Hot dipped Galvanized Hexagonal Wire Netting after Weaving for Chicken

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

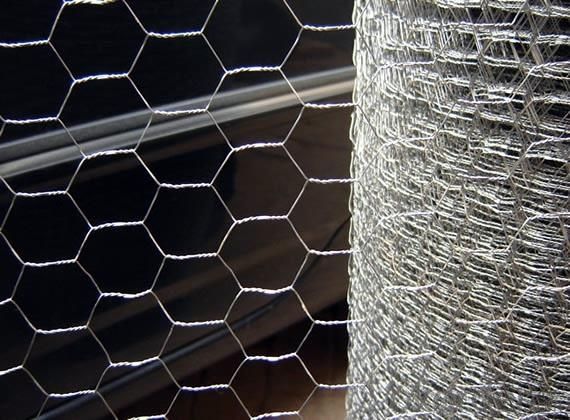

Introduction of Galvanized Hexagonal Wire Mesh after weaving for Chicken

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh for Chicken

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh after weaving for Chicken

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh after weaving for Chicken

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh for Chicken

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Galvanized Hexagonal Wire Mesh for Chicken

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Is steel wire mesh suitable for aquaculture applications?

- Yes, steel wire mesh can be suitable for aquaculture applications. Steel wire mesh is known for its strength, durability, and resistance to corrosion, which are all important factors in aquaculture settings. It can be used to create cages, enclosures, or fencing to contain and protect fish or other aquatic organisms. The mesh size can be customized to allow for water flow while preventing predators or escape of the farmed species. Additionally, steel wire mesh can be easily cleaned and maintained, ensuring a hygienic environment for the aquaculture operation. However, it is important to consider the specific requirements of the aquaculture system and the species being farmed to determine the most suitable mesh size and material.

- Q: Is steel wire mesh suitable for construction reinforcement?

- Construction reinforcement can be effectively achieved using steel wire mesh. This versatile material is highly adaptable and can be utilized in a wide range of construction applications, serving as a vital component in numerous projects. One of the main advantages of steel wire mesh is its ability to enhance the strength, stability, and durability of structures. This makes it an indispensable element in construction projects. Steel wire mesh finds extensive use in reinforced concrete structures like slabs, walls, and columns. Its effectiveness lies in its ability to improve the tensile strength of concrete, thus preventing cracks and increasing the load-bearing capacity of the structure. By evenly distributing applied loads, the mesh acts as a reinforcement, reducing the risk of failure. Moreover, steel wire mesh demonstrates excellent resistance to corrosion, making it particularly suitable for construction projects that are exposed to moisture or harsh environmental conditions. It can withstand high temperatures, impacts, and stresses, ensuring the longevity and structural integrity of the reinforced concrete. In addition to its numerous advantages, steel wire mesh is easy to install, resulting in time and labor savings during construction. It is available in various sizes and shapes, allowing for design flexibility and catering to diverse project requirements. Additionally, it is readily accessible and cost-effective when compared to other reinforcement materials, making it favored by construction professionals. In conclusion, steel wire mesh is a dependable and suitable choice for construction reinforcement. Its strength, durability, corrosion resistance, ease of installation, and cost-effectiveness make it an excellent option for improving the structural integrity and performance of various construction projects.

- Q: How is steel wire mesh used in reinforcement of pipes?

- Steel wire mesh is commonly used in the reinforcement of pipes to enhance their strength and durability. The mesh is typically made from high-quality steel wires that are woven or welded together to form a grid-like pattern. When the steel wire mesh is embedded in the pipe, it acts as a reinforcement layer that helps to distribute the load and stress evenly across the pipe structure. This reinforcement significantly improves the pipe's resistance to bending, cracking, and deformation, making it more suitable for heavy-duty applications. The steel wire mesh also helps to prevent the propagation of cracks and fractures in the pipe. In the event of a crack initiation, the mesh acts as a barrier and restricts the growth of the crack, thereby preventing further damage and potential failure of the pipe. Furthermore, steel wire mesh reinforcement can also enhance the pipe's resistance to external factors such as soil movement, temperature variations, and corrosion. The mesh provides additional strength and stability, enabling the pipe to withstand these environmental factors more effectively. In addition to its strength and durability benefits, steel wire mesh reinforcement also improves the overall performance of the pipe. The mesh enhances the pipe's load-bearing capacity, allowing it to withstand higher pressure and heavier loads. This makes it an ideal choice for applications that require high-performance pipes, such as in construction, infrastructure projects, and industrial applications. Overall, steel wire mesh plays a crucial role in the reinforcement of pipes by increasing their strength, durability, and resistance to various external factors. Its use in pipe reinforcement ensures the longevity and reliability of the pipe, making it a preferred choice in many industries.

- Q: What are the different wire gauges available for steel wire mesh?

- The different wire gauges available for steel wire mesh typically range from 6 to 20, with smaller gauges being thicker and larger gauges being thinner.

- Q: Can steel wire mesh be used for window and door screens?

- Certainly, window and door screens can utilize steel wire mesh. Steel wire mesh, a robust and enduring material, is widely employed in numerous applications, including window and door screens. It effectively blocks insects and undesirable elements while permitting the flow of air and light. Steel wire mesh screens are resistant to corrosion and can endure severe weather conditions, rendering them suitable for both indoor and outdoor purposes. Furthermore, these screens come in various mesh sizes and thicknesses, enabling you to select the most suitable option based on your specific requirements.

- Q: How is steel wire mesh used in reinforcement of food processing plants?

- Steel wire mesh is commonly used in the reinforcement of food processing plants due to its strength, durability, and hygienic properties. It is primarily used to reinforce the walls, floors, and ceilings of these facilities to ensure they can withstand the rigorous demands of the food processing industry. In food processing plants, steel wire mesh is typically installed in the form of welded or woven wire panels. These panels are made from high-quality stainless steel, which offers excellent resistance to corrosion, chemicals, and extreme temperatures. This makes it an ideal material for maintaining a hygienic environment in food processing facilities. One of the key uses of steel wire mesh in food processing plants is to create partitions or enclosures within the facility. These partitions separate different areas, such as processing, packaging, storage, and administrative spaces, to prevent cross-contamination and maintain strict hygiene standards. Steel wire mesh panels can be easily installed and customized to fit the specific layout and requirements of the facility. Another important application of steel wire mesh is in the construction of shelves, racks, and conveyor systems. These structures are used to store and transport raw materials, finished products, and equipment throughout the facility. Steel wire mesh provides a strong and stable platform for these operations, ensuring the safe and efficient movement of goods. Furthermore, steel wire mesh is often used to reinforce the flooring in food processing plants. The mesh is embedded within the concrete or epoxy resin to enhance its structural integrity and prevent cracking or damage. This is especially crucial in areas where heavy machinery, forklifts, or pallet jacks are used, as it helps distribute the load and prevents the floor from deteriorating over time. Overall, the use of steel wire mesh in the reinforcement of food processing plants is essential for maintaining a clean, safe, and efficient environment. It provides the necessary strength, durability, and hygiene required in these facilities, ensuring compliance with stringent industry regulations and delivering high-quality food products to consumers.

- Q: Can steel wire mesh be used for creating safety barriers?

- Yes, steel wire mesh can be used for creating safety barriers. Steel wire mesh is durable, strong, and provides excellent visibility and ventilation. It can effectively deter unauthorized access, prevent falls or accidents, and ensure the safety of people in various settings such as construction sites, warehouses, or sports facilities.

- Q: How is steel wire mesh used in reinforcement of infrastructure projects?

- Steel wire mesh is commonly used in the reinforcement of infrastructure projects as it provides strength and stability to concrete structures. It is typically embedded within the concrete to enhance its tensile strength, preventing cracking and improving the overall durability of the infrastructure. The wire mesh acts as a reinforcement layer, distributing the load and reinforcing the concrete against external forces such as heavy loads, seismic activity, and temperature fluctuations. This helps to ensure the longevity and structural integrity of the infrastructure project.

- Q: How does steel wire mesh perform in chemical resistance?

- Steel wire mesh generally performs well in chemical resistance. It is highly resistant to corrosion and can withstand exposure to various chemicals, acids, and alkalis. However, the specific performance may vary depending on the type of chemical and concentration. It is recommended to consult with manufacturers or experts to ensure the appropriate selection of steel wire mesh for specific chemical applications.

- Q: How does steel wire mesh perform in terms of visibility and transparency?

- Due to its dense construction and solid structure, steel wire mesh is generally characterized by low visibility and transparency. The interweaving of steel wires forms a solid barrier that hinders the view and restricts the passage of light. This lack of transparency makes it ideal for situations where privacy and security are of utmost importance, including fencing, partitions, and window screens. However, if the objective is to optimize visibility or enable abundant natural light to pass through, alternative materials such as glass or transparent plastics would be more appropriate choices.

Send your message to us

Hot dipped Galvanized Hexagonal Wire Netting after Weaving for Chicken

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords