- Q: How are steel products used in the marine and shipbuilding industry?

- Steel products are widely used in the marine and shipbuilding industry due to their strength, durability, and corrosion resistance. They are used to construct the hull, decks, bulkheads, and other structural components of ships and offshore structures. Additionally, steel is utilized in the fabrication of equipment, such as propellers, shafts, and anchoring systems. Its use in the marine industry ensures the safety and reliability of vessels, making it essential for shipbuilding and maritime operations.

Send your message to us

Refractory Anchor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords