Galvanized Hexagonal Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

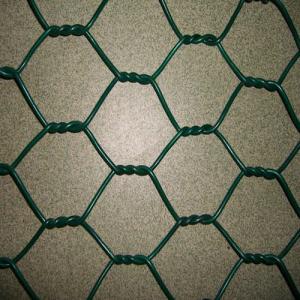

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

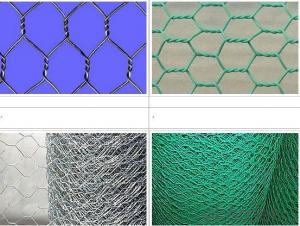

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How does steel wire mesh perform in terms of transparency?

- Steel wire mesh does not offer high transparency as the interwoven steel wires create a solid barrier, limiting the amount of light or visibility that can pass through.

- Q: How does the coating affect the resistance of steel wire mesh to chemicals?

- The resistance of steel wire mesh to chemicals greatly depends on the coating applied. The coating functions as a protective layer, preventing direct contact between the mesh and corrosive substances, thus reducing the chance of chemical reactions. Various coatings offer different levels of chemical resistance. For example, a polyvinyl chloride (PVC) coating exhibits excellent resistance to acids, alkalis, and other corrosive chemicals. Conversely, an epoxy coating provides high resistance to solvents, oils, and hydrocarbons. The thickness and quality of the coating also influence the mesh's resistance to chemicals. Thicker coatings offer better protection by creating a more substantial barrier between the wire and corrosive substances. Additionally, high-quality coatings are designed to withstand prolonged exposure to chemicals without deteriorating or easily wearing off. When selecting the appropriate coating, it is crucial to consider the specific chemicals the mesh will encounter in its intended application. This ensures compatibility between the coating and the chemicals, maximizing the mesh's resistance to chemical corrosion. In conclusion, the coating applied to steel wire mesh plays a vital role in its chemical resistance. The type, thickness, and quality of the coating determine the level of protection, emphasizing the importance of choosing a suitable coating for the intended chemical environment.

- Q: How is steel wire mesh used in reinforcement of residential buildings?

- Steel wire mesh is commonly used in the reinforcement of residential buildings to enhance the structural integrity and durability of concrete structures. It is mainly used in areas where concrete is prone to cracking or where additional strength is required. One of the primary applications of steel wire mesh in residential buildings is in the construction of concrete slabs. The steel mesh is placed in the middle of the slab, creating a reinforcement layer that helps distribute the load evenly and prevent cracking. This is particularly important in areas with heavy foot traffic or where heavy loads such as furniture or appliances will be placed. Steel wire mesh is also used in the reinforcement of concrete walls. It is typically placed in the middle of the wall, parallel to the surface, to provide additional strength and prevent cracking. This is especially crucial in areas prone to seismic activity or where the soil conditions may cause the walls to shift or settle. In addition to slabs and walls, steel wire mesh is also used in the reinforcement of residential building foundations. By placing the mesh below the concrete footing, it helps distribute the load more evenly and prevents the foundation from cracking or settling. This is particularly important in areas with unstable soil or where the water table is high. Overall, steel wire mesh plays a crucial role in the reinforcement of residential buildings by providing additional strength and preventing cracking. It helps improve the longevity and stability of the building, ensuring that it can withstand various external forces such as heavy loads, seismic activity, and soil movements.

- Q: How does steel wire mesh perform in electromagnetic shielding applications?

- Steel wire mesh is highly effective in electromagnetic shielding applications. It acts as a Faraday cage, which means it can block and divert electromagnetic radiation. The interwoven steel wires create a conductive barrier that absorbs and reflects electromagnetic waves, preventing them from passing through. This makes steel wire mesh an excellent choice for applications where electromagnetic interference needs to be minimized, such as in electronic devices, data centers, and sensitive scientific equipment.

- Q: What are the different welding methods used for steel wire mesh?

- Steel wire mesh can be welded using various methods, each with its own benefits and suitability for specific uses. Commonly employed welding techniques for steel wire mesh include: 1. Resistance Spot Welding: This method utilizes electric current to generate heat and pressure, effectively joining wires at specific points. It is a rapid and efficient welding approach suitable for mass production of steel wire mesh. 2. Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, GMAW involves a consumable wire electrode and a shielding gas to protect the weld from atmospheric contamination. It offers excellent control over the welding process and is commonly used for welding thinner wire mesh. 3. Gas Tungsten Arc Welding (GTAW): Also referred to as TIG (Tungsten Inert Gas) welding, GTAW employs a non-consumable tungsten electrode and a shielding gas to create the weld. It provides precise control, high-quality welds, and is often used for welding stainless steel wire mesh. 4. Flux-Cored Arc Welding (FCAW): This method employs a tubular wire electrode filled with flux, eliminating the need for a shielding gas. FCAW is popular for outdoor applications or environments with wind, as the flux safeguards the weld from atmospheric contamination. 5. Laser Welding: Laser welding employs a powerful laser beam to melt and unite the wires. It offers exceptional precision and can be used for welding very fine wire mesh, albeit at a higher cost compared to other methods. The selection of the appropriate welding method for steel wire mesh depends on factors such as wire diameter, required weld strength, production volume, and specific application. Each method has its own advantages and limitations, necessitating careful consideration of these factors to ensure optimal welding method selection for steel wire mesh fabrication.

- Q: Can steel wire mesh be used for creating conveyor belts or filters?

- Yes, steel wire mesh can definitely be used for creating conveyor belts or filters. Steel wire mesh is a versatile material that offers high strength, durability, and excellent resistance to corrosion, making it ideal for various industrial applications. When used for conveyor belts, steel wire mesh provides a reliable and efficient method of transporting materials. Its open weave design allows for easy airflow and drainage, making it suitable for industries such as mining, food processing, and construction. The strength of the steel wire mesh ensures that the conveyor belt can handle heavy loads and withstand the rigors of continuous operation. Similarly, steel wire mesh is commonly used in filters due to its ability to effectively separate particles and contaminants from a fluid or gas. The mesh size can be customized to meet specific filtration requirements, allowing for precise control over the filtration process. The durability and corrosion resistance of steel wire mesh make it a long-lasting and cost-effective choice for filters, especially in industries such as oil and gas, water treatment, and automotive. Overall, steel wire mesh is a versatile material that can be utilized for creating conveyor belts and filters. Its strength, durability, and resistance to corrosion make it a reliable choice for various industrial applications where efficient material transportation or filtration is required.

- Q: What are the different mesh shapes available for steel wire mesh?

- The different mesh shapes available for steel wire mesh include square, rectangular, hexagonal, diamond, and expanded metal.

- Q: How does steel wire mesh perform in high-humidity environments?

- Steel wire mesh performs well in high-humidity environments due to its inherent properties and durability. Steel is known for its resistance to corrosion, making it a suitable material for applications in wet and humid conditions. The wire mesh is typically galvanized or coated with a protective layer, further enhancing its resistance to moisture and preventing rusting. In high-humidity environments, steel wire mesh maintains its structural integrity and strength. It does not warp, deform, or lose its shape, ensuring consistent performance over time. The mesh's open design allows for proper ventilation and airflow, preventing the accumulation of moisture that could lead to condensation or mold growth. Moreover, steel wire mesh is commonly used in various industries, including construction, agriculture, and manufacturing, where it is exposed to high humidity levels. It is often employed in concrete reinforcement, fencing, animal enclosures, and filtration systems, among other applications. While steel wire mesh is generally resilient in high-humidity environments, it is essential to select the appropriate grade and coating to suit the specific conditions. This ensures optimal performance and prolongs the lifespan of the mesh. Regular maintenance and cleaning should also be conducted to remove any accumulated debris or moisture, further preserving its functionality and appearance.

- Q: Is steel wire mesh resistant to fire?

- Generally, steel wire mesh is resistant to fire. This is because steel has a high melting point and low thermal conductivity, making it highly fire-resistant. When exposed to fire, steel wire mesh does not easily burn or ignite. Instead, it maintains its structural integrity and acts as a barrier to prevent the spread of flames. Moreover, steel wire mesh does not release toxic fumes or emit harmful gases when exposed to high temperatures, further enhancing its fire resistance. However, it's important to note that the fire resistance of steel wire mesh can vary depending on factors such as thickness, quality, and any additional coatings or treatments it has undergone. Therefore, it is advisable to consult the manufacturer or refer to specific fire ratings and certifications for a more accurate assessment of its fire resistance capabilities in different applications.

- Q: Does steel wire mesh corrode?

- Yes, steel wire mesh can corrode. Corrosion is a natural process that occurs when metals are exposed to oxygen and moisture over time. Steel, including steel wire mesh, is prone to corrosion due to the presence of iron in its composition. When the mesh is exposed to corrosive elements, such as saltwater or acidic environments, it can undergo a chemical reaction known as oxidation, which results in the formation of rust. This rust not only weakens the integrity of the mesh but can also lead to its eventual degradation if left untreated. Therefore, it is important to regularly inspect and maintain steel wire mesh to prevent and mitigate corrosion.

Send your message to us

Galvanized Hexagonal Wire Netting After Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords