Grp Reinforcement

Grp Reinforcement Related Searches

Grp Reinforced Plastic Frp And Grp Reinforcement Grid Grp Glass Reinforced Polyester Grp Flange Grp Lamination Reinforcement Material Composite Grp Geogrid Base Reinforcement Grp Pipe Lamination Slope Reinforcement Geogrid Geogrid Pavement Reinforcement Grp Pipe Full Form Geogrid Asphalt Reinforcement Geogrid Reinforced Slope Deflection Test For Grp Pipes Geogrid Reinforced Foundation Amiantit Grp Pipes Geogrid Reinforcing Fabric Geogrid Reinforcement Mesh Gps Tracking Power Generation Distribution Motorized Drapery Frp Pultrusion Geogrid Reinforced Earth Wall Graphite Corrosion Resistance Geogrid Reinforced Soil Dvr Surveillance Rfp Pipe Temporary Power DistributionGrp Reinforcement Supplier & Manufacturer from China

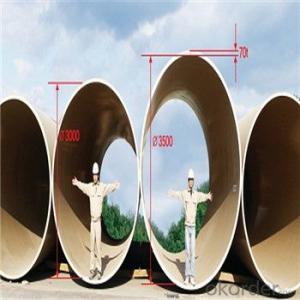

GRP Reinforcement is a composite material that combines the strength of glass fibers with the durability of resin, resulting in a versatile product that is widely used in various industries. This product is known for its high strength-to-weight ratio, resistance to corrosion, and ease of installation, making it an ideal choice for applications such as construction, marine, and transportation sectors.The application and usage scenarios of GRP Reinforcement are extensive, as it can be utilized in the manufacturing of pipes, tanks, and structural components that require high strength and resistance to harsh environments. It is also commonly used in the production of wind turbine blades, where its lightweight and strong properties are particularly beneficial. Additionally, GRP Reinforcement is employed in the creation of electrical insulators and in the reinforcement of concrete structures, showcasing its adaptability across different fields.

Okorder.com is a leading wholesale supplier of GRP Reinforcement, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the GRP Reinforcement products it offers meet the highest industry standards. This extensive inventory allows Okorder.com to provide a one-stop solution for businesses looking to incorporate GRP Reinforcement into their projects, streamlining the procurement process and ensuring timely delivery.

Hot Products