Weled trench reinforcing rebar mesh for best quanlity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material | Low carbon steel, Ribbed steel, Deformed steel bar |

Type | Welded Mesh |

Standard | AISI, ASTM, BS DIN, GB, JIS |

Usage | Construction Reinforcement |

Hole Shape | Square |

Weave Style | Reinforcing mesh, Welded |

Product Code | Std Unit | Longitudinal Wires | Cross Wires | Mass(kg) | Dimensions(m) |

SL52 | sheet | 10×4.77@200+4×4@100 | 30×4.77@200 | 21 | 6×2.4 |

SL62 | sheet | 10×6@200+4×4.77@100 | 30×6@200 | 33 | 6×2.4 |

SL72 | sheet | 10×6.75@200+4×4@100 | 30×6.75@200 | 41 | 6×2.4 |

SL81 | sheet | 25×7.6@100 | 60×7.6@200 | 105 | 6×2.4 |

SL82 | sheet | 10×7.6@200+4×5.37@100 | 30×7.6@200 | 52 | 6×2.4 |

SL92 | sheet | 10×8.6@200+4×6@100 | 30×8.6@200 | 66 | 6×2.4 |

SL102 | sheet | 10×9.5@200+4×6.75@100 | 30×9.5@200 | 80 | 6×2.4 |

×Diameter (mm) × Spacing (mm) | |||||

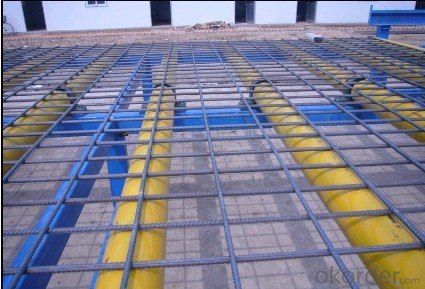

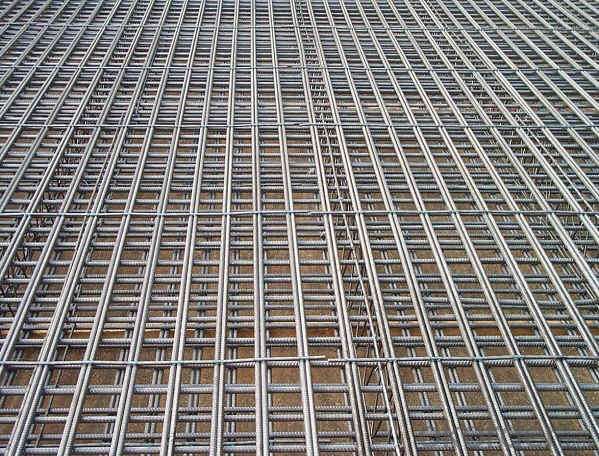

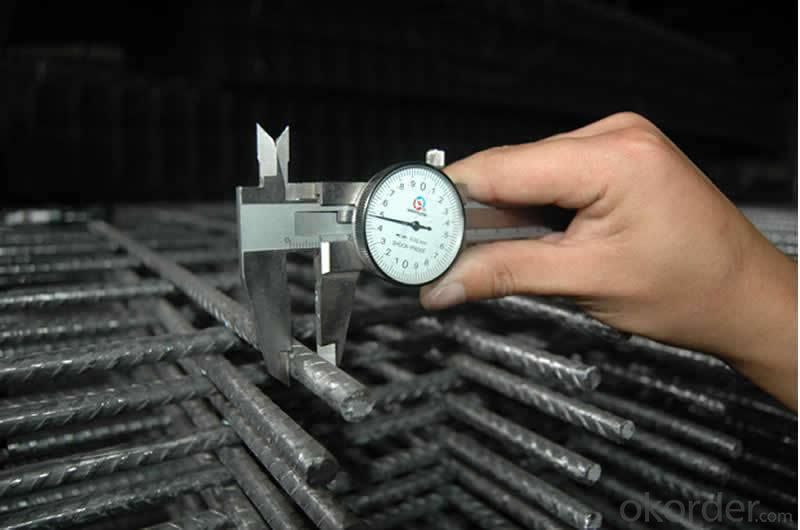

Product Display

Reinforcing wire mesh is a welded wire fabric, prefabricated steel reinforcement material.

It's made of Deformed Steel Bars or Steel Rod.

Wire diameter | 3mm-14mm |

Mesh size | 5*125px,10*250px,10*500px, 20*500px,10*750px,30*750px |

space | 50*50-200*200mm |

The fabric is used to provide tensile strength and crack control to structural concrete elements.

Welded mesh reinforcing is a convenient and cost effective alternative to conventional bar reinforcement for the following reasons:

1. The mesh is generally specified and manufactured according to standard references making for easy site identification, quality control and management.

2.The mesh is manufactured in sheets or rolls resulting in a quick and simple site installation process.

Application

1.Welded reinforcement steel wire mesh is widely used in construction filed,like housing floor, roof wall, terrace, concrete pavement.

2.Welded reinforcement steel wire mesh is also used in deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian.

3.Welded Wire Mesh can be used in wall,road for reinforcement.

- Q: Can steel wire mesh be customized to specific requirements?

- Steel wire mesh has the capability to be tailored according to specific needs. This versatile material can be modified to meet a variety of specifications and applications. It offers the flexibility to adjust wire diameter, mesh size, and overall dimensions in order to fit specific requirements. Moreover, different weaving patterns such as plain, twill, or Dutch weave can be utilized to achieve desired characteristics such as strength, flexibility, or filtration capabilities. Furthermore, surface treatments like galvanization or coating can be applied to enhance corrosion resistance or improve appearance. These customizable options make steel wire mesh suitable for a wide range of industries and applications including construction, infrastructure, industrial processes, and filtration systems.

- Q: What is the maximum width of steel wire mesh available?

- Various factors, such as the specific manufacturer, type of mesh, and intended application, influence the maximum width of steel wire mesh that is available. Typically, steel wire mesh is offered in standard widths ranging from 36 inches (91.44 cm) to 72 inches (182.88 cm). Nevertheless, certain manufacturers are capable of producing custom sizes and widths to meet specific project requirements. To determine the maximum width available for a particular type of steel wire mesh, it is recommended to consult with a supplier or manufacturer.

- Q: Is steel wire mesh suitable for gabion baskets?

- Yes, steel wire mesh is suitable for gabion baskets. Gabion baskets are typically used for erosion control, retaining walls, and slope stabilization, and steel wire mesh provides the necessary strength and durability for these applications. Steel wire mesh is resistant to corrosion, which is important when the baskets are exposed to outdoor elements. Additionally, the open design of the mesh allows for proper drainage and prevents the buildup of water pressure behind the baskets. Steel wire mesh is also easy to assemble and install, making it a practical choice for gabion basket construction.

- Q: What are the different surface patterns available for steel wire mesh?

- Steel wire mesh is available in various surface patterns, each possessing unique characteristics and serving distinct purposes. Some commonly used surface patterns comprise: 1. Plain Weave: This surface pattern, the most basic and prevalent, involves weaving wires together in a straightforward over-under manner. It imparts a balanced and uniform appearance, rendering it suitable for a wide array of applications. 2. Twill Weave: In this pattern, wires are woven diagonally, creating a pronounced twill effect. Twill weave offers enhanced strength and durability compared to plain weave, making it ideal for heavy-duty applications like filtration or reinforcement. 3. Dutch Weave: Dutch weave consists of tightly woven warp wires and coarser weft wires, resulting in a dense mesh with smaller openings. This pattern boasts excellent filtration capabilities and is often utilized in applications requiring precise particle retention, such as chemical processing or oil filtration. 4. Welded Mesh: Unlike woven mesh, welded mesh is formed by welding individual wires together at their intersections. This pattern offers high strength and rigidity, making it perfect for applications necessitating additional structural support, like fencing or security barriers. 5. Expanded Metal: Expanded metal mesh is created by cutting and stretching a metal sheet, resulting in an open pattern with diamond-shaped holes. This pattern provides an excellent strength-to-weight ratio and allows for adequate airflow and visibility, making it suitable for applications such as walkways, grating, or architectural facades. Ultimately, the selection of a surface pattern for steel wire mesh relies on the specific requirements of the application, encompassing factors such as strength, filtration capabilities, visibility, and aesthetic appeal.

- Q: How does steel wire mesh perform in high-temperature environments?

- Steel wire mesh performs well in high-temperature environments due to its excellent heat resistance and durability. It retains its structural integrity and does not deform or melt under intense heat, making it suitable for applications such as furnace linings, exhaust systems, and heat shields. Additionally, steel wire mesh can effectively dissipate heat, preventing overheating and potential damage to surrounding equipment or structures.

- Q: Is steel wire mesh resistant to fire?

- Yes, steel wire mesh is generally resistant to fire. Steel is a highly fire-resistant material due to its high melting point and low thermal conductivity. When steel wire mesh is exposed to fire, it does not easily burn or ignite. Instead, it retains its structural integrity and can act as a barrier to prevent the spread of flames. The fire resistance of steel wire mesh is further enhanced by the fact that it does not release toxic fumes or emit harmful gases when exposed to high temperatures. However, it is important to note that the fire resistance of steel wire mesh can vary depending on its thickness, quality, and any additional coatings or treatments it may have undergone. It is advisable to consult the manufacturer or refer to specific fire ratings and certifications for a more accurate assessment of its fire resistance capabilities in different applications.

- Q: How does steel wire mesh perform in terms of airflow?

- Steel wire mesh performs well in terms of airflow. The open structure of the mesh allows for the passage of air, making it an effective material for ventilation and air circulation purposes.

- Q: How is steel wire mesh used in reinforcement of bridges and viaducts?

- Steel wire mesh is used in the reinforcement of bridges and viaducts by providing additional strength and stability to the concrete structures. The mesh is placed within the concrete during construction, acting as a reinforcement framework that helps distribute loads and prevent cracking or structural failure. By reinforcing the concrete, steel wire mesh increases the overall strength and durability of the bridge or viaduct, ensuring its ability to withstand heavy traffic and environmental forces.

- Q: Is steel wire mesh suitable for use in soundproofing applications?

- Soundproofing applications can benefit greatly from the use of steel wire mesh. This versatile material, also known as acoustic mesh or soundproof mesh, has unique properties that make it effective in blocking and absorbing sound waves. It is commonly used in architectural projects, industrial applications, and even residential settings. The density and sturdiness of steel wire mesh allow it to effectively block the transmission of sound waves. Its mesh structure disperses and absorbs sound waves, resulting in reduced noise levels. This material can be customized to fit different soundproofing requirements, with options available in terms of thickness, patterns, and sizes. It can be installed as screens, panels, or wraps depending on the specific application and desired level of soundproofing. Steel wire mesh is also highly durable and able to withstand harsh environmental conditions. It is corrosion-resistant, fire-resistant, and can handle high temperatures, making it suitable for both indoor and outdoor soundproofing applications. To sum up, steel wire mesh is an excellent choice for soundproofing due to its ability to effectively block and absorb sound waves. Its versatility, durability, and customizable options make it suitable for a wide range of soundproofing projects.

- Q: What are the different wire mesh finishes available in steel wire mesh?

- There are several different wire mesh finishes available in steel wire mesh, including galvanized, PVC coated, epoxy coated, and stainless steel.

Send your message to us

Weled trench reinforcing rebar mesh for best quanlity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords