Road Wall Reinforcement Mesh from Basalt Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6500 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforcemet Mesh from Basalt Fiber Introduction

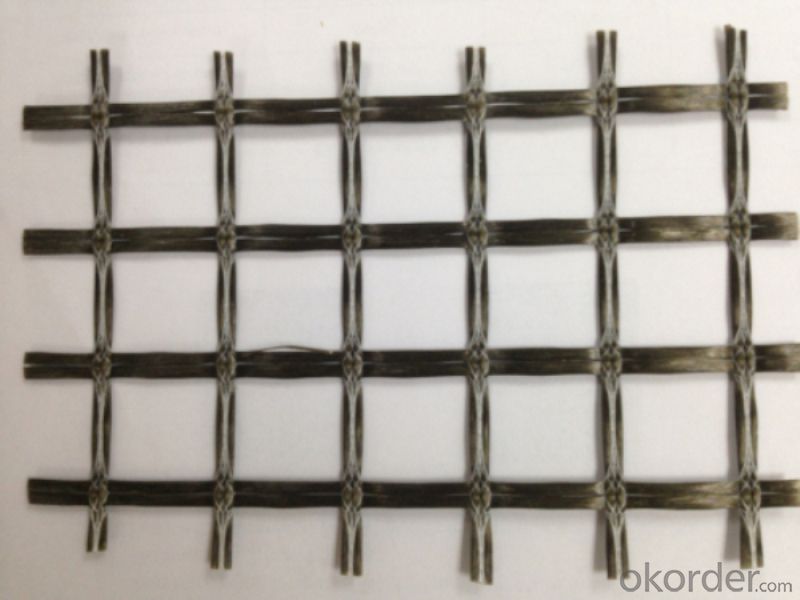

Continuous basalt fiber mesh is made by impregnating woven basalt fiber scrim with asphalt and then drying to be made.

In the normal temperature, the ratio of the elastic modulus between the basalt fiber concrete and the asphalt concrete is 24: 1.

Advantages of Reinforcemet Mesh from Basalt Fiber

Basalt fibre concrete has the excellent resistance to deformation, the elongation at break is about 3.1%. Basalt Fiber owns the high-temperature resistance, frost resisting resistance (-260~650 ℃), the same thermal expansion coefficient with the asphalt concrete, the high tensile strength, ultraviolet resistance, the stable chemical resistance, ageing resistance. The stirring temperature of the asphalt concrete is up to 190℃. The high-temperature Basalt fiber is the best alternative of the polyester fiber. It can satisfy the asphalt stirring temperature (190 ℃), and it is the excellent construction material for reinforced cement & concrete, and it has the outstanding penetration resistance.

Basalt geogrid/geotextile is more durable than metallic and glass-fiber reinforcement due to basalt fiber’s excellent performance.

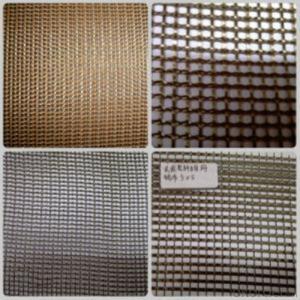

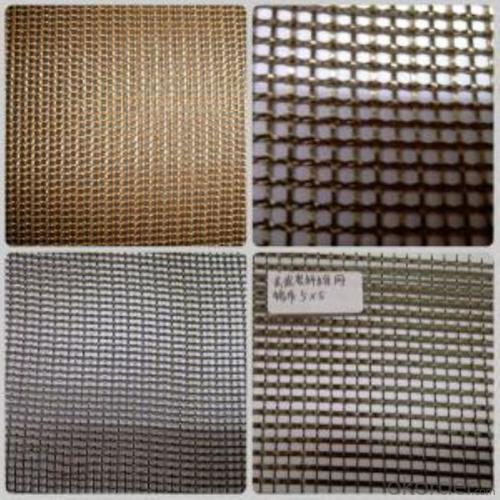

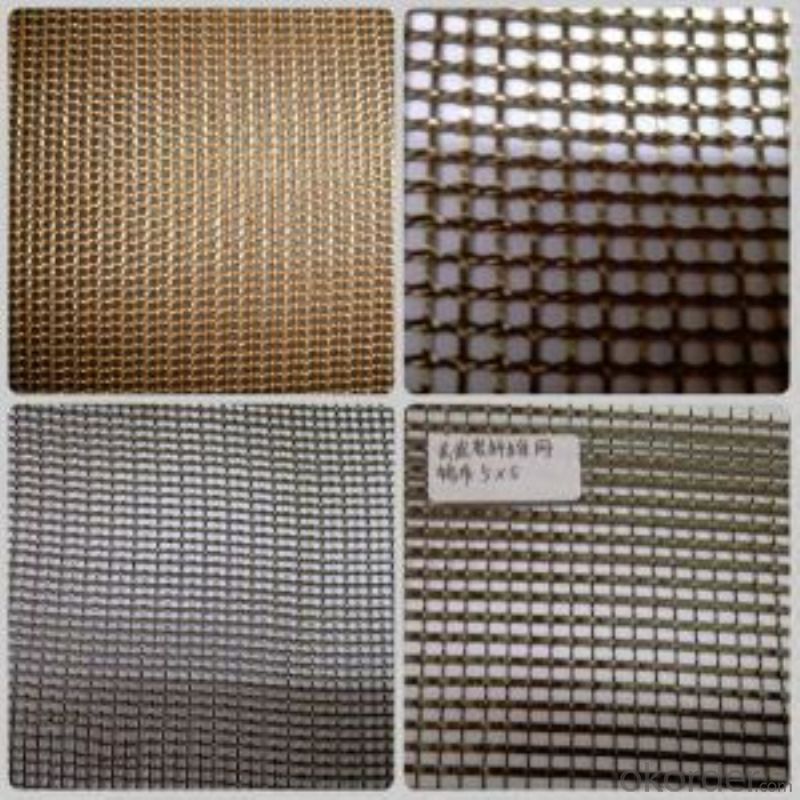

Specifications of Reinforcemet Mesh from Basalt Fiber

Item No. | Weight (g/m2) | Size (mm) | Thickness (mm) | Width (mm) | Roll Length (m) |

CMAX-250 | 250 | 5X5 | 0.6-0.7 | 300-2000 | 50m~100m |

CMAX-120 | 165 | 10X10 | 0.7-0.8 | 300-2000 | 50m~100m |

CMAX-300 | 350 | 25X25 | 0.8-0.9 | 300-2000 | 50m~100m |

Application of Reinforcemet Mesh from Basalt Fiber

-laying of cement concrete pavement

-the reinforcement of the piers, dams,road and buildings

-building surface drywall joints

-cement mortar or concrete pouring

FAQ:

1. Which payment do you accept?

For you convinience, our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

4. When will you reply my request?

You are our expected customer, we’ll reply your request within 24hours. Please feel free to contact us at any time.

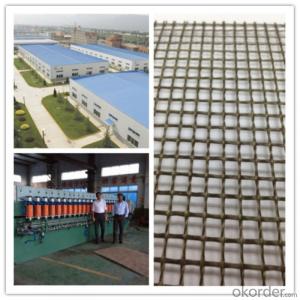

Photo of Reinforcemet Mesh from Basalt Fiber

- Q: Modified asphalt and basalt asphalt

- Basalt asphalt and modified asphalt are used in road and other road use and maintenance, are the traditional asphalt material of an improvement and optimization.

- Q: The difference between basalt and basalt

- According to alkalinity, can be divided into alkaline basalt, transition basalt, pull basalt, calc-alkaline basalt and potassium rock. According to the formation of the environment, including the formation of land in the continental environment of the overflowing basalt and formed in the submarine expansion of the oceanic basalt. So the road overflow basalt is named because of the formation, alkaline basalt is determined by the alkalinity

- Q: Basalt and limestone Which rocks are not suitable for building materials? why

- Mainly from easy weathering, corrosion, and moisture aspects to consider! The latter is not suitable.

- Q: The difference between basalt and limestone

- Basalt is the main component of silica, aluminum oxide, iron oxide, calcium oxide, magnesium oxide (and a small amount of potassium oxide, sodium oxide), which contains the largest silica, accounting for about 45 percent to About fifty Basalts are mostly black, dark brown or dark green, and because of their dense texture, the proportion of granite, limestone, sandstone and shale is heavy, but some basalts are much more , Even in the water can float up.Therefore, this kind of porous body light basalt, called "pumice".

- Q: Basalt and limestone Which rocks are not suitable for building materials? Why?

- Basalts are mostly black, dark brown or dark green, and because of their dense texture, the proportion of granite, limestone, sandstone and shale is heavy, but some basalts are much more , Even in the water can float up.Therefore, this kind of porous body light basalt, called "pumice". According to the structure, can be divided into stomatal basalt, almond-shaped basalt, etc .; according to the chemical composition and mineral composition, can be divided into high-alumina basalt, basalt, basalt, Alkaline basalt and pull basalt.

- Q: What is the difference between basalt and rhyolite?

- Basalt is the main component of sodium aluminosilicate or calcium aluminosilicate, silica content of 45% to 52%, also contains high iron oxide and magnesium oxide, is a dense dense black rock.

- Q: What is the characteristic of basalt?

- The bulk density of basalt is 2.3.3g / cm3, and its compact structure has a large compressive strength of 300MPa or even higher, but if the crystal impurity and porosity are used, the strength will decrease.

- Q: Basalt and diabase which is expensive

- In general, the rock mineral particles are as fine as possible. The basalt is the formation of the role of volcanoes, generally there are pores exist, the color can not be compared with the diabase than the United States, the hardness level is also less than diabase, so that the price of diorite is very normal.

- Q: What is the use of basalt?

- A rock of a dense or foamy structure that is solidified by volcanic eruptions from volcanic eruptions, which belongs to magmatic rocks (also called igneous rocks) in the classification of geology rocks. The magma temperature of volcanic eruptions Up to 1200 degrees Celsius, due to a certain degree of viscosity, in the gentle terrain, the magma flow is very slow, only a few meters per minute flow; encountered steep slope, the speed will be greatly accelerated in the flow process, carrying a lot of water Steam and air bubbles, after cooling, they formed a variety of variations in the shape of the temple of Hubei waterfall-like, wavy; Yingge Ling area with round bread-like, pagoda-like; Bohai Town and Shalan Township, is a giant Python and lava tunnel, etc. Geology, geomorphic structure of the new Ying, different shapes, colorful.

- Q: Granite, limestone and basalt from the color and appearance how to distinguish

- The basalt has a clear bubble look, because he is the product of the volcanic eruption, the granite is relatively smooth, there are many products such as muscovite feldspar quartz, marble is not the first two hard, with the geological hammer ringing sound, limestone with hydrochloric acid to see No bubbles.

Send your message to us

Road Wall Reinforcement Mesh from Basalt Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6500 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords